Having a high level of jet black quality without the need for paint

Realize glossiness

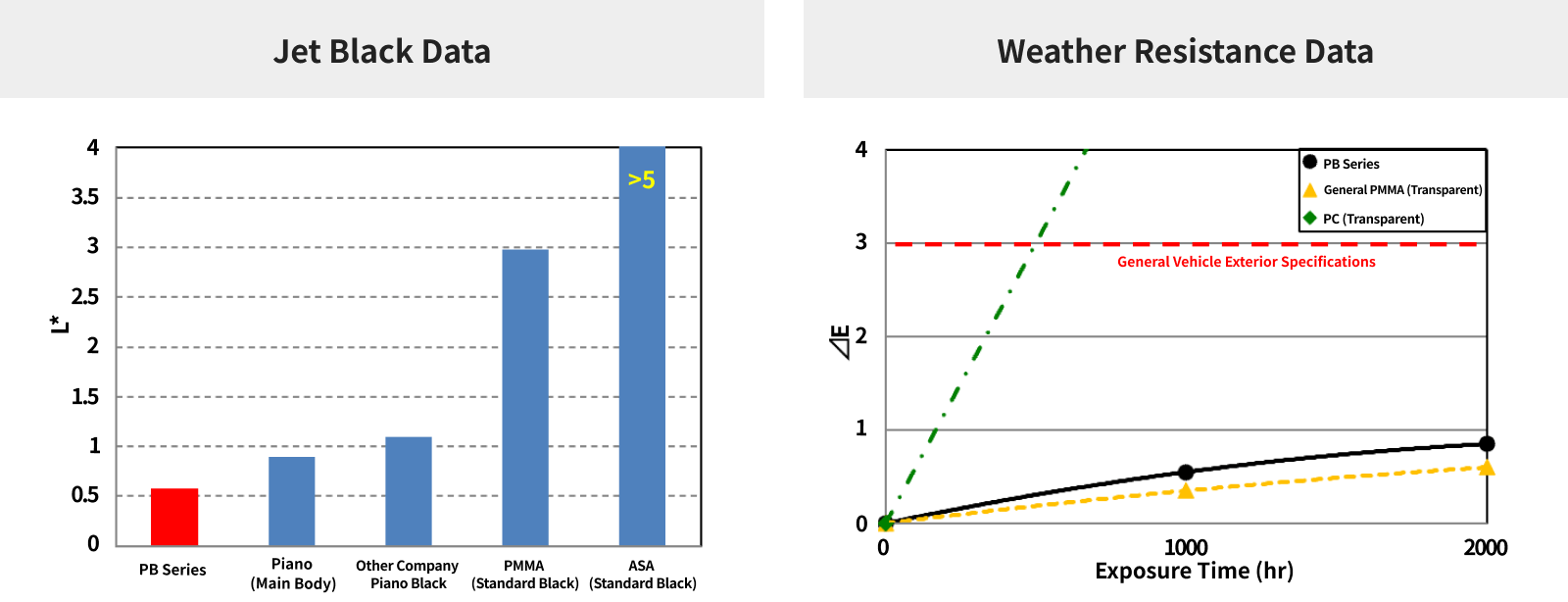

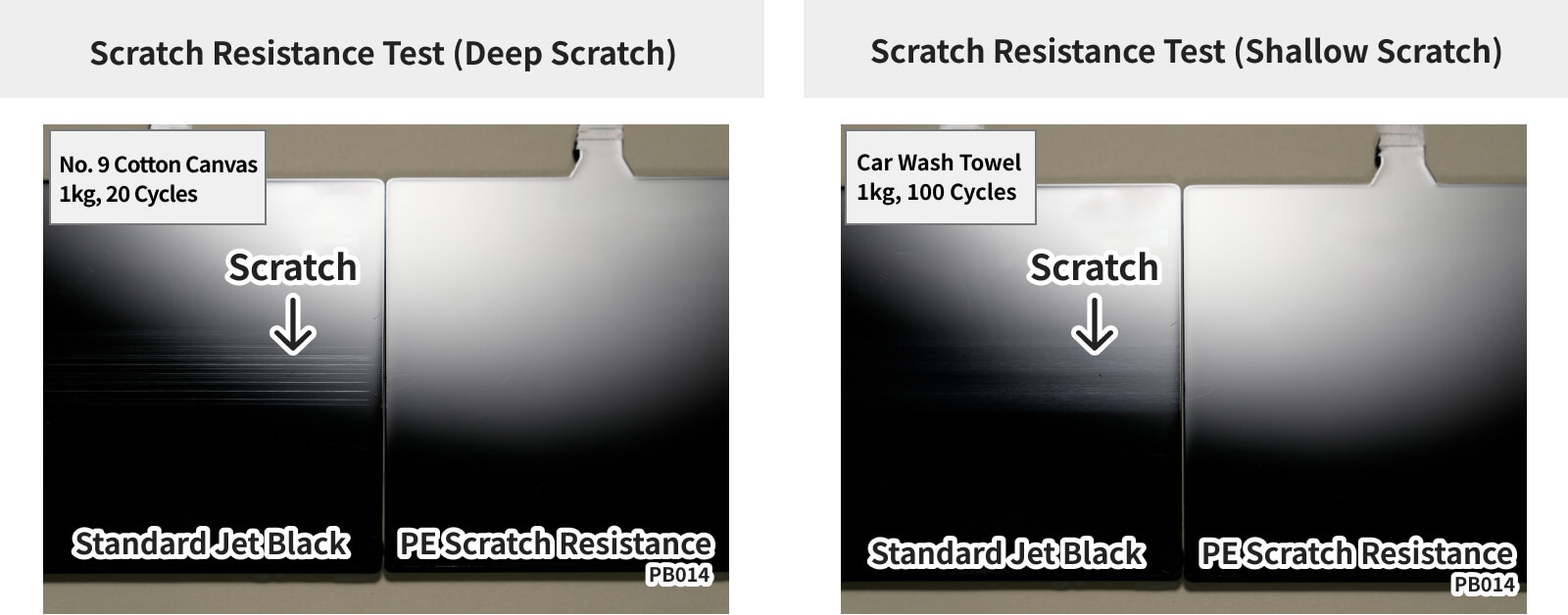

The DELPET™ Piano Black series has the same weather resistance as regular black acrylic, but is blacker than regular black. It also has a high gloss even without clear coating. We also offer products with excellent scratch resistance which will maintain a beautiful appearance for a long time.

PB/PB Scratch-Resistant series details

PB/PB Scratch-Resistant series features

Anyway, a luxurious black appearance is realized.

With high weather resistance, it maintains its appearance for a long time

Paintless design reduces environmental impact

Glossy finish with no need for clear coating

There are also grades with friction resistance.

Molding processability and mechanical strength equivalent to general acrylic

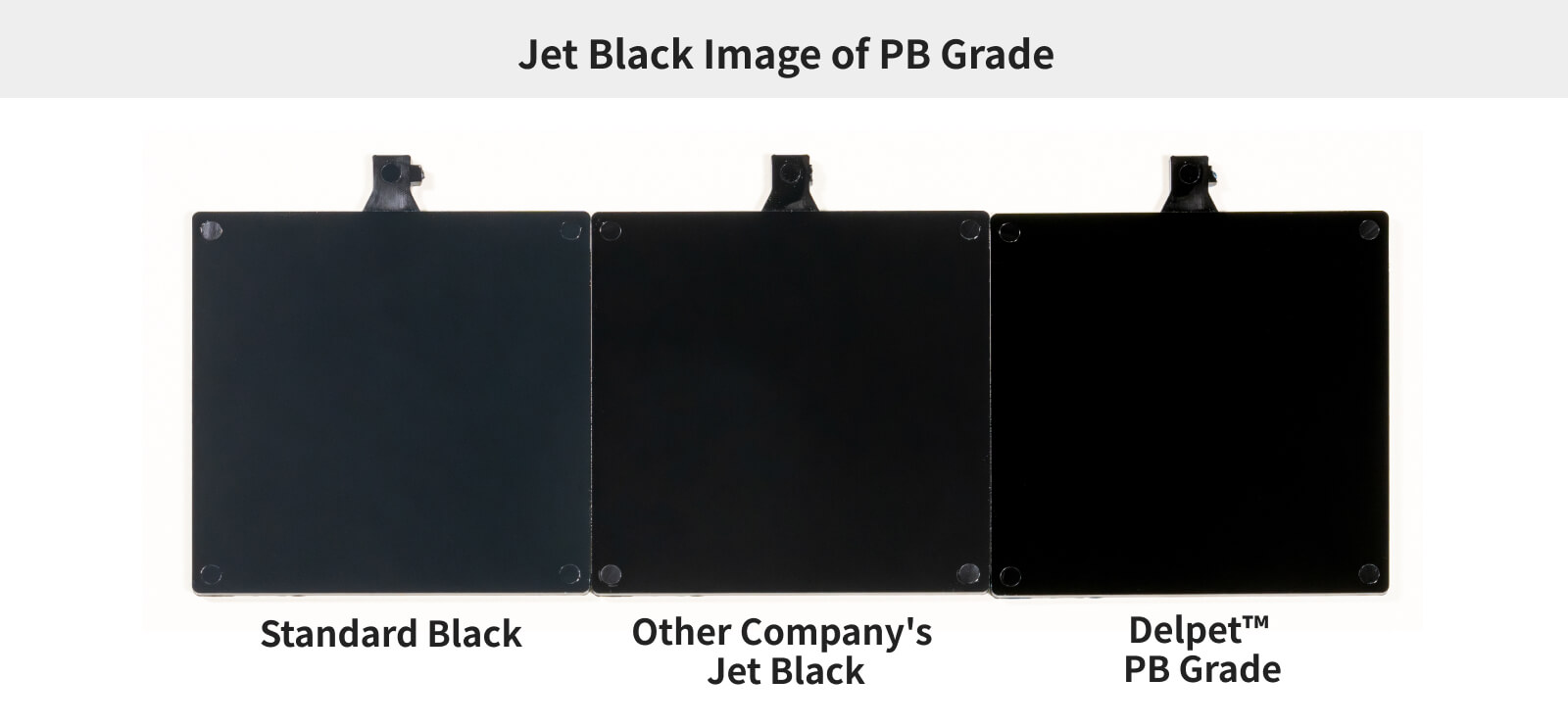

Image showing the jet black PB series

PB series Jet Black and Weather Resistance data

* The property value is a representative value and not a guaranteed value.

Scratch resistance test for PB series

Applications of the PB/PB Scratch-Resistant series

Automobile exteriors (tail light rims, pillars, rear garnish, etc.)

Home appliances

Automobile interiors

Musical instruments

Physical Properties of PB series

* The property value is a representative value and not a guaranteed value.

| Physical property items | Test method | Unit | General Grade | Bimodal grade | |||

| PB01 | PB21 | PB22 | PB23 | ||||

| Heat resistance | High fluidity | Solvent resistance | Good fluidity, solvent resistant | ||||

| 1. Flow characteristics | Melt flow-rate (230°C、37.3N) |

1133 | g/10min | 2 | 1.8 | 0.6 | 1.0 |

| Spiral length/wall thickness: 2mm, resin temperature: 250°C, mold temperature: 60°C, resin pressure: 75MPa | Asahi Kasei PMMA method | cm | 27 | 33 | 27 | 30 | |

| 2. Mechanical Properties | Tensile modulus | 527-1/1A/1 | MPa | 3300 | 3300 | 3300 | 3300 |

| Tensile breaking stress | 527-1/1A/5 | MPa | 77 | 77 | 77 | 77 | |

| Tensile failure strain | 527-1/1A/5 | % | 6 | 5 | 7 | 6 | |

| Bending elastic modulus | 178 | MPa | 3300 | 3300 | 3300 | 3300 | |

| Bending strength | 178 | MPa | 130 | 130 | 130 | 130 | |

| Charpy impact strength without notch | 179/1eU | kJ/m2 | 22 | 22 | 24 | 24 | |

| Charpy impact strength notched | 179/1eA | kJ/m2 | 1.4 | 1.3 | 1.4 | 1.4 | |

| 3. Thermal Properties | Deflection temperature under load(1.8MPa) | 75-1,2 | °C | 100 | 100 | 98 | 98 |

| Vicat softening temperature | 306B50 | °C | 108 | 108 | 106 | 106 | |

| 4. Other Properties | Lightness L* | SCE-based spectrophotometry (light source: D65/10 degree field) | - | <1.0 | <1.0 | <1.0 | <1.0 |

| Chromaticity a*/b* | - | -0.3/-1.3 | -0.3/-1.3 | -0.3/-1.3 | -0.3/-1.3 | ||

| Water absorption (23°C、24hr) | 62method1 | % | 0.3 | 0.3 | 0.3 | 0.3 | |

| Density | 1183 | g/cm3 | 1.19 | 1.19 | 1.19 | 1.19 | |

| Rockwell hardness M scale | 2039-2 | - | 100 | 100 | 95 | 98 | |

| Mold shrinkage | Asahi Kasei PMMA method | % | 0.2~0.6 | 0.2~0.6 | 0.2~0.6 | 0.2~0.6 | |

PB Scratch-Resistant series physical properties

* The property value is a representative value and not a guaranteed value.

| Physical property items | Test method | Unit | General Grade | Bimodal | |||

| PB014 | PB013 | PB033 | PB233 | ||||

| Resistant to fabric scratch | Heat resistance | Good fluidity and heat resistance | Good fluidity and heat resistance | ||||

| 1. Flow characteristics | Melt flow-rate (230°C、37.3N) |

1133 | g/10min | 3.1 | 2.0 | 6.0 | 1.0 |

| Spiral length/wall thickness: 2mm, resin temperature: 250°C, mold temperature: 60°C, resin pressure: 75MPa | Asahi Kasei PMMA method | cm | 31 | 27 | 34 | 30 | |

| 2. Mechanical Properties | Tensile modulus | 527-1/1A/1 | MPa | ー | 3300 | 3300 | 3300 |

| Tensile breaking stress | 527-1/1A/5 | MPa | 75 | 77 | 75 | 77 | |

| Tensile failure strain | 527-1/1A/5 | % | 5 | 6 | 5 | 6 | |

| Bending elastic modulus | 178 | MPa | 3020 | 3300 | 3300 | 3300 | |

| Bending strength | 178 | MPa | 116 | 130 | 120 | 130 | |

| Charpy impact strength without notch | 179/1eU | kJ/m2 | 20 | 21 | 19 | 22 | |

| Charpy impact strength notched | 179/1eA | kJ/m2 | 1.3 | 1.2 | 1.2 | 1.2 | |

| 3. Thermal Properties | Deflection temperature under load(1.8MPa) | 75-1,2 | °C | 94 | 100 | 100 | 98 |

| Vicat softening temperature | 306B50 | °C | 104 | 109 | 109 | 107 | |

| 4. Other Properties | Lightness L* | SCE-based spectrophotometry (light source: D65/10 degree field) | - | 0.4 | <1.0 | <1.0 | <1.0 |

| Chromaticity a*/b* | - | 0.1/-0.3 | 0.1/-0.4 | 0.1/-0.4 | 0.1/-0.4 | ||

| Water absorption (23°C、24hr) | 62 method1 | % | ー | 0.3 | 0.3 | 0.3 | |

| Density | 1183 | g/cm3 | 1.19 | 1.19 | 1.19 | 1.19 | |

| Rockwell hardness M scale | 2039-2 | - | ー | 100 | 98 | 98 | |

| Mold shrinkage | Asahi Kasei PMMA method | % | 0.2~0.6 | 0.2~0.6 | 0.2~0.6 | 0.2~0.6 | |