Realizing High-Performance Transparent Outsoles

Conventional transparent outsole materials have a trade-off between abrasion resistance and grip. Asahi Kasei's ASAPRENE™ 306 has succeeded in improving abrasion resistance while maintaining grip through its unique polymer design. This allows for the realization of transparent outsoles that achieve both abrasion resistance and grip at a high level, which was previously difficult.

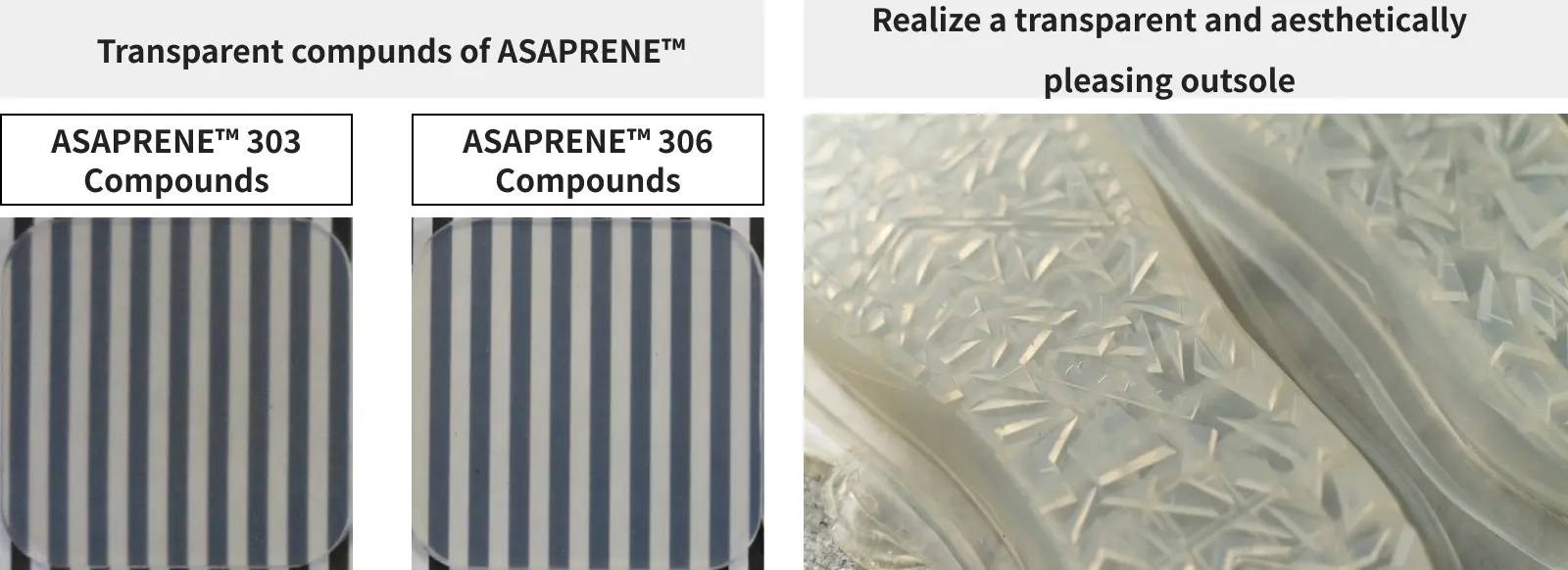

Manufacturing Highly Transparent Outsoles with ASAPRENE™ 303 and 306

When consumers choose shoes, functionality is of course important, but design is also a very important criterion. Asahi Kasei's SBR ASAPRENE™ 303 and 306 can be used to manufacture outsoles with high transparency by controlling the styrene ratio. This dramatically expands the range of expression in shoe design, allowing for more attractive products to be offered to consumers.

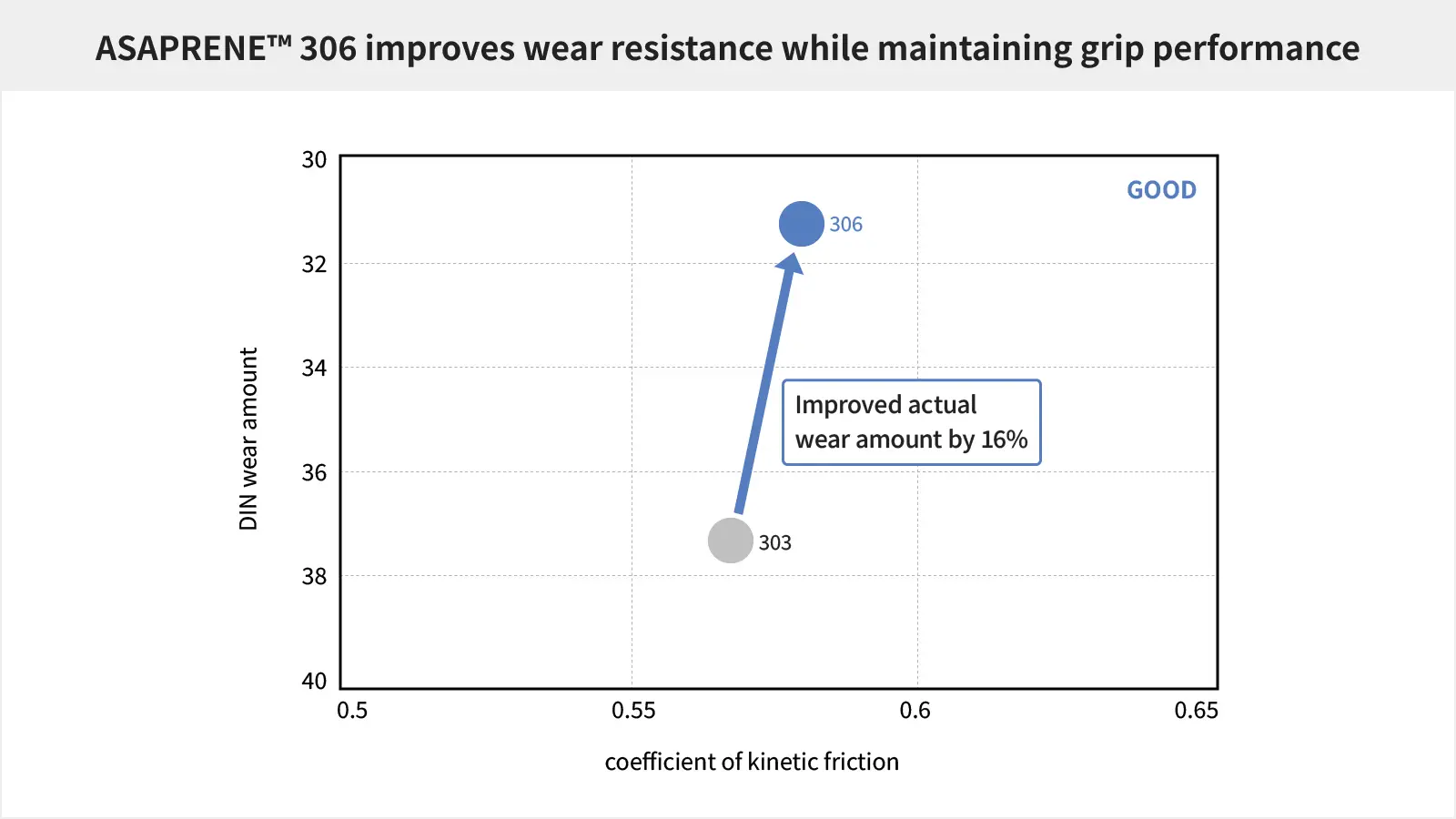

ASAPRENE™ 306 Achieves High Levels of Grip and Abrasion Resistance

Shoe outsoles require not only design, but also grip (traction) and abrasion resistance. Grip is the frictional force between the sole and the ground, and is related to the shoe's non-slip properties. Abrasion resistance is the resistance to wear and tear, which directly affects the shoe's durability.

However, there are limitations to the formulation for making outsoles transparent, which makes it difficult to increase grip and abrasion resistance. Furthermore, the grip and abrasion resistance of SBR both depend on Tg (glass transition temperature). Increasing Tg improves grip, but reduces abrasion resistance. Conversely, lowering Tg improves abrasion resistance, but reduces grip, resulting in a trade-off.

Asahi Kasei's SBR ASAPRENE™ 306 has succeeded in improving abrasion resistance while maintaining grip through its unique polymer design. This allows for transparent outsoles to achieve both grip and abrasion resistance.

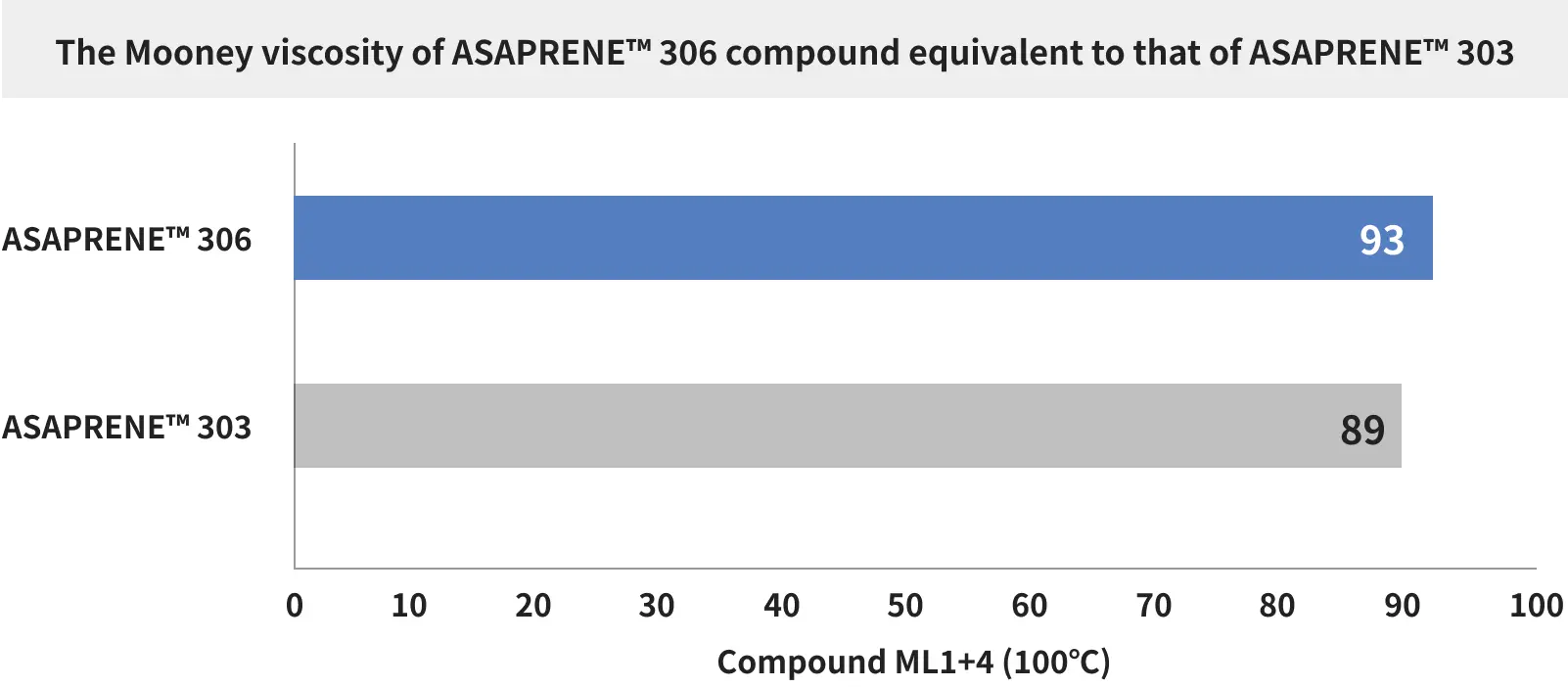

ASAPRENE™ 306 Also Offers Excellent Processability of the Formulation

Synthetic rubbers used in shoe outsoles require good processability during formulation to improve workability.

ASAPRENE™ 306 has a Mooney viscosity during formulation that is as good as the conventional 303 grade. Therefore, kneading (mixing) is not hindered.

Feel Free to Contact Us

We will offer you the optimal grade and provide samples based on your needs. Please feel free to contact us if you are interested in transparent outsole applications.