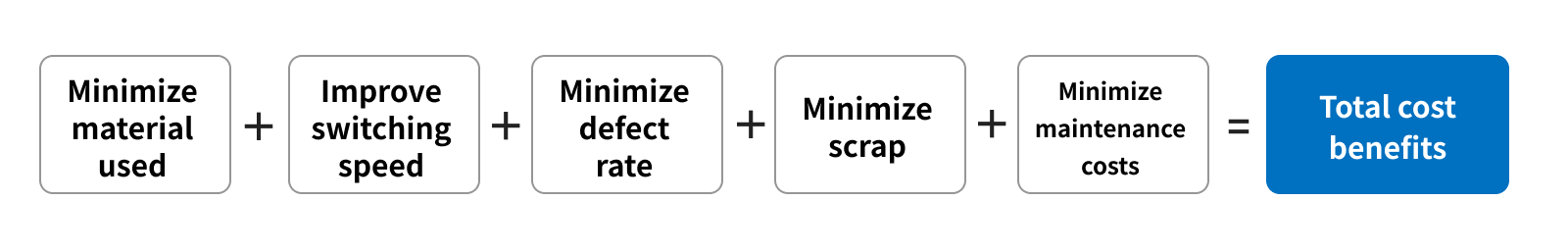

The optimisation of material replacement generates profit

In plastic moulding, there are not a few who frequently switch colours and materials. This material changeover costs a lot. This is especially true when changing from a dark colour such as black to a natural colour. Asaclean™ can realize significant cost reductions by maximizing the efficiency of these material changeovers.

Efficient material changeovers improve productivity

In the plastic moulding field, changeover in product colour and material is usual daily. In particular, switching from a dark-coloured material such as black to a light-coloured material takes time and wastes your materials.

Asaclean™ effectively solves these issues. Compared to conventional methods, using Asaclean™ remarkably reduces the resin required to remove previous resins while reducing the time required, thus considerably improving production efficiency.

75%

With Asaclean™, you can reduce the total usage of resin considerably*.

Asaclean™ eliminates contamination with compatibility

Asaclean™ is engineered to have excellent compatibility with various resins using polymer properties. This compatibility enables Asaclean™ to blend with dirt and eliminate it out together. In addition, our advanced compounding technology has realized a high cleaning power to eliminate dirt.

Cost reduction effect with Asaclean™

Some customers new to Asaclean™ as a means of cleaning their moulding machines may think that an expensive purging compound may be outside our budget. However, many customers worldwide have realized significant cost savings and efficiency improvements with Asaclean™.

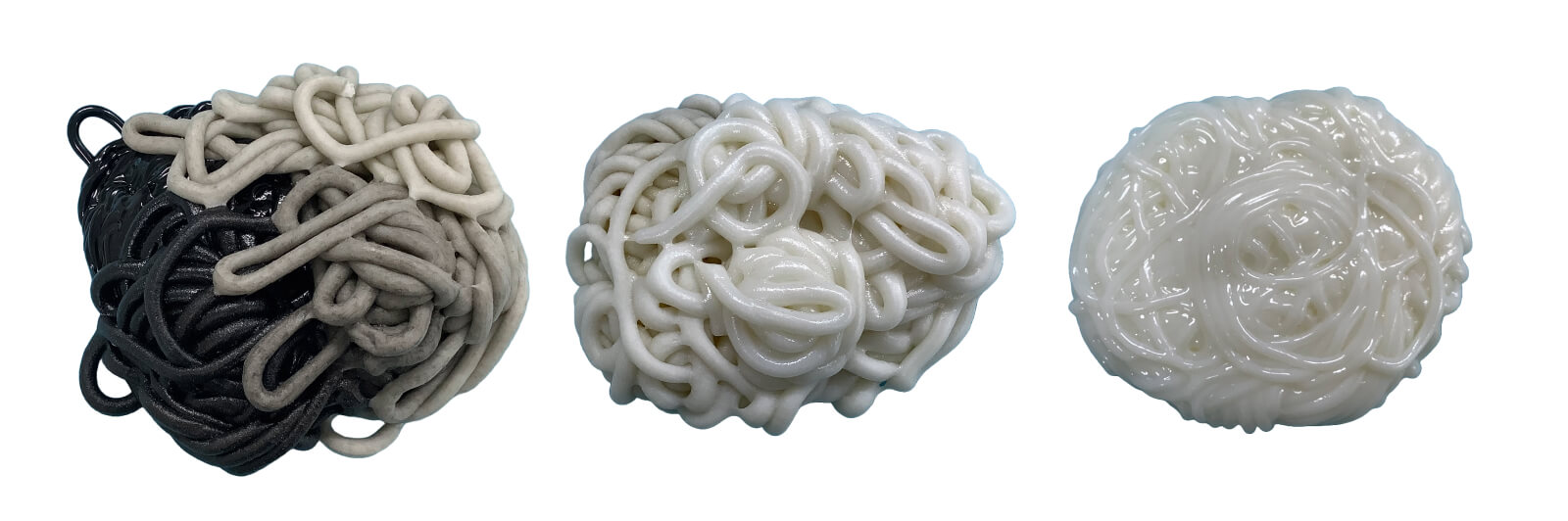

Case: Changeovers from deep colour to natural colour

The material was switched from black ABS to white HIPS in the injection moulds. 3.8 kg of resin was used to replace HIPS alone, whereas the amount of resin used dropped to 0.8 kg when cleaned with Asaclean™ U Grade. This changeover reduces more than 75% of total resin use. We saved time and materials.

We had been using crushed and other materials, but the colour changeovers from black to white required a full day of dripping the next material. When we tested 20 kg of UP, the colour changeover was completed in just one hour, significantly miing loss and time.

Blow extruion moulding user | UP Grade