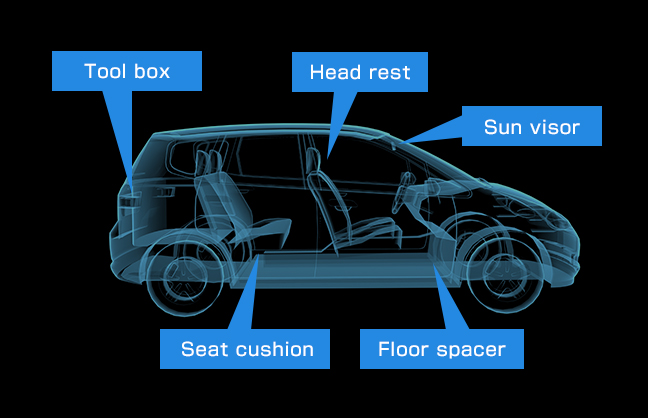

Automotive parts

MEF™ is suited as a component material for the automotive parts.

MEF™ has excellent characteristics such as

① Lightweight, ② Compressive recovery, ③ Toughness, ④ Flexibility,

⑤ Wear-resistant property, ⑥ Fire retardancy, ⑦ Low-VOC

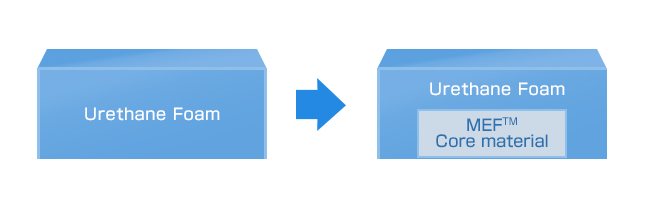

① Light weight

Expanded polyethylene MEF™ is lightweight foam product. The below illustration shows how MEF™ x30 (Density: 0.034g/cm3) can reduce weight as its density is only half of Urethane foam (Density: 0.068g/cm3).

25% weight-reduction

MEF™ offers reducing vehicle weight.

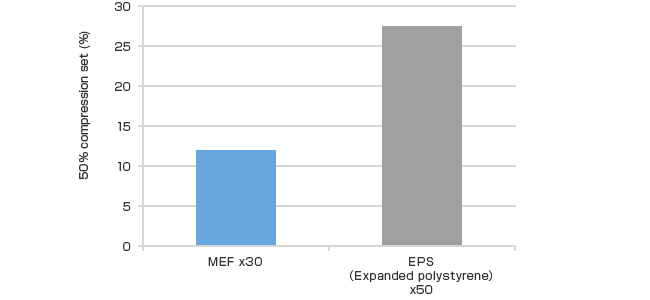

② Compressive recovery performance

MEF™ is expanded polyethylene, and has excellent compressive recovery performance, in comparison with expanded polystyrene.

50% compression set

Note:All values shown in this table are given as typical laboratory averages, intended to serve as approximate guide and not as specifications.

MEF™ has excellent compressive recovery performance, and is suited as a component material for various automotive parts.

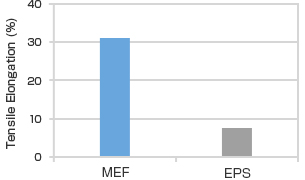

③ Toughness

MEF™ stretches well before tensile break compared with EPS and EPP.

Elongation

Note: All values shown in this table are given as typical

laboratory averages, intended to serve as approximate

guide and not as specifications.

Expanded Polyethylene MEF™ has excellent compressive recovery performance, and is suited as a component material for various automotive parts.

④ Flexibility

Expanded Polyethylene MEF™ is more flexible than expanded polystyrene.

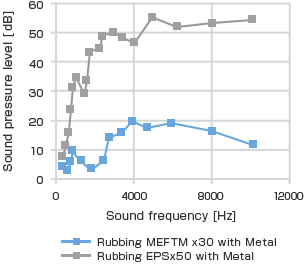

⑤ Wear-resistant property

MEF™ has small surface-friction drag, gives a rise to little friction sound.

Friction sound

Note: All values shown in this table are given as typical

laboratory averages, intended to serve as approximate

guide and not as specifications.

MEF™ has small surface-friction drag, resulting in a reduction in noises caused by surface-friction drag.

⑥ Flammability

MEF™ has passed the FMVSS 302 flammability test.

⑦ Low VOC

MEF™ is inorganic gas expanded polyethylene, and does not produce VOC.