Solving the Challenges of Material Recycling

Material recycling typically faces challenges such as "degradation of resin" due to long-term use and thermal history and a decline in physical properties due to "mixing of different resins" that cannot be sorted out. TUFTEC™ can improve the physical properties of recycled resins as a modifier and compatibilizer.

TUFTEC™ Realizes Upcycling of Recycled Materials

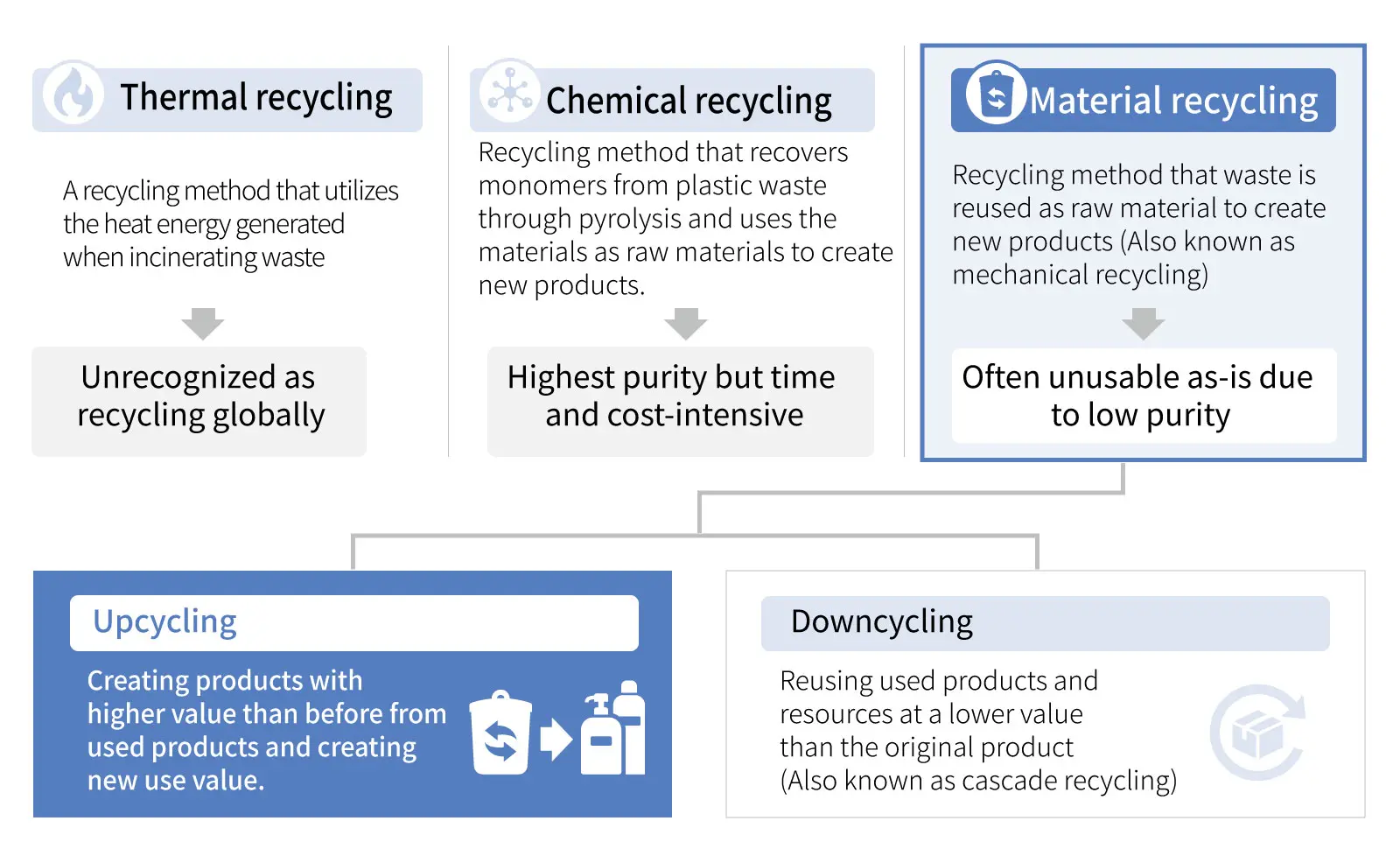

While plastics are widely used in society, their non-biodegradability poses a significant environmental burden and makes their sustainable use a major challenge.

As a solution, various plastic recycling methods are being considered, as shown in the diagram below. Asahi Kasei focuses on "material recycling," which reuses discarded plastics as raw materials. While it is generally difficult to achieve the required purity and maintain the physical properties of recycled plastics, TUFTEC™ can be used as a modifier and compatibilizer to improve physical properties, thereby enhancing the value of recycled resin and allowing for its reuse.

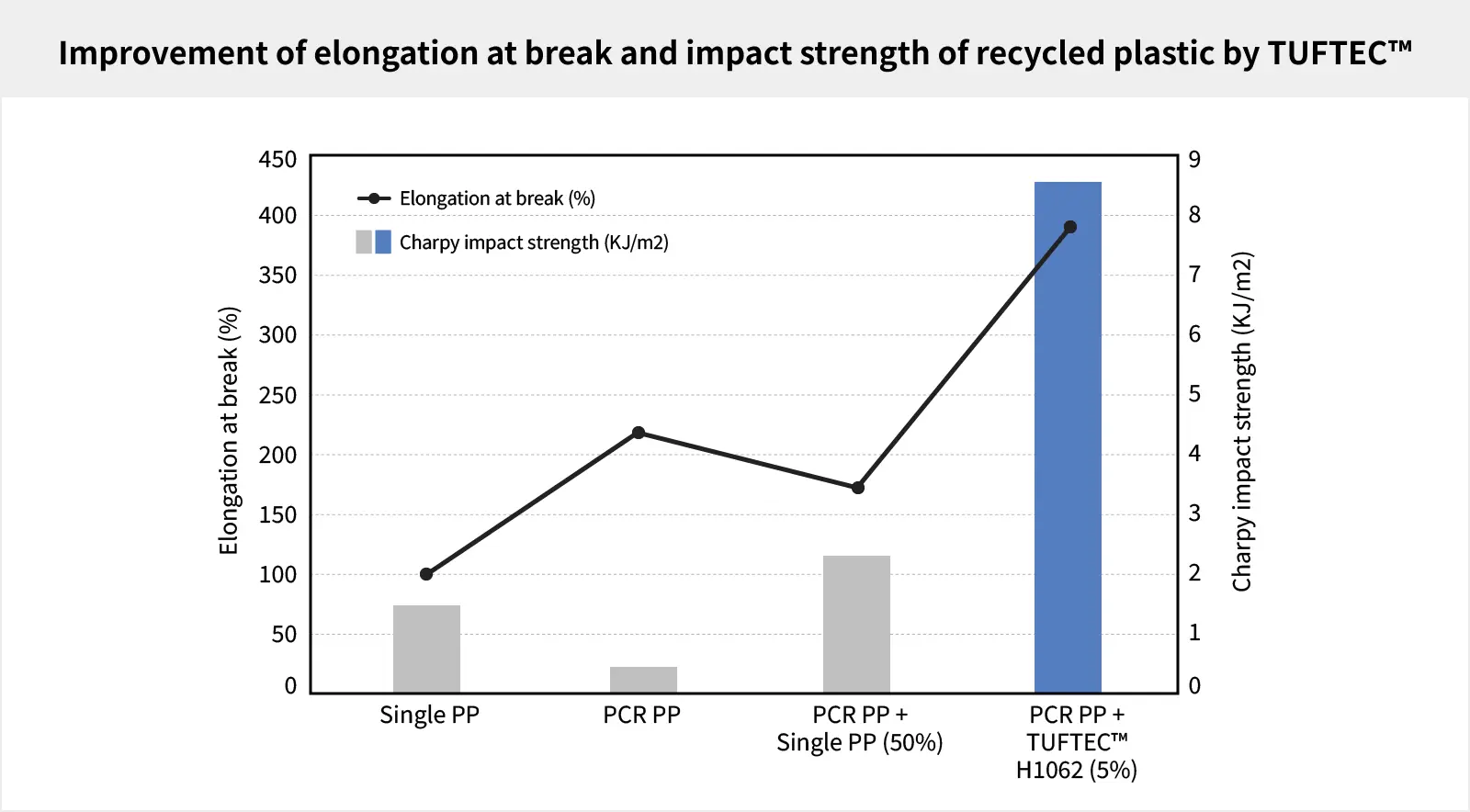

Dramatically Improves Physical Properties of Recycled Resin as a Modifier

Plastics undergo various side reactions, such as partial cross-linking or degradation, due to heat and light. In the recycling process, used resins are subjected to more heat than usual, resulting in more pronounced occurrences of the aforementioned phenomena. This causes a significant deterioration of material properties compared to virgin resin.

TUFTEC™ can improve flexibility and impact resistance as a modifier for PP, PE, PS, and other engineering plastics. Therefore, by adding a small amount, just a few percent, it is possible to significantly improve the mechanical properties of recycled resin, such as its reduced impact strength and elongation.

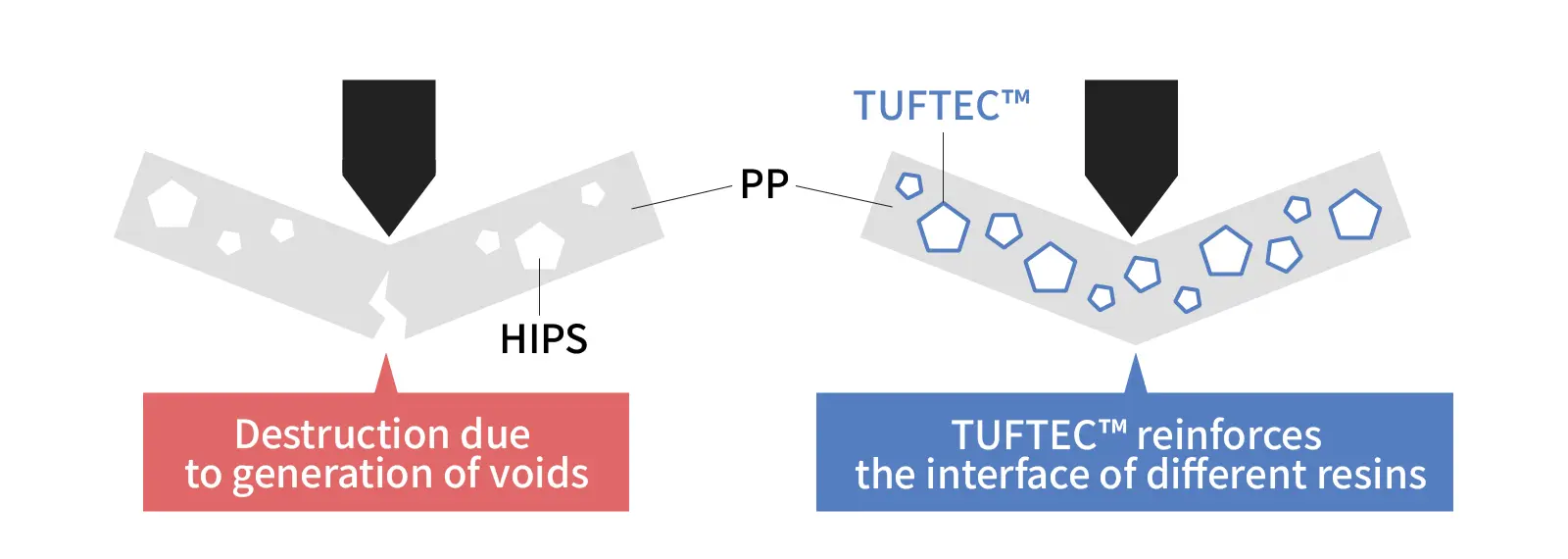

Enhancing Physical Properties of Mixed Plastics as a Compatibilizer

In material recycling, collected resins are sorted for use, but no matter how carefully they are sorted, mixed plastics cannot be completely avoided, and the mixing of different resins can cause a deterioration in physical properties.

Asahi Kasei's TUFTEC™ is compatible with styrenic and olefinic resins, enabling compatibilization of different resins, such as PP and PS. Moreover, Asahi Kasei offers grades that react with highly polar resins and fillers, allowing for compatibilization of complex mixed plastics, such as PP and PET or PA engineering plastics, and the improvement of their physical properties.

By leveraging this characteristic, it is possible to improve the mechanical properties of recycled resin, prevent cracking from the interface, and improve the appearance of recycled plastics caused by the mixing of different resins.

See the page "Select products based on compatibilizer usage"

Offering Various Applications, Including Automotive, Appliances, and Food and Living

Asahi Kasei offers a wide range of applications for recycled materials with improved physical properties through TUFTEC™, including automotive, appliances, and food and living products. If you are interested in manufacturing that incorporates environmental considerations and eliminates waste to improve productivity, please do not hesitate to contact us.