Challenges and Solutions to Polyolefin Adhesion

Polyolefins—specifically polyethylene (PE) and polypropylene (PP)—are notoriously difficult resins to bond. This article details the underlying reasons for their poor adhesion, outlines effective bonding techniques, and introduces Asahi Kasei’s elastomer products that enable reliable bonding between PE/PP and a wide range of dissimilar materials.

Reasons Why Polyethylene and Polypropylene are Difficult to Bond

Polyolefins (polyethylene/polypropylene, hereinafter PE/PP) have a non-polar structure without functional groups. For an adhesive to bond firmly with a material, it needs functional groups (polarity) that act as "hands" to attract each other. However, because polyolefins lack these functional groups, it is difficult to obtain sufficient adhesive strength with common polar adhesives.

Main Methods to Enable Polyolefin (PE/PP) Adhesion

There are several approaches to achieve dissimilar material adhesion, including polyolefins. Here, we will introduce three representative methods.

-

Applying a Primer TreatmentA primer is a material with functional groups that induce interactions between the adherend (bonding target) and the adhesive. Applying a primer to the surface of a polyolefin creates an environment where both the material and the adhesive can easily interact each other, leading to the improvement in the adhesive strength. However, if the selection of primer is unsuitable, sufficient adhesive strength may not be obtained. In addition, selecting a suitable primer and process design are also important because attention must be paid to time management and work procedures after applying the primer.

-

Performing Plasma TreatmentPlasma treatment is a method that uses plasma generated from gas to remove oils and dirt from the material surface, while simultaneously generating functional groups and increasing the surface energy. Polyolefins that have undergone plasma treatment tend to become polarized, making this a popular method for obtaining high adhesion while being environmentally conscious. However, the introduction of plasma treatment equipment requires a certain amount of capital investment, and attention must be paid to time management and storage environment in the bonding process after treatment, so there are hurdles in terms of cost and operation at the time of introduction.

-

Utilizing the Anchor EffectThe anchor effect is to increase adhesive strength by physically or chemically roughening the surface of the adherend so that the adhesive "catches" on it. By performing sandblasting or chemical etching, stable adhesive strength can be obtained with a relatively simple mechanical method. However, if the surface is roughened too much, the material itself may be damaged, and sufficient effects may not be obtained depending on the material, so it is necessary to determine appropriate processing conditions.

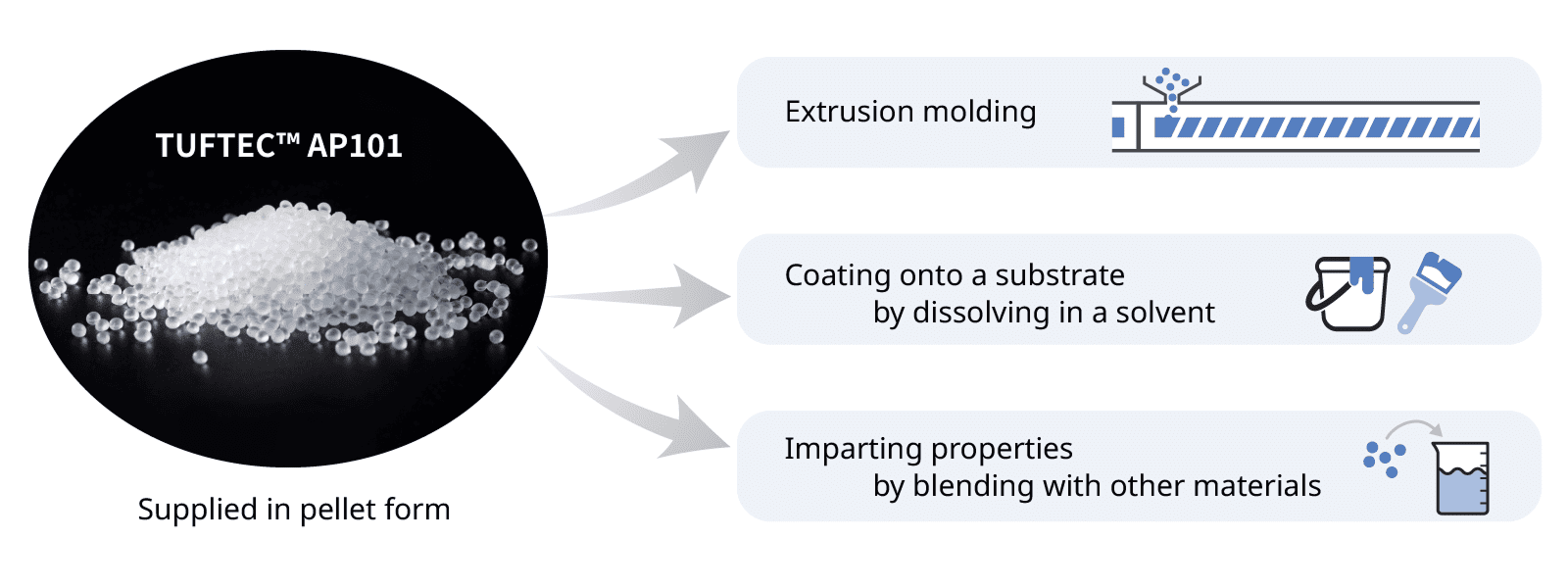

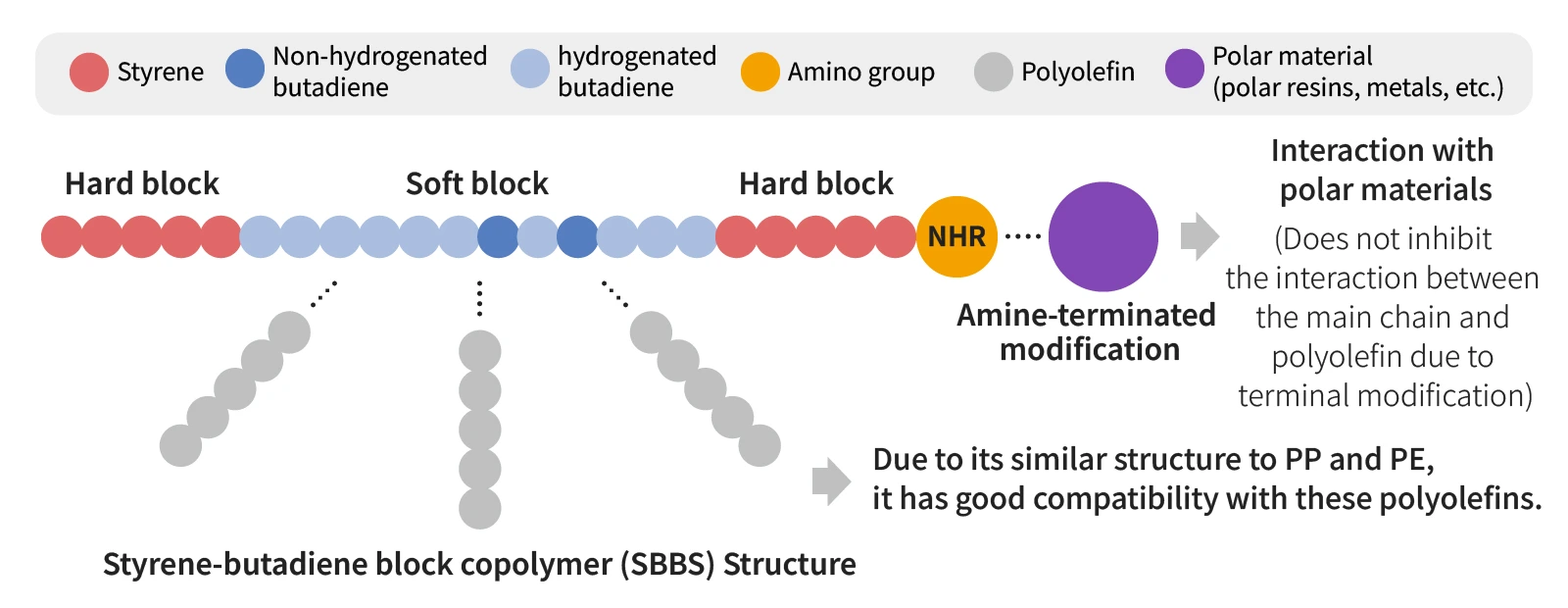

Dissimilar Material Adhesion Solutions Utilizing TUFTEC™ AP101 with Amine-Modification of Asahi Kasei’s Unique Technology

TUFTEC™ AP101 is an amine-modified styrenic thermoplastic elastomer, which has amino groups with affinity for various polar materials such as polar resins and metals at the polymer chain ends, while also having a soft block main chain structure with high affinity for polyolefins. Since the amino groups are located at the polymer chain ends, they can interaction with polar materials without impairing the affinity between the soft block main chain and the polyolefin.

If you want to bond polyolefins and polar materials, we recommend considering a design that utilizes TUFTEC™ AP101.