Balancing Impact Resistance and Gloss in HIPS

Asahi Kasei's synthetic rubbers are widely used in HIPS applications. We offer a wide range of grades with different styrene solution viscosities (SV), providing you with the optimal grade to balance impact resistance and gloss in HIPS to the level you require. Another characteristic of Asahi Kasei's synthetic rubbers is their low impurities and suppression of gelation. We also offer grades with "improved heat stability and gelation suppression."

Asahi Kasei's Synthetic Rubbers are Widely Used in HIPS Applications

Polystyrene (PS) is a hard and brittle material by itself. This means that PS moldings are susceptible to cracking when subjected to impact. Asahi Kasei's synthetic rubbers have a long history of being used as raw materials for HIPS (High Impact Polystyrene), which improves the impact resistance of PS. They are widely used in various applications, including food containers.

Achieving a Balance of Impact Resistance and Gloss in HIPS

When rubber is polymerized into polystyrene (PS) to produce HIPS, impact resistance and gloss depend on the particle size of the precipitated rubber. Larger particle sizes improve impact resistance but reduce gloss. On the other hand, smaller particle sizes increase gloss but reduce impact resistance. A balance between impact resistance and gloss must be achieved depending on the application.

Asahi Kasei's synthetic rubbers are available in a wide range of grades with different styrene solution viscosities (SV). By selecting the appropriate grade, it is possible to control the particle size of the rubber in HIPS. This allows you to manufacture HIPS with a balanced impact resistance and gloss that meets your requirements.

We also offer "ultra-high gloss" grades that focus on gloss. If you are looking for HIPS with unprecedented gloss, please feel free to contact us.

Providing High-Quality Products with Very Low Impurities and Gel

Generally, the quality of synthetic rubber is affected by the presence or absence of impurities and gel. Impurities can cause unexpected reactions, leading to instability in physical properties or discoloration. Gel can also cause problems such as failure to achieve desired physical properties and poor appearance.

Asahi Kasei's Low-cis Polybutadiene Rubber and styrene butadiene rubber used in HIPS applications are produced by solution polymerization. Therefore, they are high-quality products that are colorless, low in impurities, and very low in gel that is insoluble in styrene, which can suppress the occurrence of problems such as physical properties and appearance.

They also have excellent cold flow resistance and can maintain the shape of the bale for a long time.

We Also Offer Grades That Can "Improve Heat Stability and Suppress Gelation"

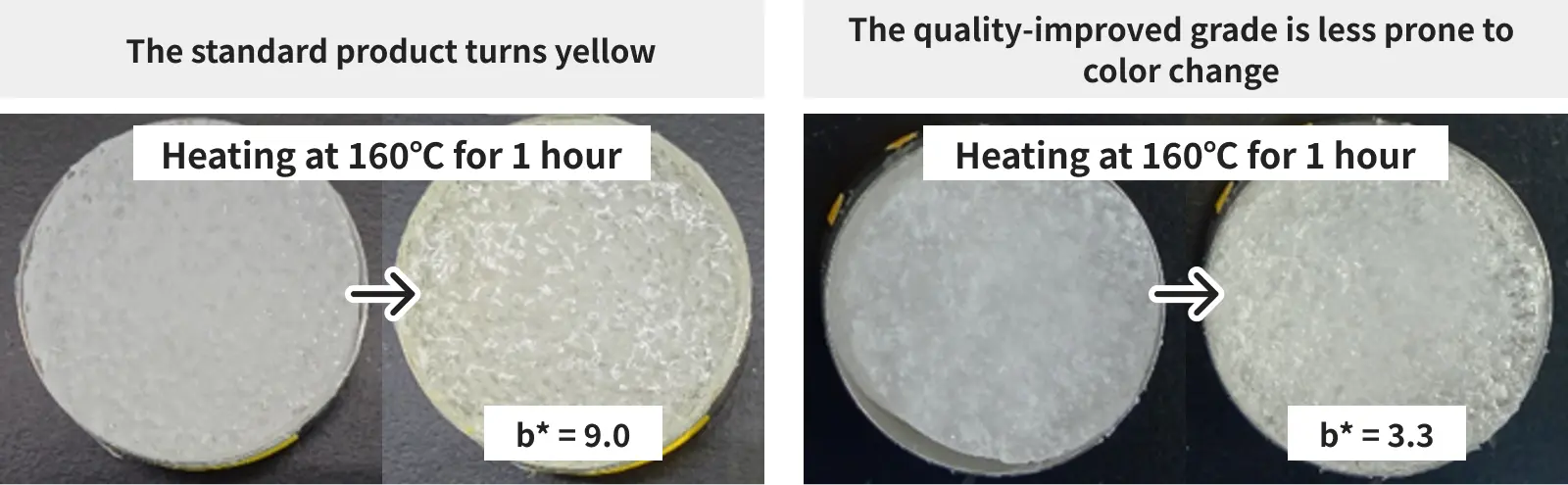

Synthetic rubbers are generally heat-sensitive, and may undergo color changes or gelation when subjected to prolonged heat, such as during storage, transportation, or cutting.

Asahi Kasei's polybutadiene rubbers L110 and L113, used in HIPS, have achieved improved heat stability and suppression of gelation by adjusting polymer design and manufacturing processes. This helps improve yield in your product manufacturing and contributes to increased productivity.

Feel Free to Contact Us

We are happy to offer you the optimal grade and provide samples to meet your specific needs. Please feel free to contact us if you are interested in HIPS applications.