Total cost reductions

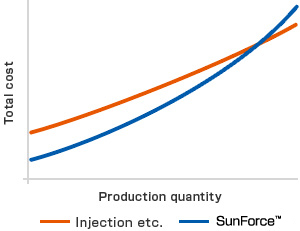

The use of SunForce permits mold fabrication at low-cost, and dramatically reduces the amount of resin used, and consequently enables total cost reduction,.

Particularly for components requiring thermal insulation and light weight, SunForce is a material that is cost-effective in terms of reducing the number of components required, reducing man-hours, and in reducing labor.

A comparison of lots of 10,000 components manufactured from SunForce and an injection resin product is shown below.

| Raw material | SunForce™ | Injected product |

|---|---|---|

| Units (per shot) | 4 | 1 |

| Plastic used | 30 | 100 |

| Mold cost | 45 | 100 |

| Raw material cost | 85 | 100 |

| Fabrication cost | 105 | 100 |

| Total cost | 90 | 100 |

* Foaming molds are inexpensive. A number of SunForce units of 4/shot is assumed in order to equalize the processing costs of each.