High fluidity enables molding of large products

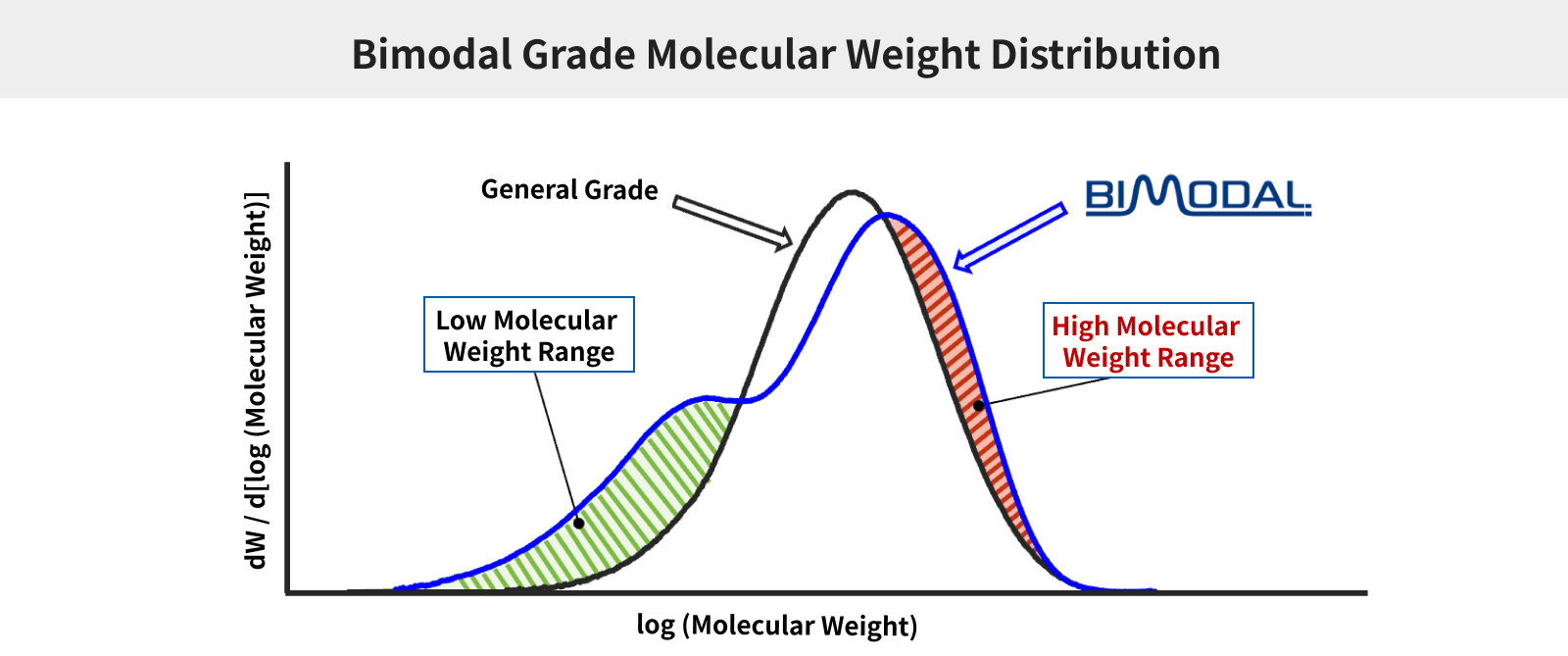

The DELPET™ Bimodal series is characterized by its bimodal molecular weight distribution. This characteristic allows it to maintain mechanical strength as well as high fluidity, making it possible to mold large-sized parts. It also has high solvent resistance, preventing cracking and roughness after molding.

Bimodal series details

Bimodal series features

Heat resistance, optical properties, and weather resistance equivalent to general grades

It can be molded at a lower temperature than conventional materials, making it possible to shorten the molding cycle.

High fluidity makes it excellent for injection molding

Excellent solvent resistance, and resistant to cracking and roughness after molding

Bimodal Series molecular weight data

* The property value is a representative value and not a guaranteed value.

Bimodal series applications

Tail lights of a car

Food containers (beer pitchers, soy sauce bags, measuring cups)

Vehicle emblems

Meter covers

Bimodal series physical properties

* The property value is a representative value and not a guaranteed value.

| Physical property items | Test method | Unit | Grade name | |||

| 80NE | 80NEN | 80EB | ||||

| High fluidity | Good fluidity | Solvent resistance | ||||

| 1. Flow characteristics | Melt flow-rate (230°C、37.3N) | 1133 | g/10min | 1.8 | 1.0 | 0.6 |

| Spiral length (wall thickness: 2mm, resin temperature: 250°C, mold temperature: 60°C, resin pressure: 75MPa) | Asahi Kasei PMMA method | cm | 33 | 30 | 27 | |

| 2. Mechanical Properties | Tensile modulus | 527-1/1A/1 | MPa | 3300 | 3300 | 3300 |

| Tensile breaking stress | 527-1/1A/5 | MPa | 77 | 77 | 77 | |

| Tensile failure strain | 527-1/1A/5 | % | 5 | 7 | 8 | |

| Bending elastic modulus | 178 | MPa | 3300 | 3300 | 3300 | |

| Bending strength | 178 | MPa | 130 | 130 | 130 | |

| Charpy impact strength without notch | 179/1eU | kJ/m2 | 22 | 24 | 24 | |

| Charpy impact strength notched | 179/1eA | kJ/m2 | 1.3 | 1.4 | 1.4 | |

| 3. Thermal Properties | Deflection temperature under load(1.8MPa) | 75-1,2 | °C | 100 | 98 | 98 |

| Vicat softening temperature | 306B50 | °C | 109 | 107 | 107 | |

| 4. Other Properties | Water absorption (23°C, 24hr) | 62method1 | % | 0.3 | 0.3 | 0.3 |

| Density | 1183 | g/cm3 | 1.19 | 1.19 | 1.19 | |

| Refractive index | 489 | - | 1.49 | 1.49 | 1.49 | |

| Total light transmittance | 13468-1 | % | 92 | 92 | 92 | |

| Rockwell hardness M scale | 2039-2 | - | 100 | 98 | 95 | |

| Mold shrinkage | Asahi Kasei PMMA method | % | 0.2~0.6 | 0.2~0.6 | 0.2~0.6 | |