Asaclean™ is "your supporter" in the event of contamination defects

In plastic moulds, contamination defects are a significant production enemy. The high cleaning power of Asaclean™ removes this contamination quickly and is a saviour in reviving high productive productivity.

Immediate contamination removal with Asaclean™

The resin inside the machine deteriorates when you operate a plastic moulding machine for an extended period. If it gets mixed in with the moulded product, foreign matter defects will occur. This contamination significantly impacts yield, and if the machine needs to be disassembled and cleaned, production will not be possible, resulting in a significant opportunity loss.

Asaclean™ effectively removes contamination with its mighty cleaning power, solving the problem of contamination generation at its root. Therefore, you can reset the inside of the moulding machine to a clean state without troublesome and time-consuming teardown.

80%

With Asaclean™ cleaning the inside of moulding machines, you can reduce the incidence of defective products by approximately 80%*.

Support early resolution of contamination with grade selection and worldwide network

Asaclean™ offers powerful grades dedicated to contamination removal for different resins, such as IMX Grade and newEX Grade. We will assist you in selecting the best grade for your situation. We also have a worldwide sales network for quick response to sudden contamination outbreaks.

Asaclean™ eliminates contamination with compatibility

Asaclean™ is engineered to have excellent compatibility with various resins using polymer properties. This compatibility enables Asaclean™ to blend with dirt and eliminate it out together. In addition, our advanced compounding technology has realized a high cleaning power to eliminate dirt.

Previously, color changes, especially cleaning of cyanine blue, required about 10 tons of LD, HD, and other materials, taking nearly 35 hours. However, with Asaclean™, it is possible to clean with only 300 Kg to 400 Kg of material in about 8 hours. This has significantly reduced both material loss and time.

Packaging industry user | IMX Grade

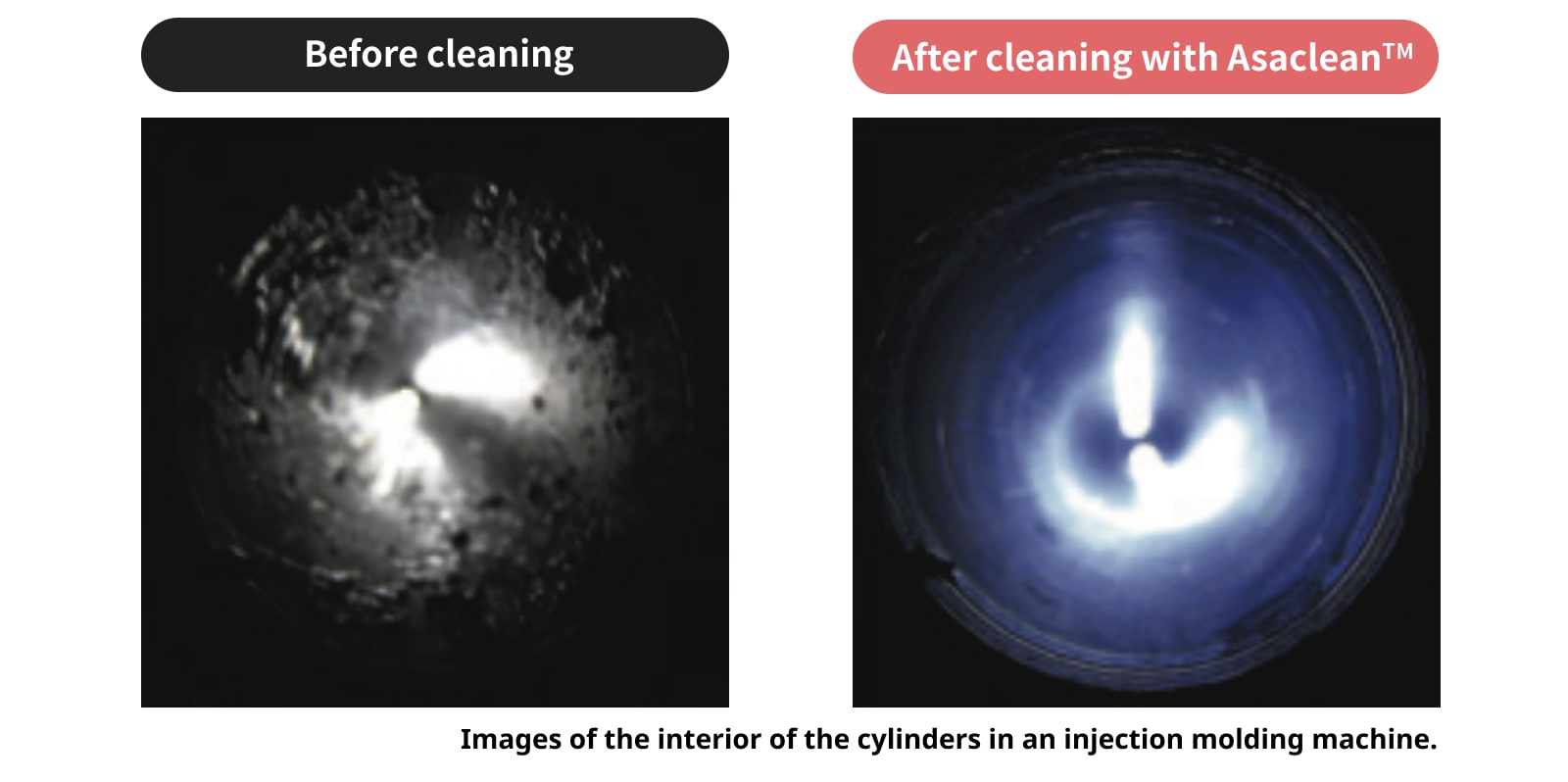

Asaclean™ makes the inside of the cylinder sparkling clean

While teardown can clean the screws, it is not easy to polish the inside of the cylinder. Cleaning with Asaclean™ removes dirt from the inside of the cylinder.

How do we prevent contamination from occurring?

You can use Asaclean™ as a saviour against contamination, but even so, it does not mean that you can eliminate losses due to contamination. To maximize productivity, "preventive measures" are necessary to prevent contamination from occurring in the first place.

Asaclean™ is also effective in preventing the occurrence of contamination. In some cases, Asaclean™ reduced contamination defects by 99% by combining regular cleaning and sealing when you stop the machine. Please consider the new era of moulding machine maintenance, in which Asaclean™ prevents contamination defects by keeping the inside of the machine clean at all times.