New Grade Achieves ESCR HIPS with Excellent Oil Resistance

Asahi Kasei's synthetic rubber, with its new grade featuring a high styrene solution viscosity (SV), enables the production of ESCR HIPS with excellent oil resistance by increasing the rubber particle size. Manufactured through solution polymerization, it boasts high quality and minimized impurities. Moreover, it achieves improved heat stability and reduced gelation.

New Grade with High Styrene Solution Viscosity Dedicated to ESCR HIPS

Conventional HIPS has poor oil resistance. When used in environments exposed to oil (butter, margarine, vegetable oil, etc.), such as refrigerator interiors (walls and bottoms), it deteriorates. Deterioration can lead to reduced strength, potentially causing cracks and damage.

Asahi Kasei has developed a new grade with a high styrene solution viscosity. By increasing the rubber particle size in HIPS, it achieves the production of ESCR HIPS with high oil resistance.

Offering High-Quality Products with Minimal Impurities and Gel

Generally, the quality of synthetic rubber is influenced by the presence or absence of impurities and gel. Impurities can trigger unexpected reactions, leading to instability in physical properties or discoloration. Gel, on the other hand, can hinder achieving the desired physical properties and result in issues like poor appearance.

Asahi Kasei's low-cis polybutadiene rubber used in ESCR HIPS applications is manufactured through solution polymerization. This process results in a high-quality product that is colorless, has minimal impurities, and contains extremely low levels of gel insoluble in styrene. These features help prevent issues related to physical properties, appearance, and more.

Additionally, it offers excellent cold flow resistance, ensuring the long-term maintenance of bale shape.

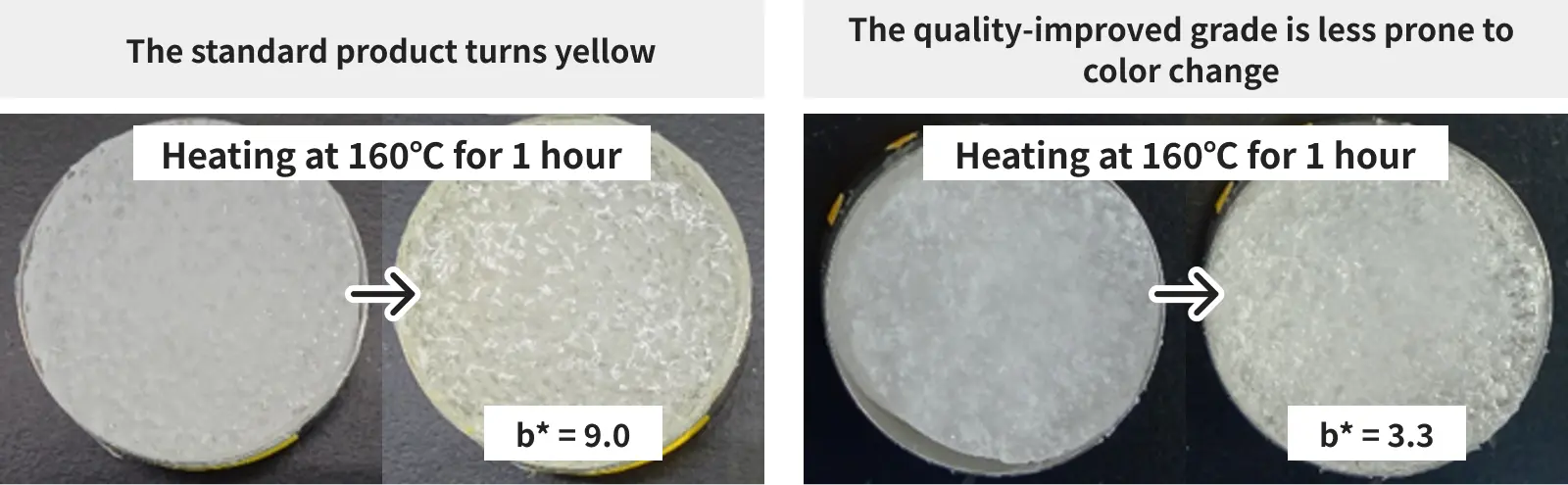

Achieving "Improved Heat Stability and Reduced Gelation" for Enhanced Productivity

Synthetic rubber is generally heat-sensitive. Prolonged exposure to heat during storage, transportation, or cutting can potentially lead to color changes or gelation.

The new grade utilized in ESCR HIPS achieves improved heat stability and reduced gelation through adjustments in polymer design and manufacturing processes. This contributes to enhanced productivity by improving yield and reducing losses in customers' production processes.

Contact Us for More Information

We are happy to propose the most suitable grades and provide samples based on your specific needs. Please feel free to contact us if you are interested in ESCR HIPS applications.