Almost no birefringence

With AZP™ optical resin from Asahi Kasei, both "orientation birefringence," which occurs due to molding of the resin, and "stress birefringence," which is caused by applied stress, are extremely low. AZP™ makes it possible to resolve birefringence-related issues that have traditionally occurred in optical components.

Low birefringence comparable to glass

AZP™ optical resin has low birefringence comparable to glass. This remarkable characteristic of AZP™ sets it apart from conventional optical resins, making it a viable substitute for glass in components where issues of birefringence tend to occur.

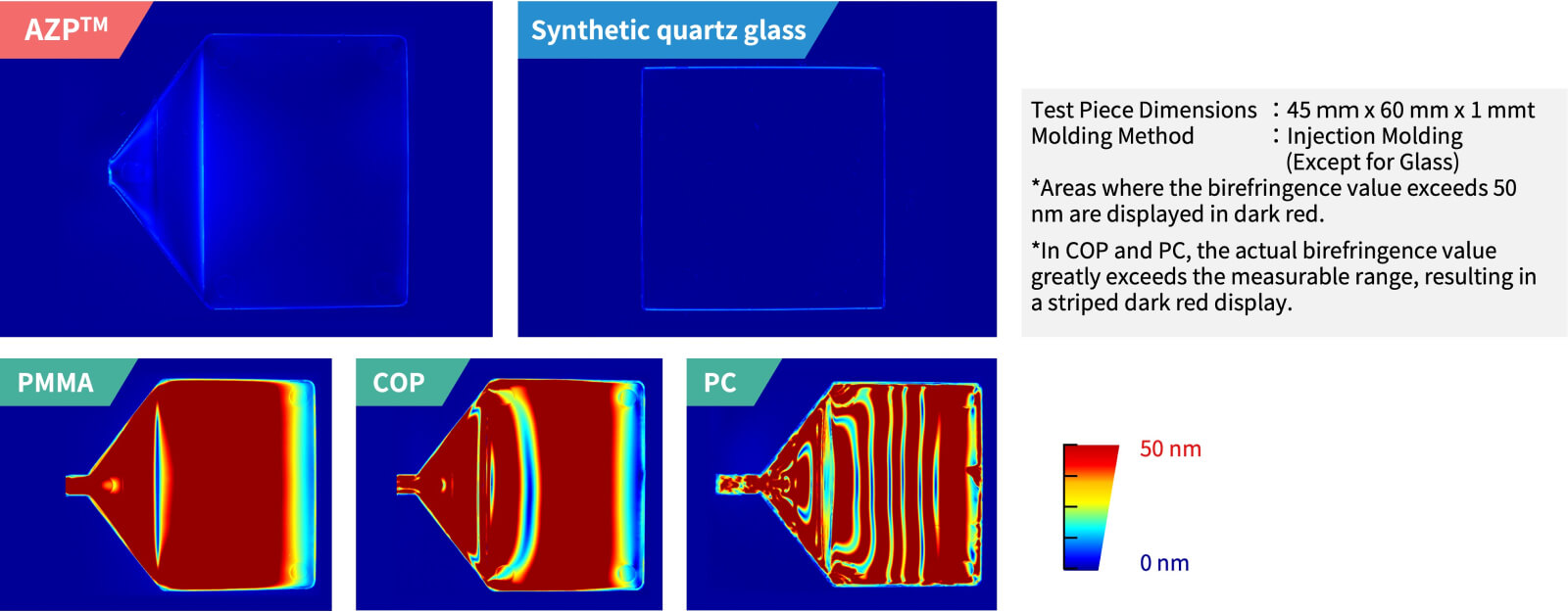

To demonstrate, we injection-molded AZP™ along with three conventional optical resins into plate form, and compared their birefringence with a plate of glass. As you can see below, AZP™ exhibits almost no birefringence, similar to glass. The conventional optical resins, in contrast, show significant birefringence.

The difference arises because AZP™ has extremely low "orientation birefringence," which occurs during injection molding. By using AZP™ as a substitute for glass in optical components, you can avoid issues of birefringence that occur with conventional optical resins.。

Low birefringence maintained even under stress

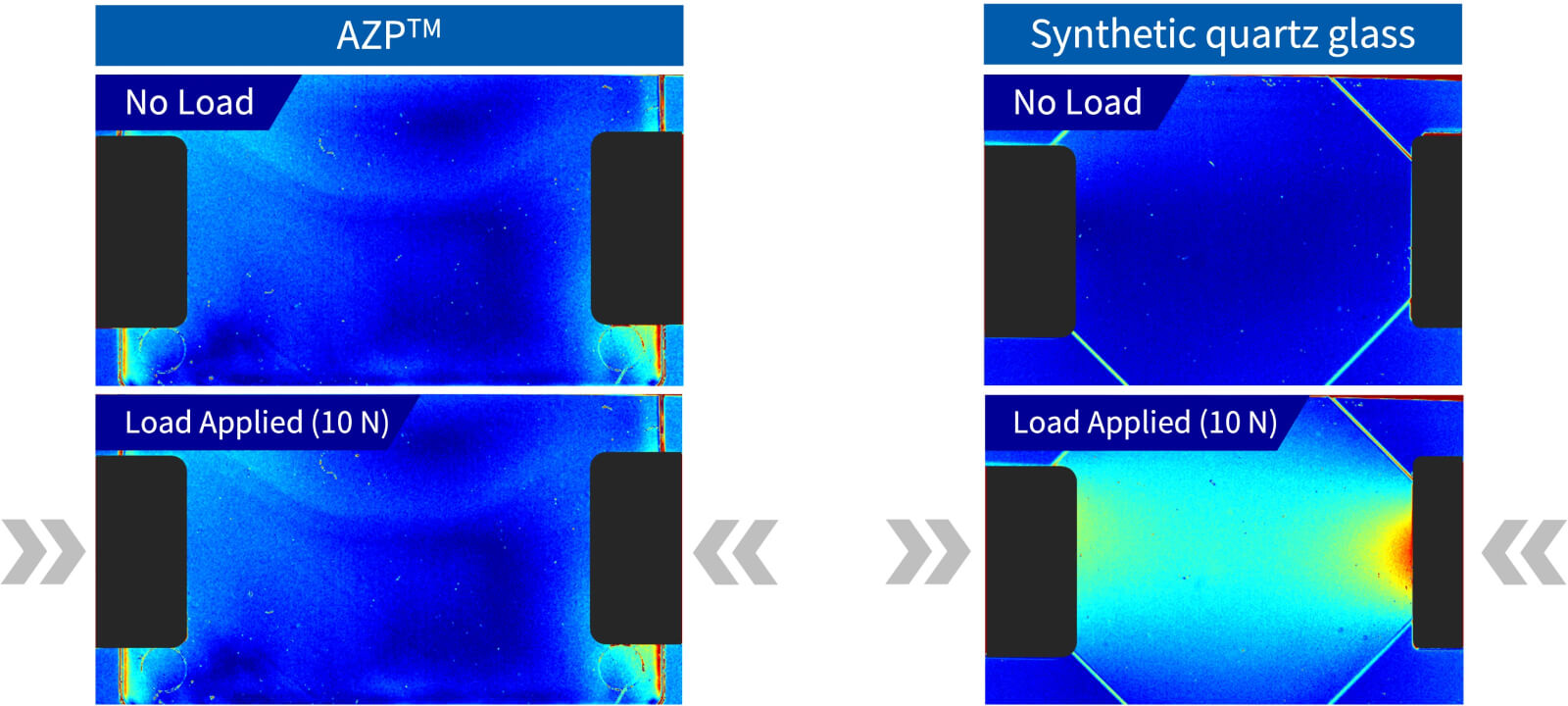

With conventional optical components made of glass, birefringence can arise due to stress induced during assembly. In contrast, AZP™ maintains its low birefringence even under stress.

To examine the effects of stress, we compared the birefringence of AZP™ and synthetic quartz glass under a 10 N load. As you can see below, the glass exhibited birefringence under the applied load, while AZP™ shows no observable birefringence.

This illustrates how the "stress-induced birefringence" of AZP™ is extremely low. As such, AZP™ can help resolve issues related to visibility caused by stress-induced birefringence.

More precise image formation

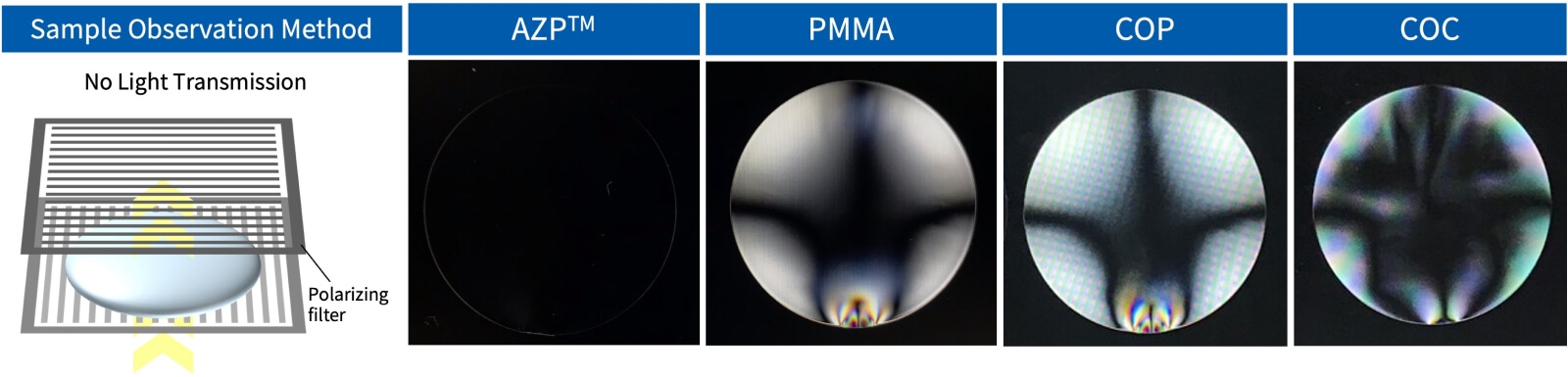

Lenses made from conventional optical resins inevitably have significant birefringence which causes ghosting and flaring with pancake lenses or other optical systems that utilize polarization. With its extremely low birefringence, AZP™ can resolve these issues that are common to lenses made of resin.

We compared the birefringence of lenses injection-molded using AZP™ and three conventional optical resins. As you can see below, the lens made of AZP™ shows very little birefringence, while the lenses made of conventional optical resins show significant birefringence.

This result for AZP™ is due to its very low "orientational birefringence" generated during injection molding as well as very low "stress-induced birefringence" due to residual stress after molding. Since lenses made of AZP™ lenses have such extremely low birefringence, they enable precise and clear image formation without blurring or distortion.