Plastic Reduction with

Bio-Fillers

As part of environmental initiatives, efforts to reduce plastic usage by highly filling with bio-fillers are gaining attention. While bio-filler compounds generally face challenges in terms of bending and impact resistance, Asahi Kasei's TUFTEC™ can be used as a compatibilizer to produce flexible compounded products. It is also expected to be effective in compatibilizing wood powder, starch, bamboo flour, and paper pulp.

TUFTEC™ for Compatibilizing Bio-Fillers with Plastics

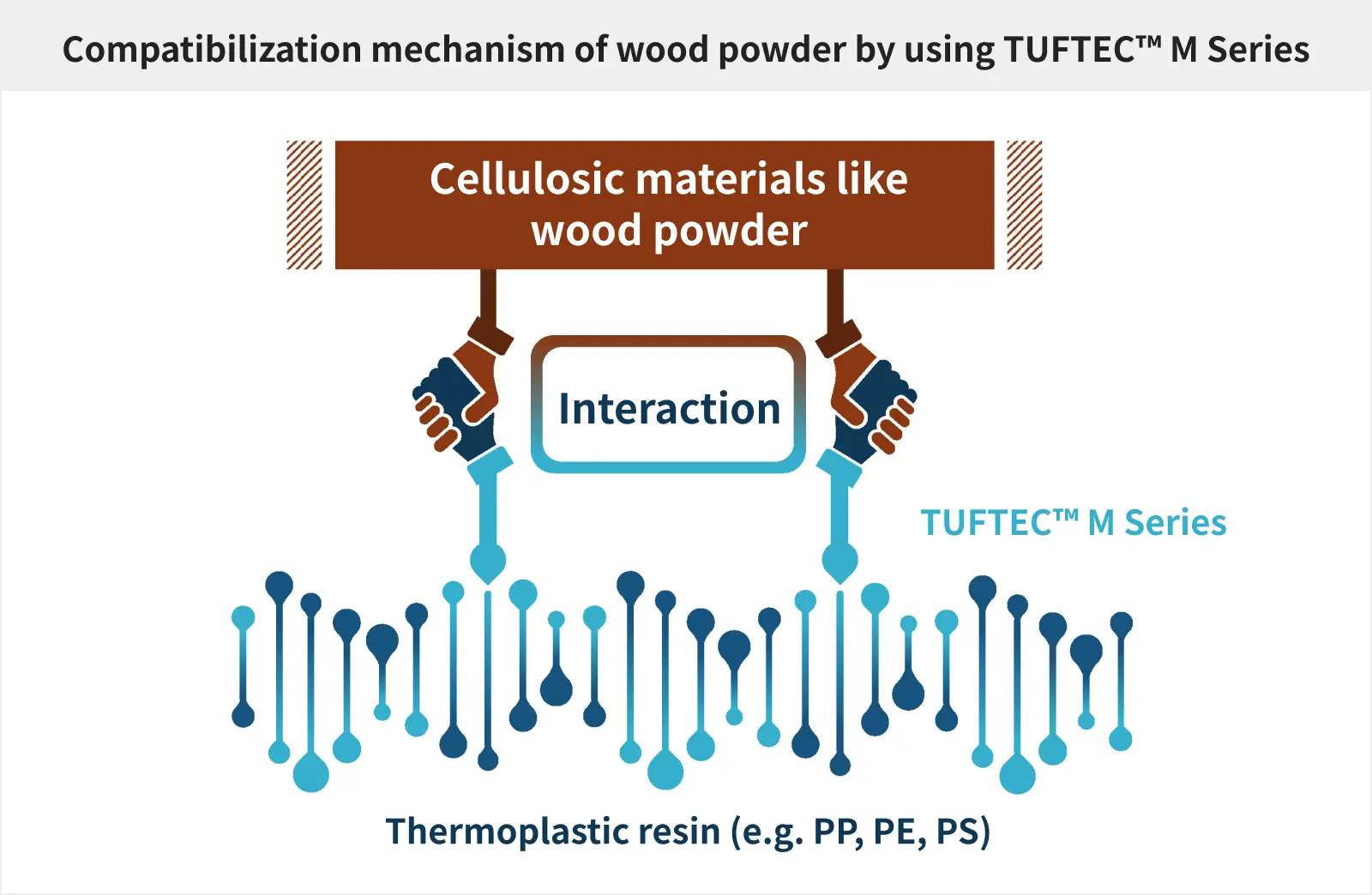

Wood powder typically undergoes a change in properties at temperatures exceeding 230°C, making it suitable for use as a compounding raw material only with olefin-based or styrenic plastics having a melting point below 200°C. However, due to the high polarity of wood powder and the hydrophobic nature of plastics, these two materials are incompatible and difficult to mix.

TUFTEC™︎ M series is the optimal solution to this challenge. The acid-modified portion of TUFTEC™ interacts with the polar groups on the surface of wood powder, enhancing the affinity between wood powder and plastic and enabling mixing.

Significantly Improving the Performance of Bio-Filler Compounds

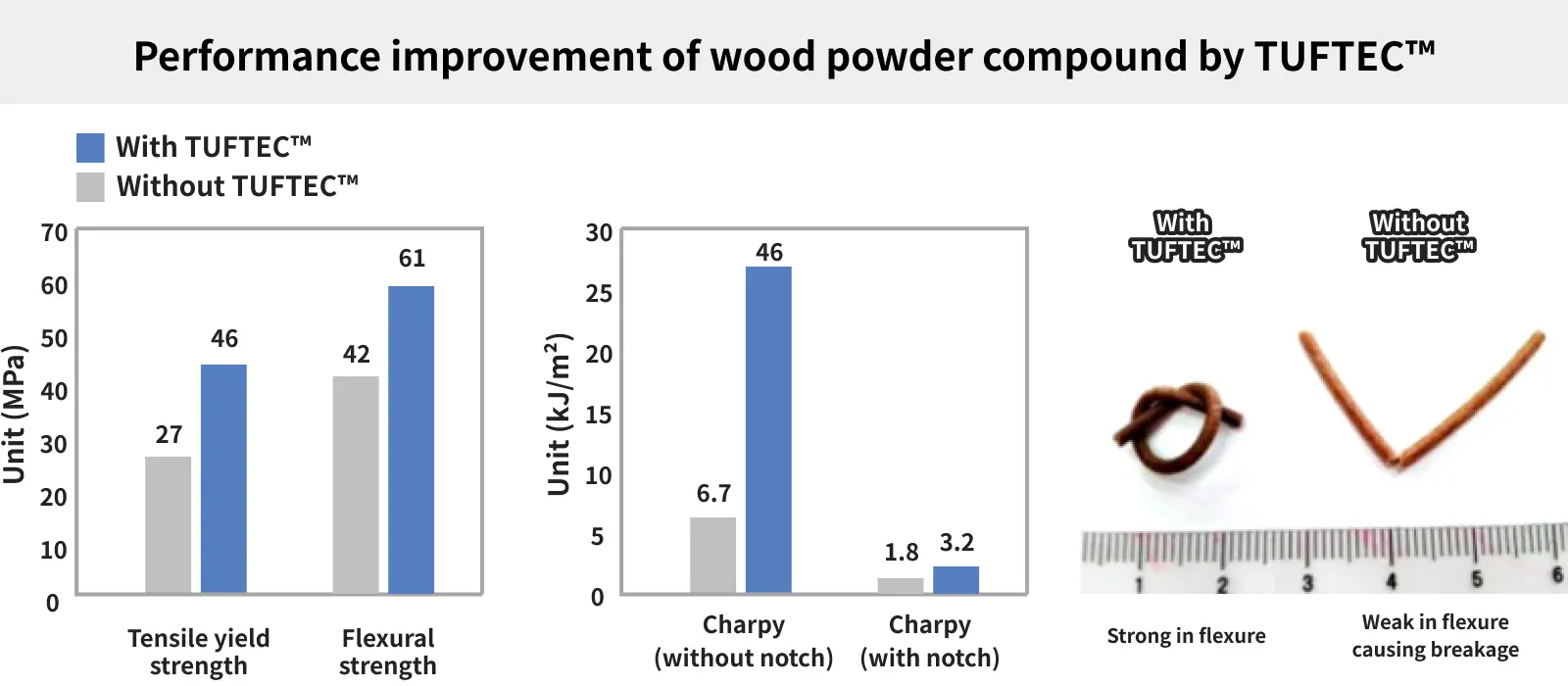

Previously, bio-filler compounds suffered from weaknesses in bending and impact resistance, making them impractical for use as material in products.

TUFTEC™ M series exhibits affinity with both bio-fillers and plastics. When added as a compatibilizer, it significantly enhances the impact resistance of the compound, imparts toughness, and improves flexibility and ductility. This enables the application of the material in a wide range of products.

Offering Proposals for Various Applications

Bio-filler compounds using TUFTEC™ as a compatibilizer exhibit excellent toughness and are suitable for various product applications. We offer proposals for diverse applications, including food containers, furniture and home appliances, and mobility.

These resin products utilizing bio-fillers effectively communicate your commitment to environmental responsibility. If you are interested in environmental solutions and reducing plastic usage, please do not hesitate to contact us.