‘Prevention’ is a shortcut to peak performance

Continuous use of the moulding machines will cause black spots and contamination due to the accumulation and thermal degradation of the internal resin film. If left unchecked, the cost increase due to the generation of defective products will continue, and disassembly and cleaning, which eventually cause lost opportunities, is inevitable. With Asaclean™, the "anticipated cost burden" can be significantly reduced.

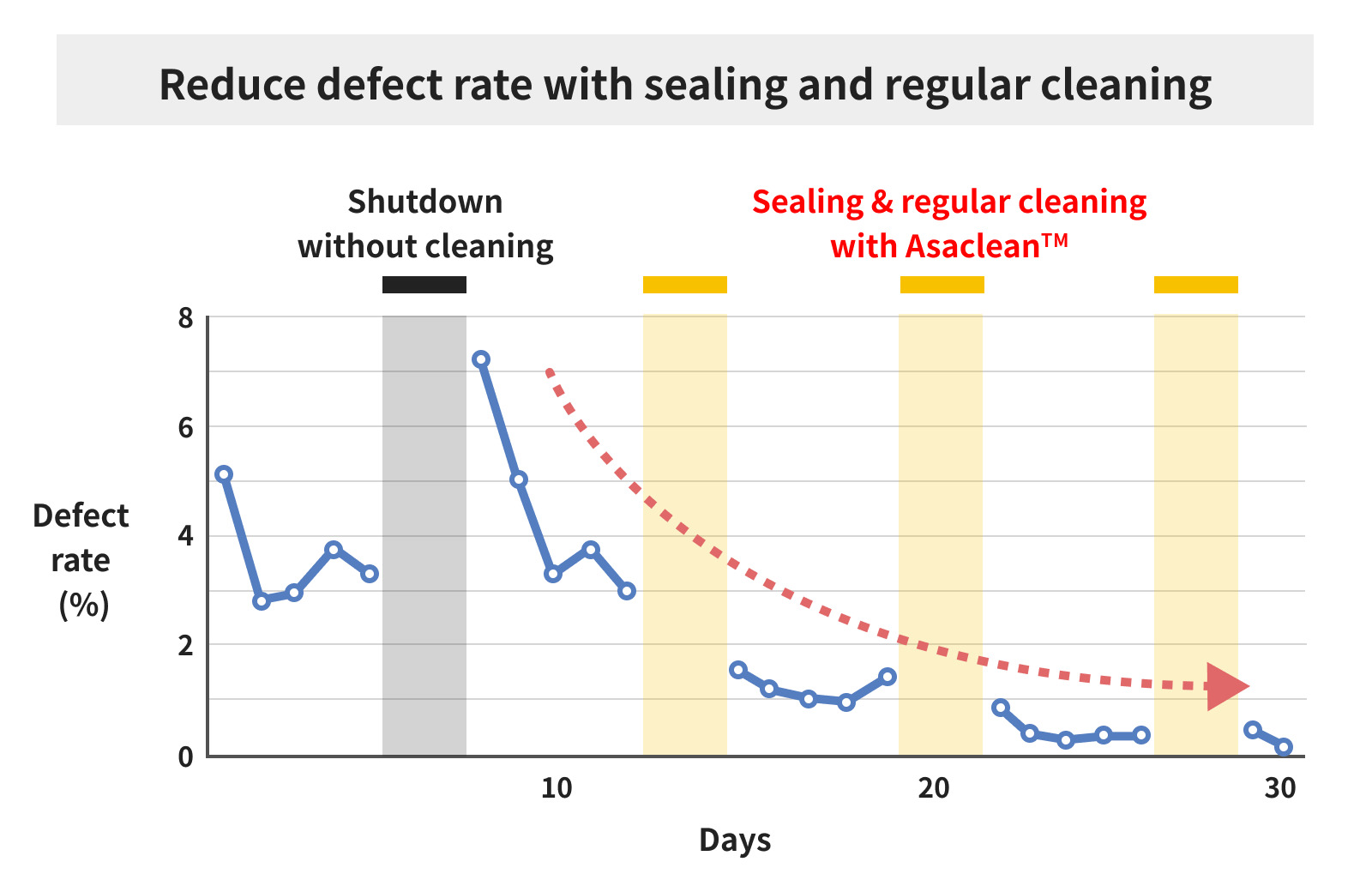

The introduction of regular cleaning with Asaclean™ considerably improved productivity.

When you operate a moulding machine for an extended period, there is a risk that the resin accumulated inside the machine will deteriorate thermally, become black spots, and become contaminated. Contamination can lead to contamination of the product, resulting in poor quality. Furthermore, if the black spots and contamination become severe, they cannot be treated with ordinary purging compounds, and time-consuming and costly overhaul cleaning becomes indispensable.

Regular cleaning with Asaclean™ effectively prevents these problems and significantly reduces the contamination defect rate. As a result, less frequent teardown contributes to increased productivity.

Furthermore, there have been cases where combining sealing during operation stoppages with Asaclean™ has cut the probability of contamination defects by 99%. The "preventive effect" of Asaclean™ is the best solution for maintaining high productivity.

99%

Regular cleaning and sealing with Asaclean™ reduces the incidence of defective products by up to 99%*.

We cleaned with raw materials involving a material change from ABS/black to PP/black, but regular cleaning with UP grade is now performed. As a result, we could significantly reduce the defect rate from 10% to less than 1%.

Transportation equipment manufacturer | Quality assurance representative

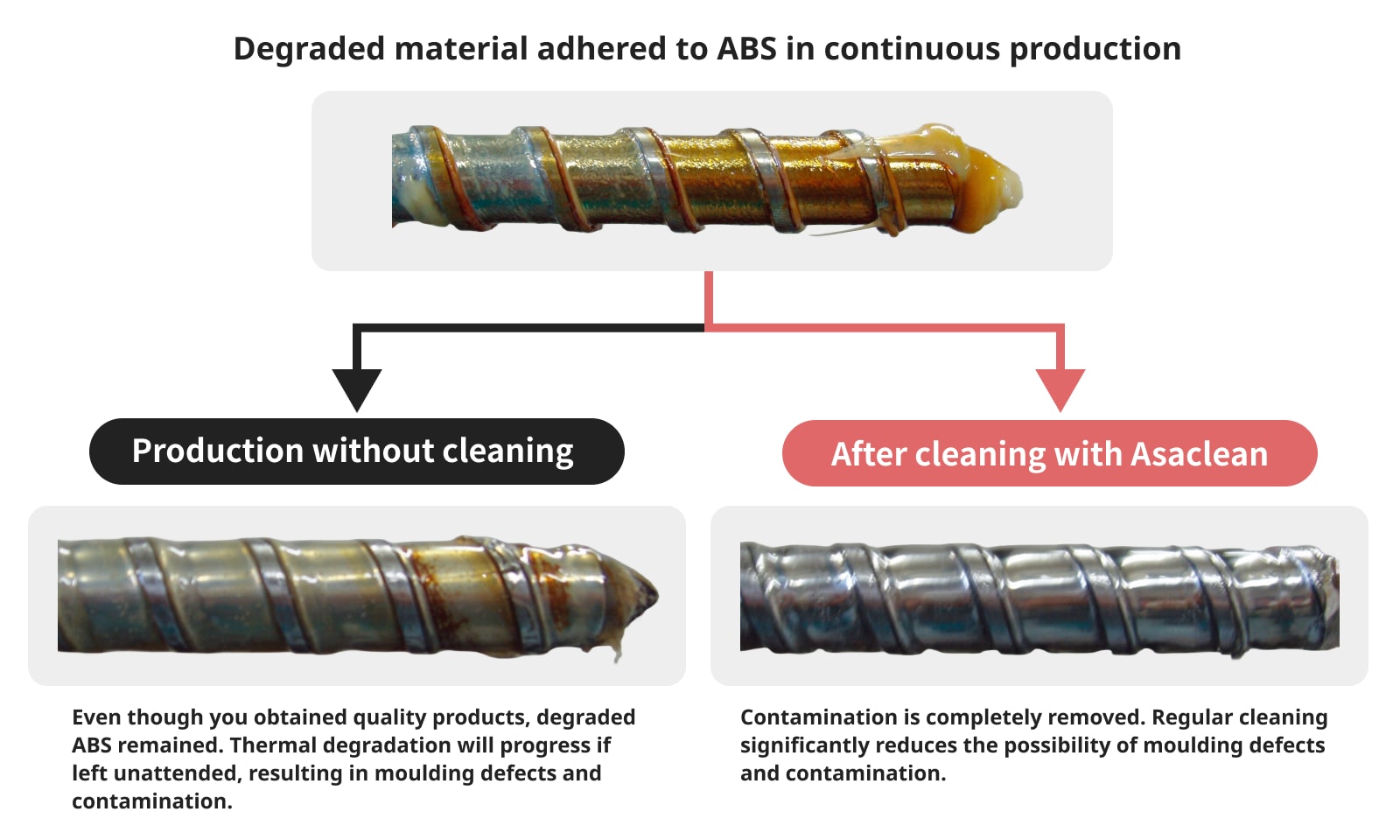

Regular cleaning prevents the formation of contamination.

At most plastic moulds, even if you think you are getting good products, there is usually a buildup of contamination inside the moulding machine.

This is because the resin film that is gradually laminated inside the mould continues to deteriorate thermally, and the accumulation of contamination progresses unnoticed. Eventually, contamination will occur, which is irreversible. By utilizing the "preventive effect" of regular cleaning with Asaclean™, it is possible to maintain a state in which contamination does not occur in the first place.

We mainly mould POM, PP, PC, and ABS and produce in small quantities and high mixes. Material changeover with U Grade and regular cleaning with IMX and newEX Grade solved contamination problems. Even though it may be troublesome, regular cleaning with Asaclean™ reduces losses and has various advantages.

Automitive industry user | U/IMX/newEX Grade