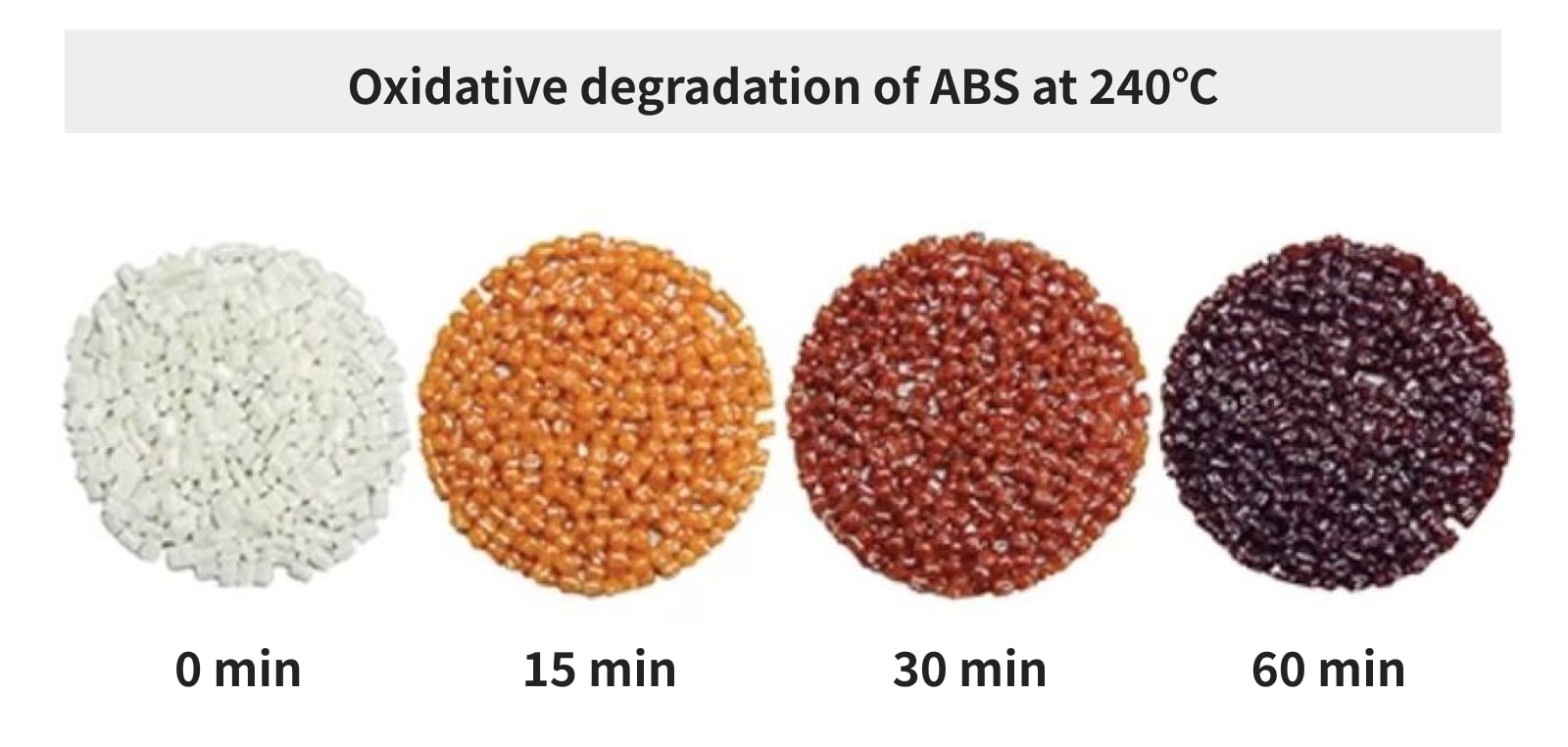

Eliminates oxidative degradation during shutdown

Inside a plastic moulding machine at rest, the residue is deteriorating due to residual heat and oxygen in the air. As a result, problems such as contamination entering the machine during start-up are likely to occur. With Asaclean™ to seal the machine, you can solve this potential problem.

Sealing with Asaclean™ to prevent degradation during shutdowns

It is common practice to empty the interior of plastic moulding machines during shutdowns, but this can cause unexpected quality problems. The residual resin deteriorates and oxidizes due to residual heat, and there is a risk of contamination entering your products during start-up.

However, keeping the machine filled (sealed) with Asaclean™ solves this problem. Asaclean™ shuts out oxygen and prevents thermal degradation due to residual heat. This approach minimizes quality problems during start-up and considerably improves production efficiency.

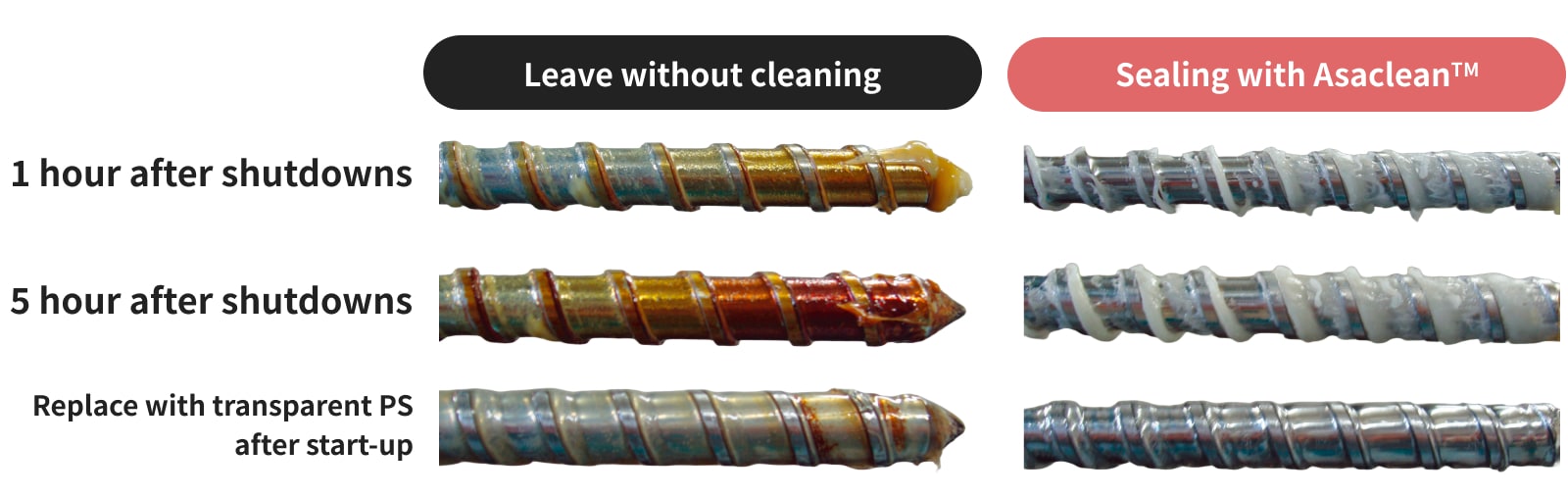

With Asaclean™, you can minimize losses after machine start-up

Asaclean™ is a purging compound specially designed for resin moulding machines, and its high compatibilization technology allows it to clean a wide variety of resins efficiently. By filling the inside of the cylinder with Asaclean™ after cleaning, you can keep the inside of the machine clean and stop it.

Sealing with Asaclean™, which has good thermal stability, prevents thermal degradation and oxidation of the resin due to residual heat from the machine after shutdown. Furthermore, purging at the machine start-up washes out any remaining degradation material. As a result, you can prevent problems after start-up and reduce time loss and defect rate.

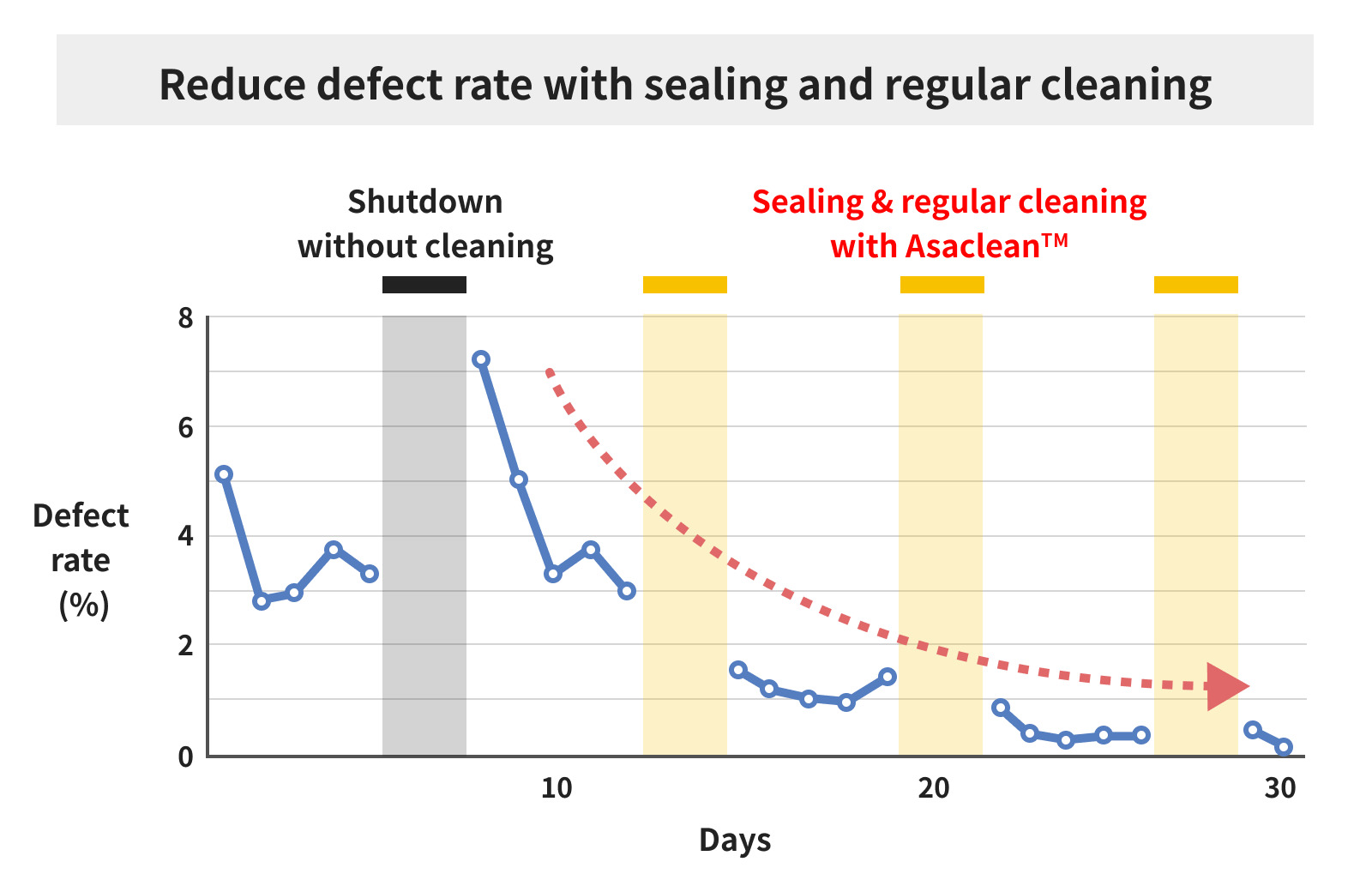

Regular cleaning and sealing ensure a trouble-free production

Sealing with Asaclean™ is effective for problems such as contamination due to oxidative deterioration of residual resin after shutdown. Still, you can considerably reduce the probability of defects by combining sealing with regular cleaning. Even if you can produce good products, contamination can accumulate unnoticed, eventually causing irretrievable defects. Combine regular cleaning with Asaclean™ to realize a trouble-free production.

Asaclean™ reduced contamination defects with Xyron, m-PPE. Specifically, we conduct regular cleaning every two weeks using newEX and newUP Grade. During holidays, we seal the machine with newUP Grade. Sealing with Asaclean™ reduced defects after holidays from 3% to 0.3%.

Erectronics industry user | newEX/newUP Grade