TUFTEC™ Increases the

Biomass Ratio of Styrene-based Resins

Asahi Kasei's TUFTEC™ acts as a compatibilizer, enabling the blending of bio-polyethylene (PE) and other biomass plastics into styrene-based resins. This allows for increased biomass ratios in resin compositions without compromising impact resistance and other mechanical properties.

Balancing Mechanical Properties and Biomass Ratio in Styrene-based Resins

The movement toward a sustainable future is prompting the shift away from petroleum-based plastic raw materials to plant-derived or chemically recycled renewable raw materials.

However, resins like ABS and PS rely on styrene, an aromatic compound, as a primary raw material. While plant-derived aromatic compounds exist, they are non-uniform and difficult to isolate as styrene monomers, making it challenging to replace conventional raw materials with plant-based alternatives. Chemical recycling, while yielding high-purity styrene monomers, faces challenges in securing a stable supply of recycled materials.

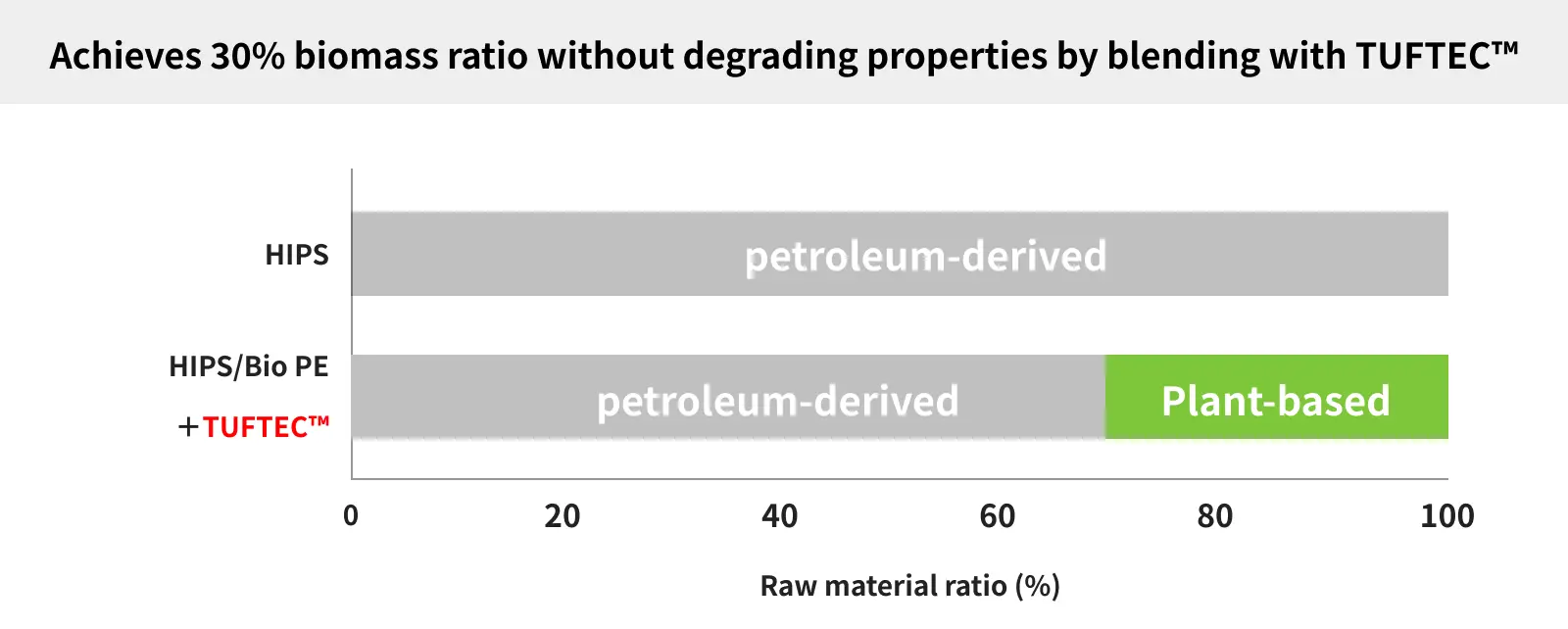

Asahi Kasei's TUFTEC™ acts as a compatibilizer, allowing for the alloying of styrene-based resins with bio-polyethylene (PE), increasing the biomass ratio of the resin composition without sacrificing mechanical properties.

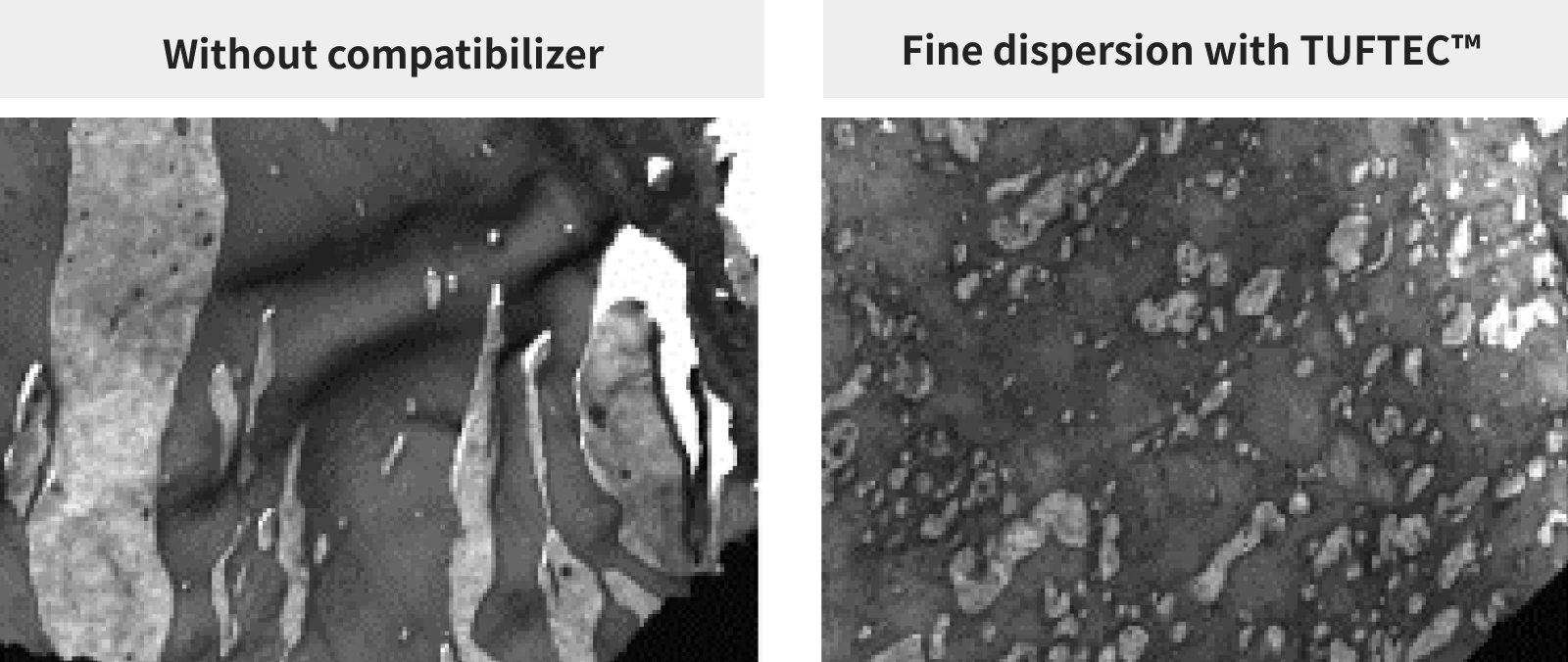

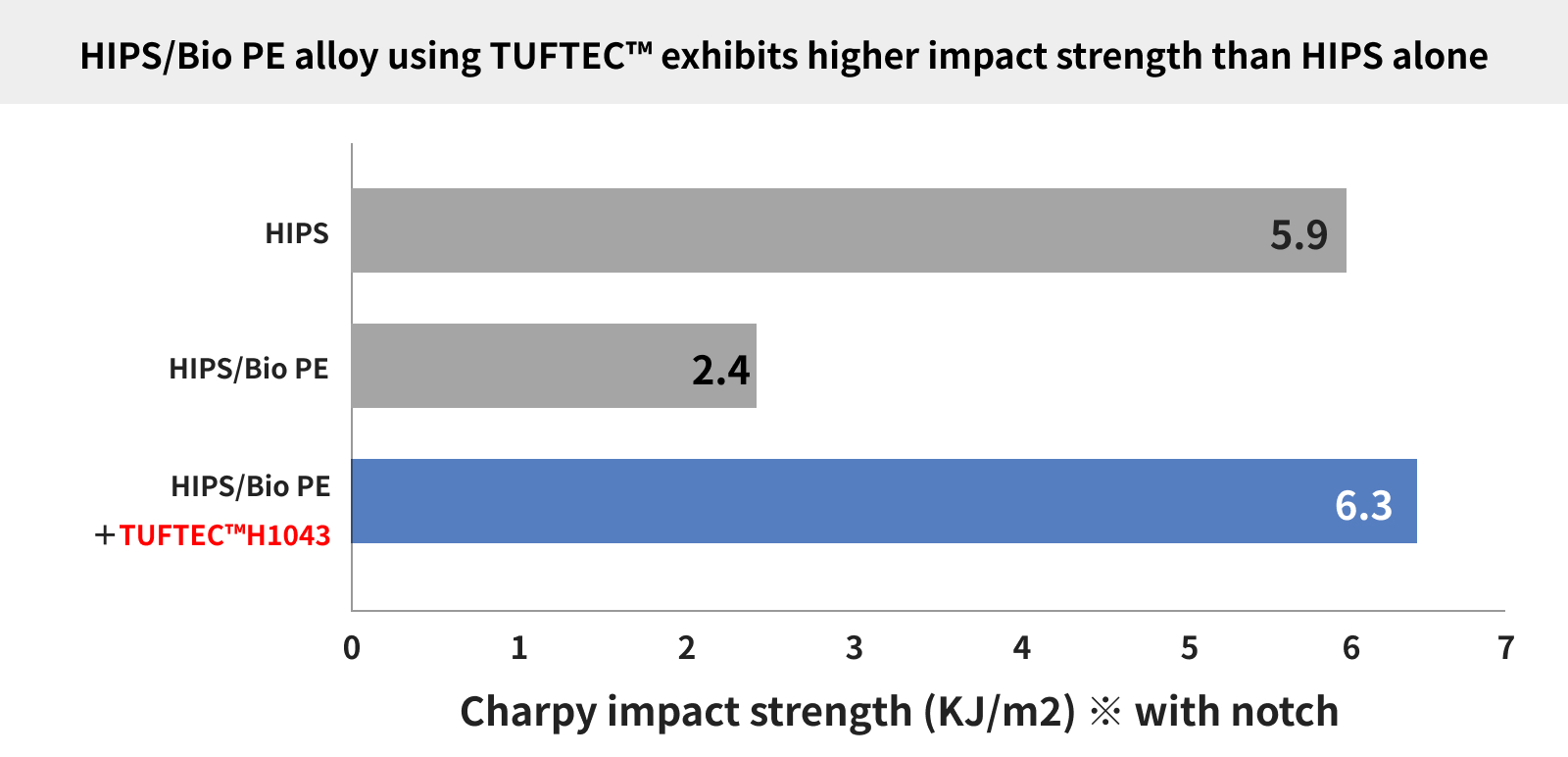

For example, HIPS and bio-PE are incompatible, and without a compatibilizer, alloying results in weak interfaces and delamination, significantly reducing impact resistance and other mechanical properties. However, incorporating TUFTEC™ H1043 as a compatibilizer allows for the fine dispersion of bio-PE within the HIPS matrix, enhancing interfacial strength and significantly improving mechanical properties. Blending in bio-PE also increases the biomass ratio of the resin compound.

Achieving Increased Biomass Ratios without Sacrificing Properties

Generally, alloying incompatible materials like styrene-based resins and biomass plastics without a compatibilizer results in significant degradation of mechanical properties. Using TUFTEC™ as a compatibilizer enables the incorporation of approximately 30 wt.% bio-PE into HIPS without compromising mechanical properties.

Learn more about “Asahi Kasei’s Commitment to Sustainability”