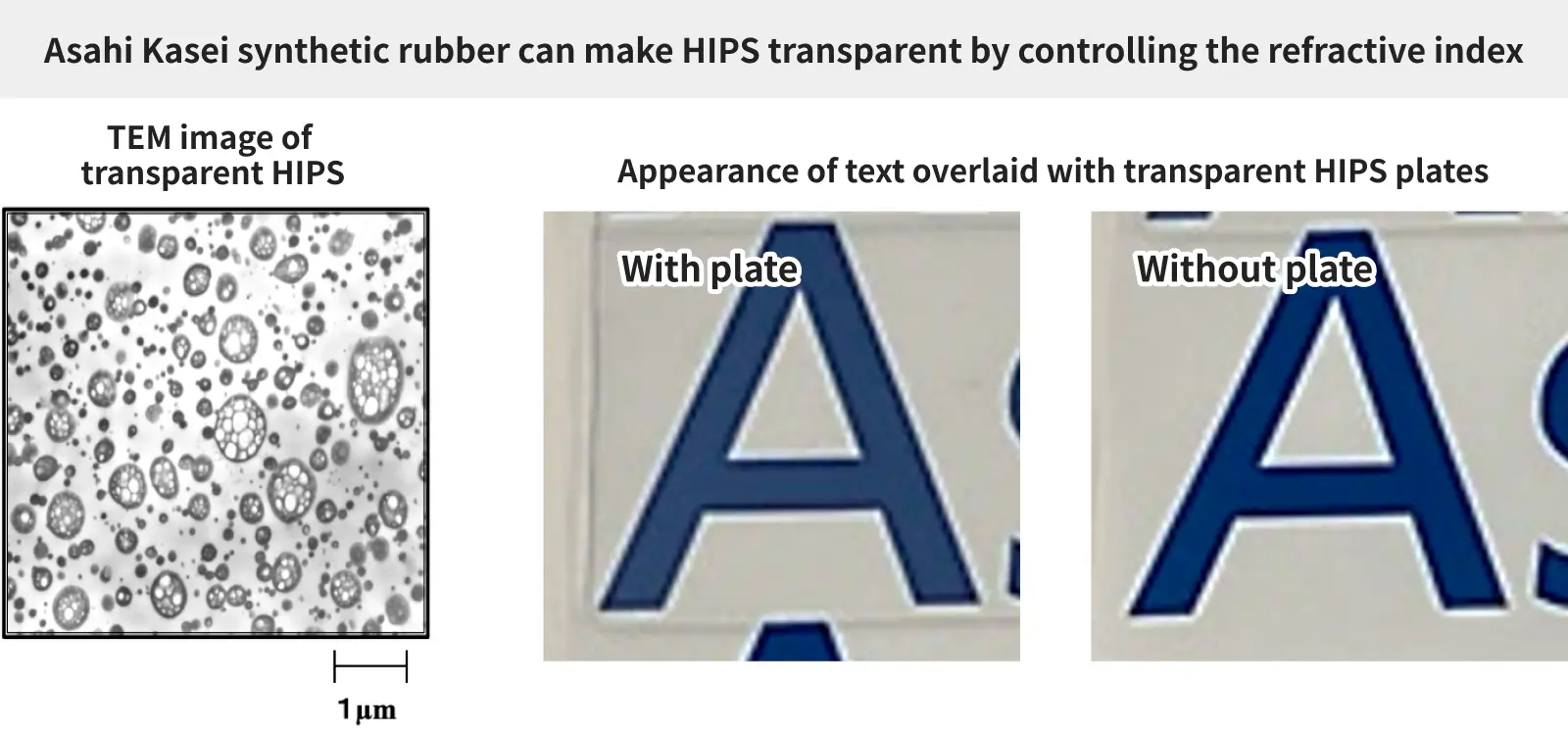

Enabling the Production of Highly Transparent HIPS

Asahi Kasei's synthetic rubber enables the production of transparent HIPS by controlling the refractive index. Produced through solution polymerization, it boasts high quality and minimized impurities. Furthermore, it achieves improved thermal stability and reduced gelation.

Asahi Kasei's Unique Polymer Structure Design Achieves "Transparent HIPS"

Polystyrene (PS) is inherently brittle, requiring the addition of synthetic rubber to enhance impact resistance. While PS exhibits high transparency, the addition of synthetic rubber in HIPS causes light scattering, resulting in a cloudy appearance.

Asahi Kasei's unique technology allows for refractive index control through polymer structure design. This ensures the refractive index matches that of styrene, methyl methacrylate (MMA), and butyl acrylate (BA) copolymers, which are the raw materials for transparent HIPS, enabling the production of transparent HIPS.

Providing High-Quality Products with Minimal Impurities and Gel

Generally, the quality of synthetic rubber is influenced by the presence of impurities and gel. Impurities can lead to unexpected reactions, causing instability in properties or discoloration. Gel, on the other hand, can hinder the achievement of desired properties and negatively impact the appearance.

Asahi Kasei's styrene butadiene rubber used for transparent HIPS applications is manufactured through solution polymerization. This results in a high-quality product that is colorless, low in impurities, and contains minimal gel insoluble in styrene, effectively mitigating issues related to properties and appearance.

Moreover, it exhibits excellent cold flow resistance, maintaining the shape of the bale for extended periods.

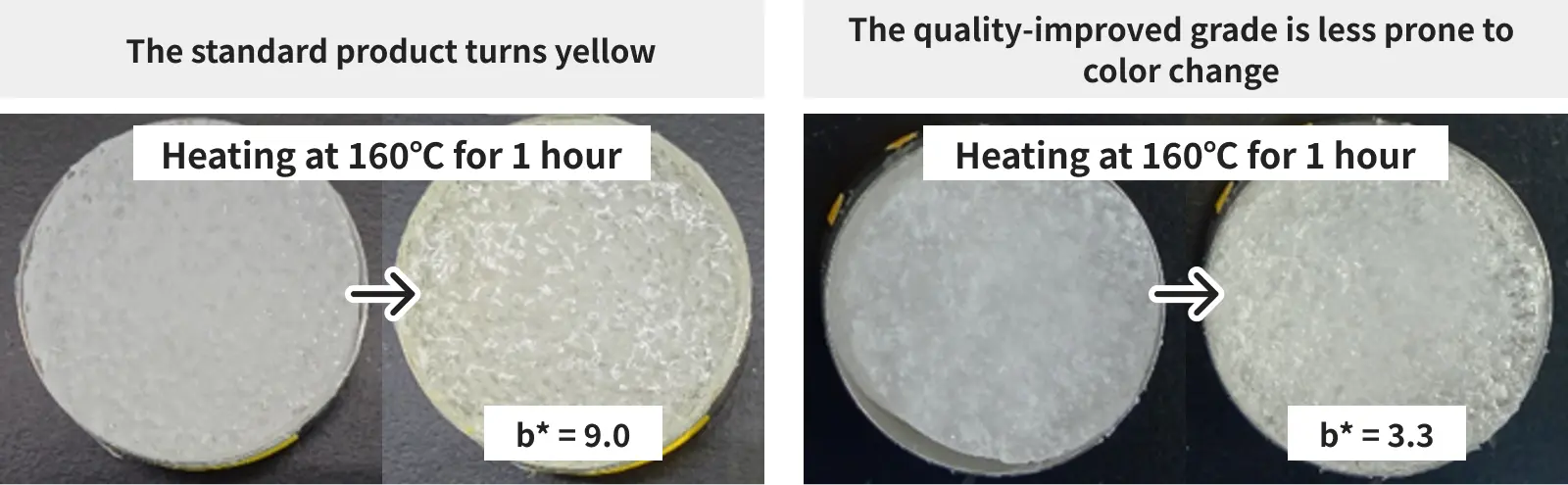

Achieving "Improved Thermal Stability and Gel Suppression" for Enhanced Productivity

Synthetic rubber is generally sensitive to heat. Prolonged exposure to heat during storage, transportation, or cutting can lead to discoloration or gelation.

Asahi Kasei's SBR used in transparent HIPS is designed with adjustments to polymer design and manufacturing processes, resulting in improved thermal stability and gel suppression. This contributes to enhanced production yields and improved productivity for customers.

Feel Free to Contact Us

We offer tailored grade recommendations and sample provision to meet your specific needs. For inquiries about transparent HIPS applications, please feel free to contact us.