-

-

Success Story | Vol.1

Seed tapes

- Read more

-

Who

With “Reduced Labor for More, Better Produce” as its motto, our partner company was established to promote and expand the seeder agricultural method. To broaden the acceptance of this method, the company set up production equipment for seeder tape, developed and produced seeder machinery, and produced seeder tape. The benefits of seeder agriculture include less labor in sowing (easy alignment of the seeded rows, thinning made unnecessary), uniform harvests, and lower amounts of defective crops.

What

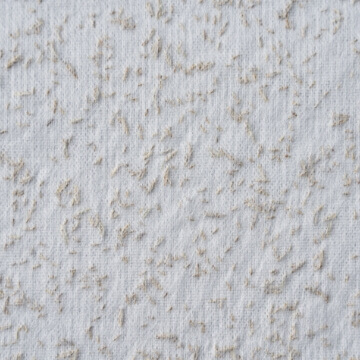

Initially, the materials used for the tape were paper, rayon paper and PVA. However, for paper and rayon paper, germination rates would worsen depending on the type of crop, necessitating a search for alternative materials. Bemliese™ has moderate thickness and openness, making it easy to use and was therefore adopted for the tape material. Currently, Bemliese™ and PVA are the only two varieties being used for tape material.

Why Bemliese™?

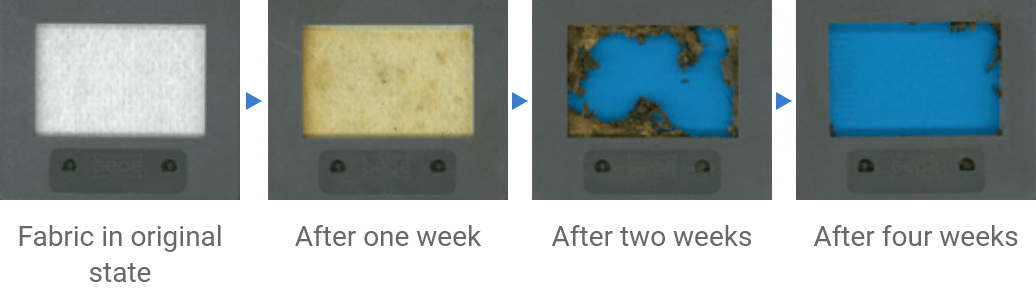

Bemliese™ has low basis weight (20g/m2) but as a cellulose nonwoven with thickness of high uniformity, the meshing has a moderate openness so that in comparison with conventional materials, the germination rate improved and the rate of defective crops decreased. Other companies’ cellulose nonwoven fabrics could not create a uniform low basis weight product, in addition to both corrosiveness and germination efficiency being poor.

The Challenge We Welcomed

Bemliese™ seed tape was mainly used for carrots and spinach, but the need to find other types of produce as new applications of Bemliese™ seed tape for our partner company led to additional exploration in collaboration with Asahi Kasei. Because produce ordinarily grows in one-year units, repair and improvement of any deficiencies also become measured in one-year units and take a very long time to implement. However, Asahi Kasei, by its commitment to a steady path of development and patient cooperation, was able to further build on the trust between partners.