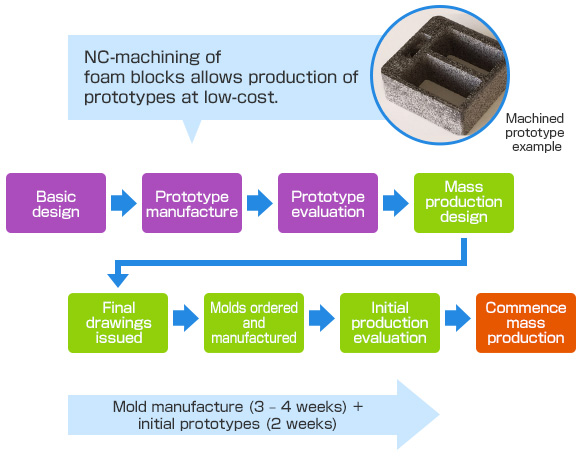

Short lead times

As with general foams, SunForce can shorten lead times for basic design and prototyping prior to mass production.

NC-machining can be used in the basic design stage, allowing verification on prototypes very close to the final mass-produced product. Molds can be readily and rapidly manufactured from aluminum, allowing transition to mass production within 6 weeks after drawings are finalized. Furthermore, since fine changes can be readily made to molds, detailed response to customer requests is possible.

The flow to mass production

Note: SunForce machined prototypes (physical properties of machined products)

Blocks of SunForce foam can be NC-machined cheaply to produce prototypes for evaluation prior to mass production (mold manufacture). However, it is important to be aware of the differences in the surface plastic layer, roughness, and machining marks in comparison to molded products when evaluating NC-machined prototypes.

x7 foam product

- Molded product:

- Flexural modulus 70MPa

- NC-machined product:

- Flexural modulus 53MPa