About Wet Filters

Manufacturer

Manufacturer of wet filters is Asahi Kasei Advance Corporation

We provide the original yarn of the wet filters.

For your contact we may our agent or manufacturer to contact you directly.

Features of wet filters

Superior Chemical Resistance

Saran™ is resistant to acids and alkalis, and is insoluble in oils and most organic solvents, making it suitable for use in applications involving exposure to chemicals. (Note that it is soluble in some solvents such as tetrahydrofuran and cyclohexanone.)

Because Saran™ will not absorb water

Because Saran™ will not absorb water, it retains its strength under various humidity conditions. The lack of water absorption also makes it easy to remove the cake.

Excellent Flame Resisting

Saran™ fiber is inherently self-extinguishing, making the addition of flame-retardants unnecessary. This means consistent, uniform flame-retardant properties, free from variations which occur during flame-retardant compounding. Saran™ fiber plays an important role in applications requiring high flame-retardant properties.

RoHS(Restriction of Hazardous Substances)

Six compounds (Pb , Hg ,Cd, CrⅥ, PBBs, PBDEs) listed in RoHS are not contained in wet filters.

Type

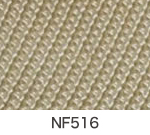

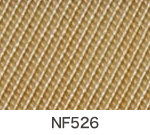

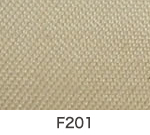

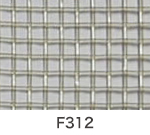

Please click on the small image to enlarge it * Discontinued product : NF711

Examples of Saran™ Filter’s use

Saran™ is used for “filter press”, ”leaf filter”, “anode bag for metallizing plating”, “filter for ion-exchange resin tower”

Anode Bags, Strainer

Anode Bags, Strainer Anode Bag

Anode Bag Bag Filter

Bag Filter  Filer in Suction extractor at Sewage plant

Filer in Suction extractor at Sewage plant Reference of Needlework goods using Saran™

Reference of Needlework goods using Saran™Specification

| PN. | Specification | |||||

|---|---|---|---|---|---|---|

| Textile weave | Width×Length* (cm) (m) |

Fineness | Mesh (/inch) |

|||

| Diameter | dtex | Warp | Filling | |||

| NF-516 | 4-leaf twill | 107×30 | 0.05mm ×60filaments |

2000dtex /60f |

48 | 25 |

| NF-526 | 4-leaf twill | 92×30 | 0.05mm ×60filaments |

2000dtex

/60f |

77 | 31 |

| F-201 | 5-harness satin |

124×50 |

0.20mm |

560dtex

/1f |

132 | 47 |

| F-312 | plain | 117×50 | 0.50mm | 3300dtex

/1f |

13 | 14 |

| F-5001 | 8-harness satin |

166×30 | 0.29mm | 1100dtex /1f |

85 | 40 |

| F-5003 | herringbone | 130×30 | 0.29mm | 1100dtex /1f |

92 | 32 |

| N-48 | basket | 160×30 | 0.29mm | 1100dtex /1f |

48 | 40 |

| N-64 | basket | 160×30 | 0.24mm | 780dtex /1f |

64 | 50 |

*approximated length