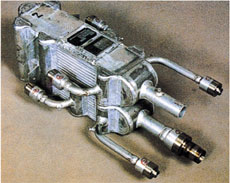

CCJTM

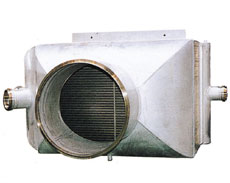

Asahi Kasei's bimetallic transition joint, CCJTM, is used to connect aluminum to stainless steel pipe. With its high reliability under the cryogenic condition and leakage resistance, it has been installed in many equipment all over the world.

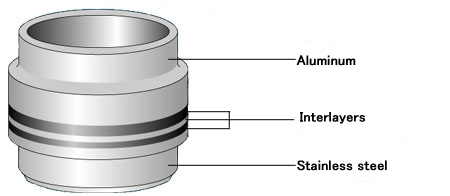

CCJTM is manufactured specifically for connection of dissimilar metals for use in cryogenic or high-vacuum lines, by machining explosion-bonded multi-layered BACLADTM plates to the following configuration.

- Direct welding of stainless and aluminum alloy pipes using CCJTM allows no leakage of liquide or gas which assures advantageous environmental safety.

- Smaller diameter, in comparison with flange connection, enables you to provide compact pipeline design.

- CCJTM is available for any size of pipes less than 76 inches.

- Bond strength between dissimilar metals is too great and stable to be affected by heat cycle.

※Please contact us for certification of ship classification, CRN or others.

CCJTM is manufactured to order, in nominal bore sizes from 3/4 to 76 inches.

LPG

Liquid nitrogen

LNG

Others

Note)

If the fluids are either oxygen, liquid oxygen, hydrogen or carbon monoxide,

they may cause the bad reaction, so please consult us.

(CCJTM-Ag can be used for those fluids.)

During welding work of stainless steel or aluminum pipe to CCJTM, the maximum allowable temperature at the bonded interfaces in CCJTM is 350°C× 30min.

Air separation plant, LNG Liquefier plant, etc

|

|

||

| Photograph courtesy of Kobe Steel Ltd. | Photograph courtesy of Sumitomo Precision Products Co. Ltd. |