-

-

Success Story | Vol.1

Bemcot™

- Read more

-

Who

In the course of a brainstorming session “once upon a time,” the Bemliese™ development team became aware that cotton gauze was being used in the manufacturing process for electronic parts. This spurred our development of industrial wipes, and marked the start of our partnership with one of Japan’s oldest (dating back nearly four centuries) and renowned producers of functional nonwoven products for industrial, medical and consumer use.

What

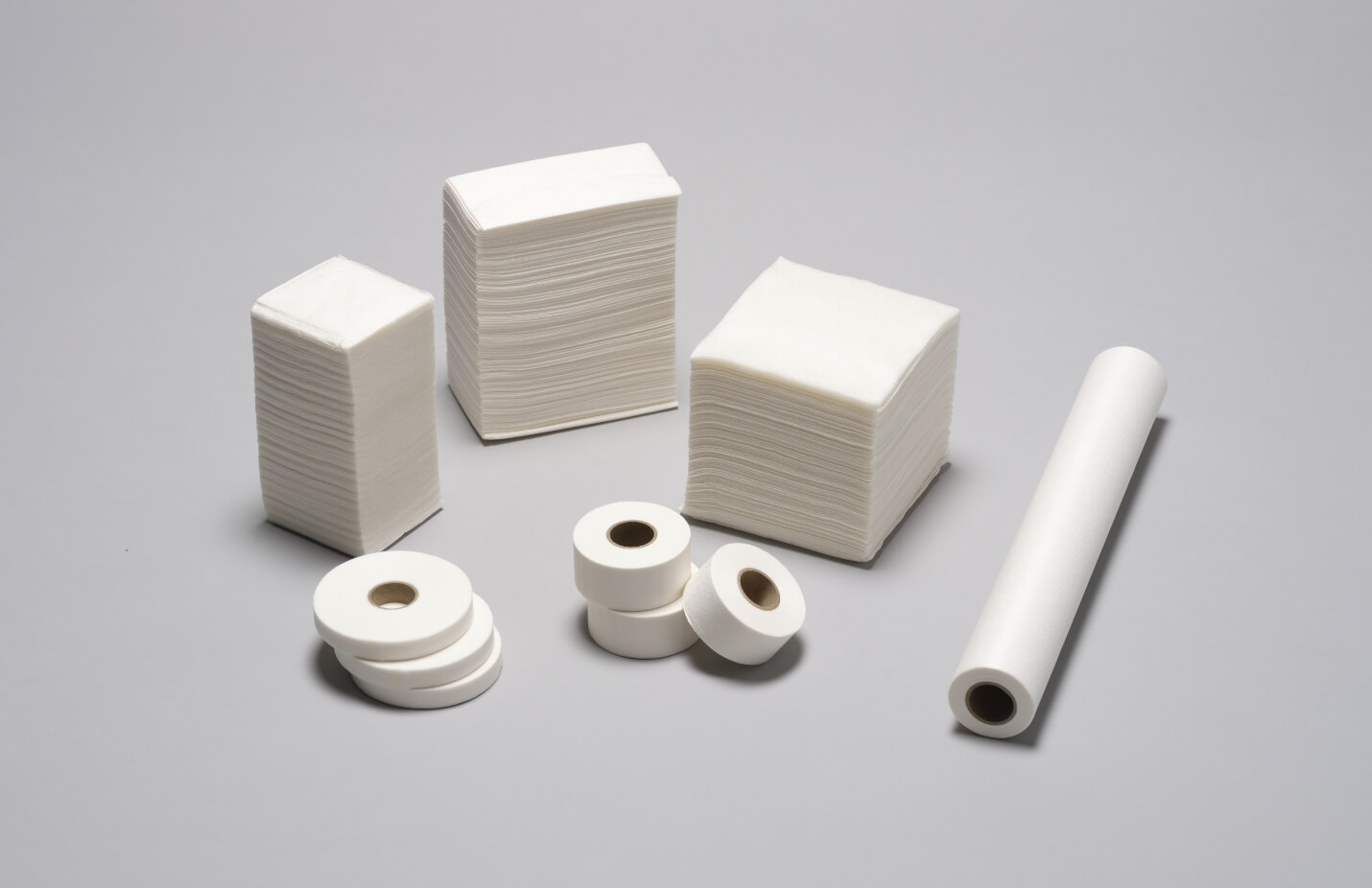

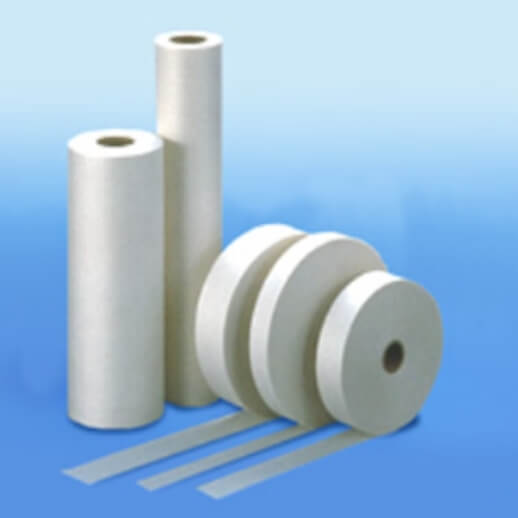

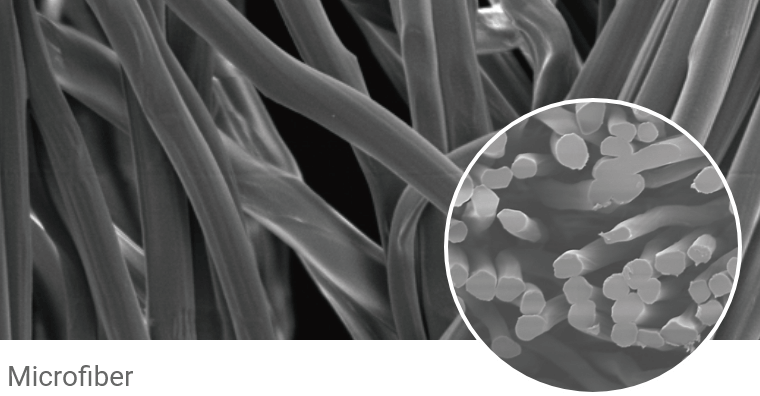

At the time of this initiative, the clean rooms for electronics parts were using wipes made of textile waste or paper, or medical cotton gauze. Compared to these wipes, Bemcot™ wipes are made from Bemliese™ and have superior low-lint properties. This aspect was prominently featured and led to immediate sales expansion. Semiconductors are produced in clean room environments that cannot tolerate lint, making the use of wipes from textile waste or paper problematic. At that point, Bemcot™ nonwoven wipes with the ability to limit dust/lint contamination were introduced, and has continued to grow in step with the advancement of the top semiconductor manufacturers in Japan as well as international market.

Why Bemliese™?

With the manufacturing circumstances noted above, Bemliese™ is an ideal choice because of its low dust/lint level, high absorbency, low impurities, minimal release of harmful gases if incinerated and other superior properties. These attributes set Bemcot™ apart and allowed it to become the pioneering brand of dedicated wipes for clean room environments.

The Challenge We Welcomed

In recent years with the rise of competing products, we have adjusted our sales strategy to implement joint sales with outside sales representatives. Furthermore, we are looking beyond the electronic parts segment to explore new sales opportunities and are conducting market research on a global scale.