Greater flexibility in product design

While featuring low birefringence comparable to glass, being a resin AZP™ offers superior processability enabling flexible product design. Furthermore, AZP™ can maintain its low birefringence even under stress. This provides consistent performance in lenses and specially shaped displays, enhancing both product quality and the user experience.

Design without shape constraints

Although AZP™ features low birefringence comparable to glass, it is a thermoplastic resin that can be injection molded. This allows more innovative and flexible designs by enabling curved surfaces and complex shapes that would be difficult to create with conventional glass.

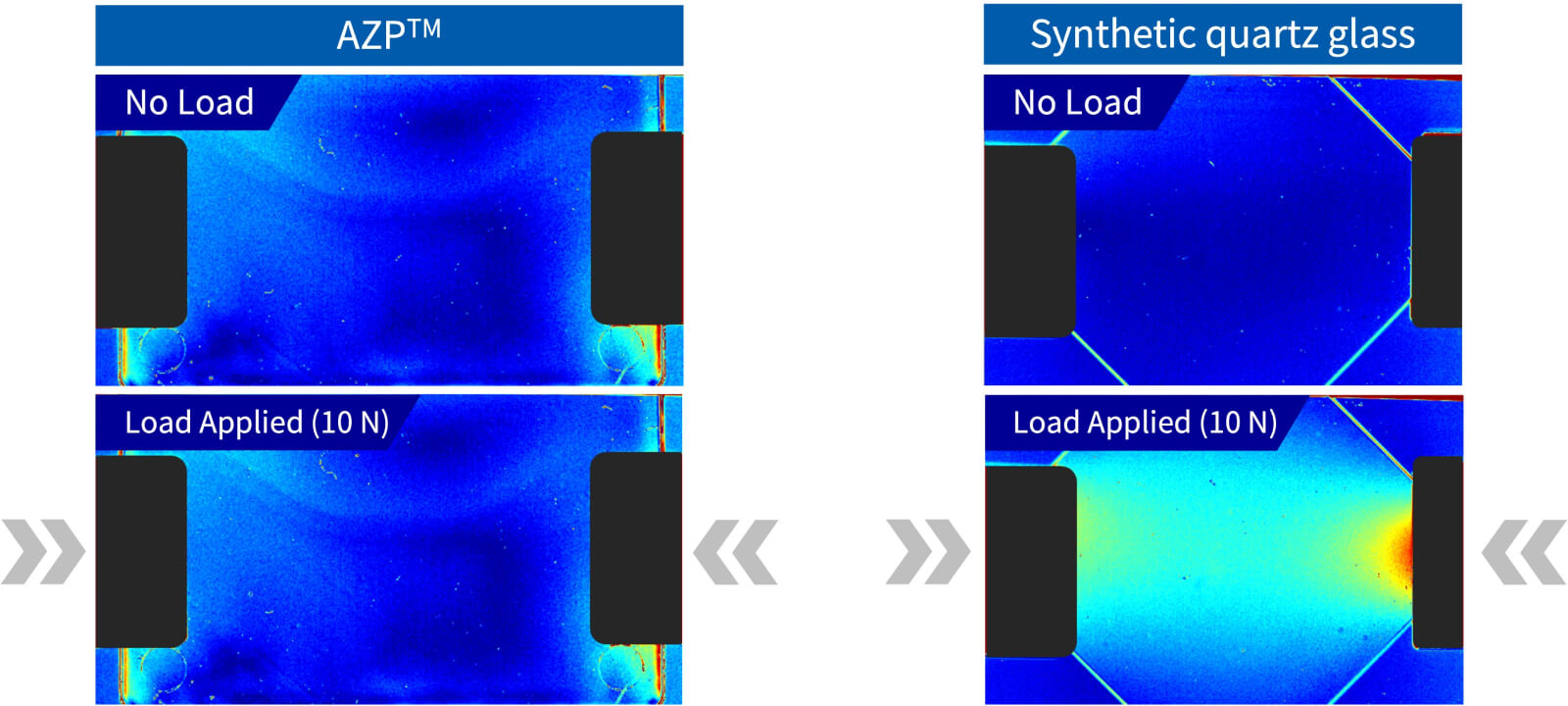

Maintaining low birefringence even under stress

With glass and conventional resins, birefringence can arise due to stress induced during processing and assembly. In VR headset lenses, for example, stress induced by adhesion to the adapter can cause birefringence around the outer edges, impairing visibility. AZP™ maintains its excellent low birefringence even under stress, enabling more flexible product designs.