Example 5: Composite material

SunForce can be used with other types of materials to achieve various functions.

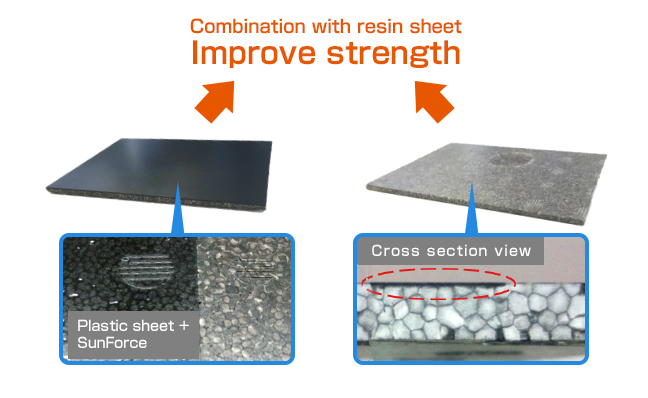

1With resin material

Resin parts can be molded simultaneously with SunForce to increase the strength of product. This combination can also improve the aesthetics of the product.

This can also be achieved by heat sealing for certain resins that have good adhesion properties.

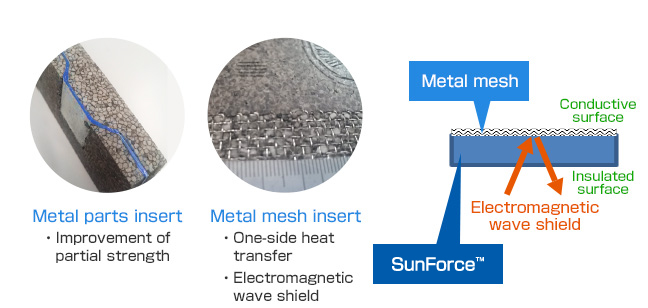

2With metal parts

Metal parts can be molded simultaneously with SunForce to increase strength of product. By utilizing metal, effects like electromagnetic wave shielding, heat transfer and dissipation can also be achieved.

Single sided heat conduction

Shutting out external heat while on the other hand, quickly dissipating heat from internal devices.

Electromagnetic wave shielding

Utilize metal mesh to reduce electromagnetic interference where needed. This composite (SunForce + metal mesh) is 10 to 20% lighter than conventional EMI shielding plastics.

By combining with SunForce, the product is able to maintain insulated on one side of the surface while metals and EMI shielding plastics turn conductive on both sides.

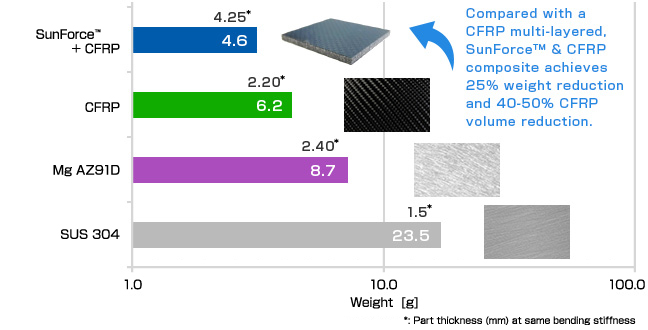

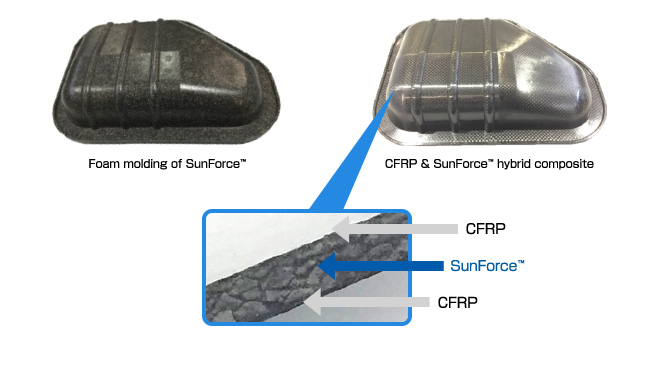

3With fiber material

SunForce can be used with carbon fiber reinforced plastics (using heat press).

Comparison of weight saving

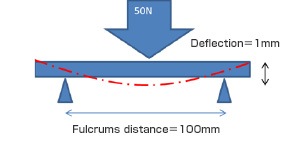

Comparison of Weight made by each material [Precondition] beam width: 20mm, distance from fulcrum: 100mm, center Weight: 50N, deflection: 1mm