Thorough cleaning of injection moulding machines with Asaclean™

Injection moulding sites have the highest frequency of material and colour changeovers. Problems such as prolonged resin replacement, defects, and contamination or unintended colours are commonplace. In addition, resin often remains in nozzles, check rings, and other small areas. Asaclean™ solves these injection moulding problems.

Asaclean™, the right choice for injection moulding

It is no exaggeration to say that customers who use injection moulding machines are the ones who need purging compounds the most. Injection moulding sites often require frequent colour and material changeovers. In addition, injection moulding machines have a structure with many dead spaces, such as nozzles and check rings, and the resin remaining inside the machine is prone to deterioration and the formation of contamination.

The reality is that plastic moulding involves a thousand different resins, temperatures, methods, and other conditions depending on each plant and product. It isn't easy to realize a cleaning method that can accommodate such diversity. However, Asaclean™ offers a variety of grades, from general-purpose to special-purpose, to satisfy all kinds of customers.

Easy, thorough cleaning of all areas

Asaclean™ uses polymer properties and resin compatibilizer technology to achieve high cleaning performance. It has a proven track record in the rapid cleaning of hot runners, thorough cleaning of screws and cylinders, valve gates and nozzle tips, and check rings.

Cleaning various resins, such as POM, PP, ABS, PC, PC/ABS and PA6, is standardized to "U Grade". No contamination defects and No problems.

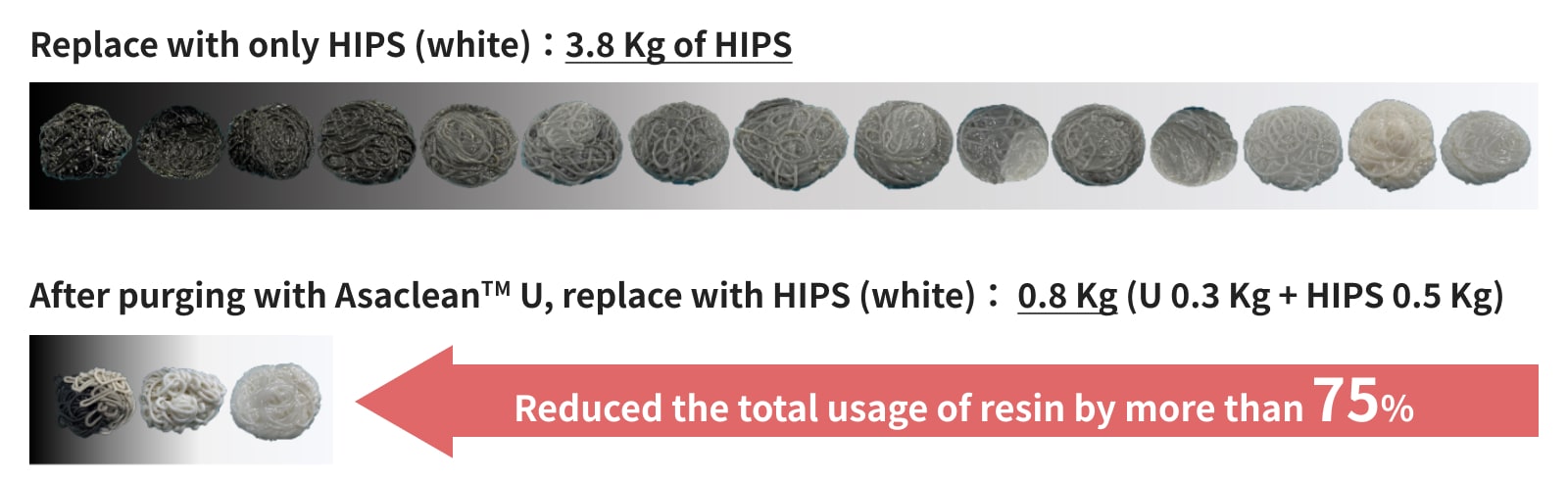

Automotive industry user | Injection moulding | U Grade

For customers who have dozens of colour and material changes per week.

With Asaclean™, you can significantly reduce the amount of resin required for cleaning and the time required compared to conventional methods. You can realize that this efficiency considerably impacts injection moulding, where frequent colour and material changes are needed.

NewEX Grade is the best solution for removing carbonized contamination.

Automotive industry user | Injection moulding | newEX Grade

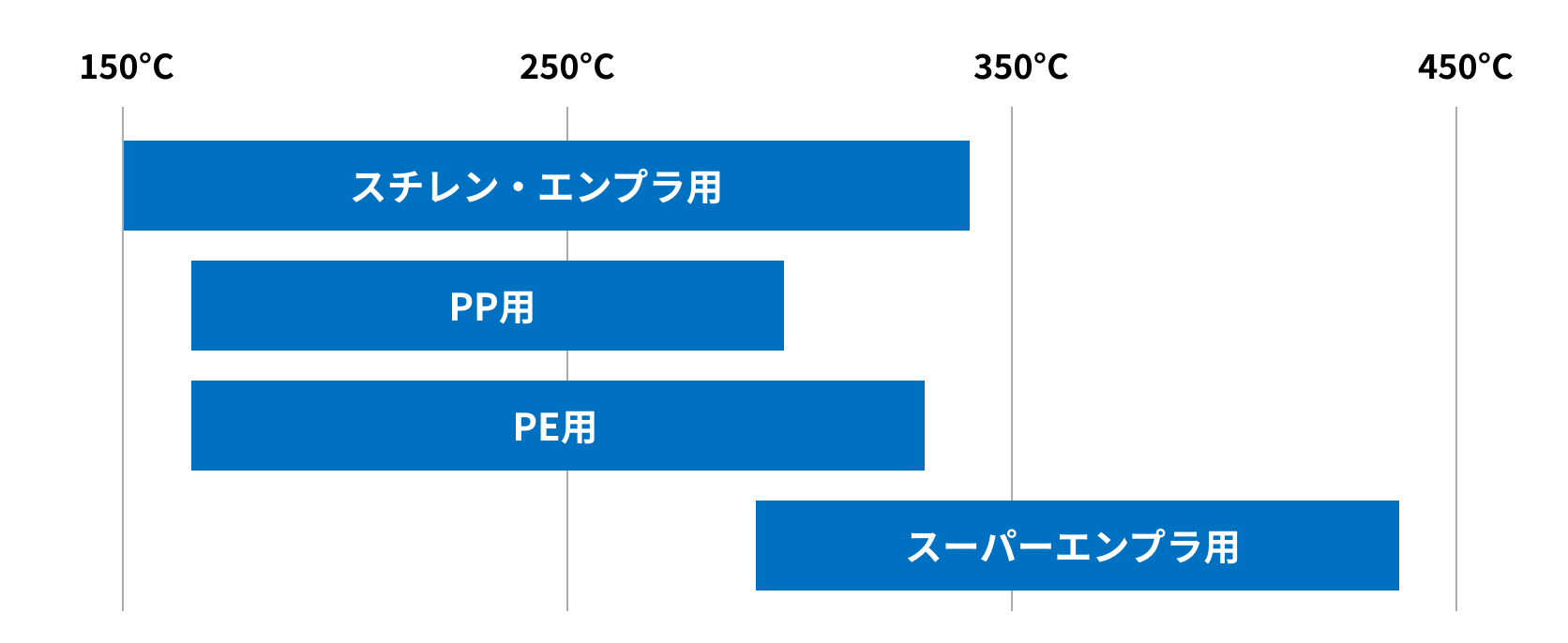

Wide grade line-up for wide resins

Asaclean™ is available in a wide range of grades to suit different resins and applications and covers moulding temperatures from 150℃ to 420℃, from general-purpose resins to super engineering plastics.