Purging Compound to Prevent Defects and Improve Production Efficiency

In the facilities of plastic molding, defects caused by color changes, material changes, and contamination or color irregularities are common. This issue is not limited to injection molding but is also a common challenge in various molding methods such as extrution. By using purging compound, it is possible to efficiently clean the previous processing material adhered to the inside of the cylinder and screw, and replace it with the next processing resin. As a result, it greatly contributes to improving the work efficiency of the production and preventing defects in your products.

What is purging compound?

Purging compound is a specialized cleaning material developed to effectively remove residual resin adhered to the inside of cylinders and screws in plastic molding. For example, in plastic molding, residual resin remain during material or color changes can affect the next molded product, causing defects such as black spots and contamination. These issues can lead to quality problems and reduced yield of molded products. The major advantage of purging compound is its ability to prevent such troubles, reduce material loss, and enable quick cleaning.

Purging Compound: Essential for Boosting Efficiency in Plastic Molding

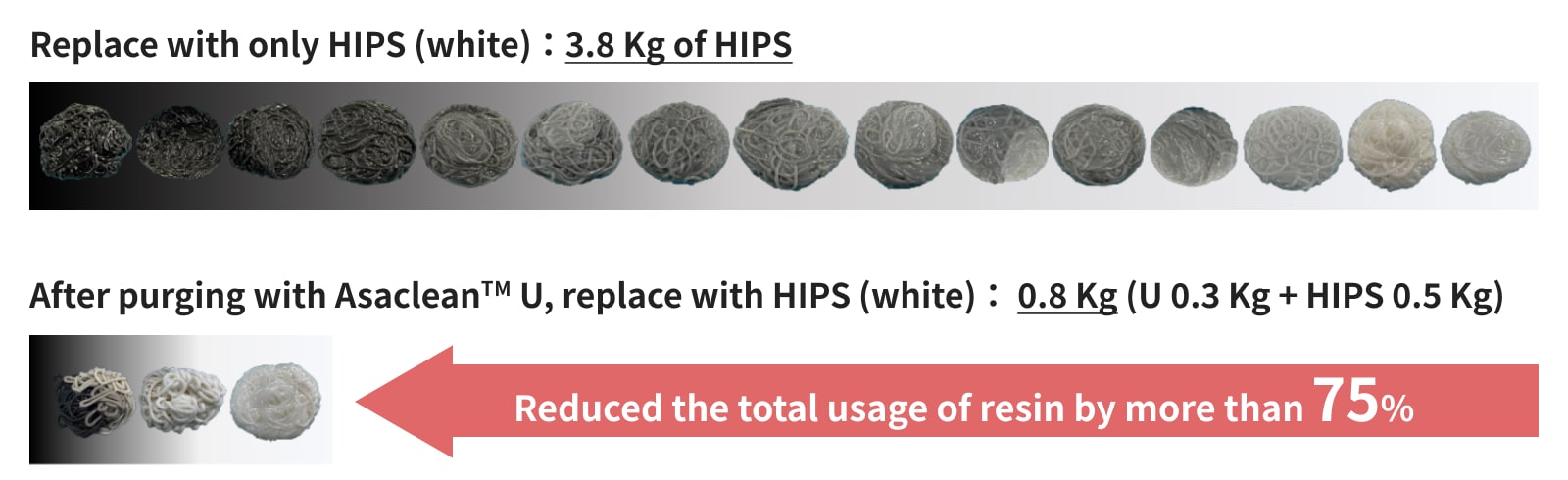

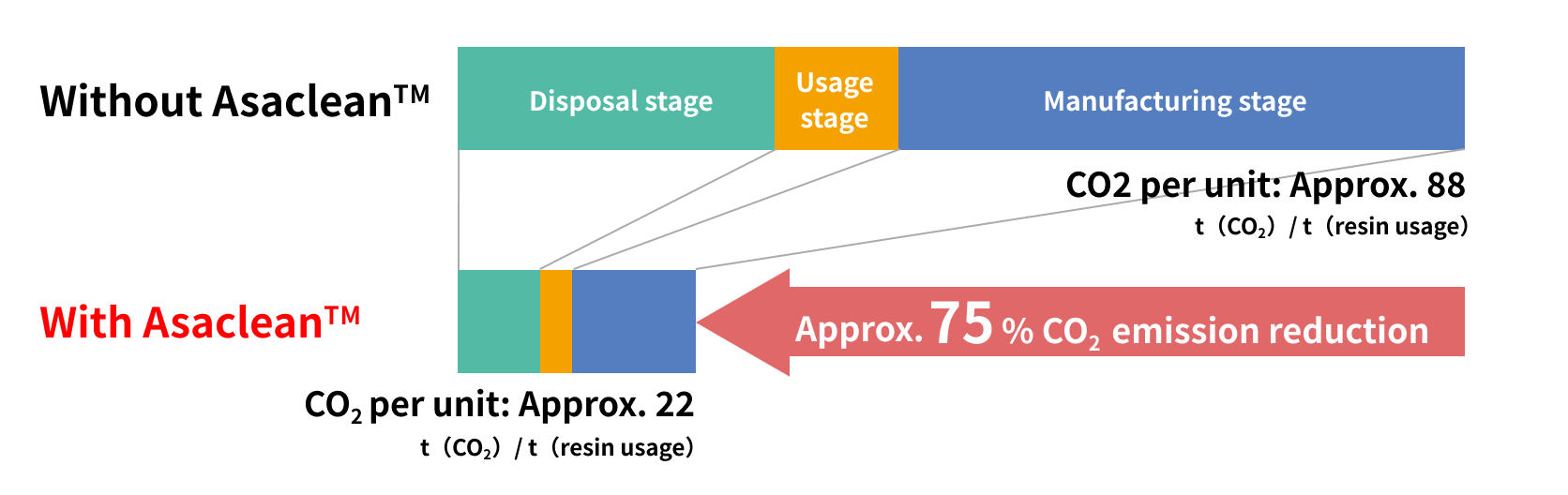

Continuing plastic molding without using purging compound results in the consumption of a large amount of virgin material (next processing resin) every time there is a material or color change. This leads to increased costs and environmental impact due to the used virgin material. Additionally, cleaning with virgin material prolongs the time required for switching, ultimately reducing production efficiency.

On the other hand, using purging compound allows for efficient cleaning, quickly bringing the inside of the cylinder to a clean state and reducing the amount of material used. Furthermore, by thoroughly removing residues, it prevents defects such as black spots, burns, and color irregularities, significantly improving the quality of products. In recent years, environmental considerations have become increasingly important, and efforts to reduce CO2 emissions by minimizing material loss are being sought in all areas of plastic molding. From this perspective, the usefulness of purging compound is increasing.

The Perfect Purging Compound: Maximum Cleaning Power, Minimal Residue

When selecting a purging compound, there are several factors to consider, but high cleaning power and low residuals are particularly important. High cleaning power ensures that the resin adhered to the inside of the screw is thoroughly removed in all plastic molding scenarios, including injection molding, blown film extrusion , and extrution. Additionally, if the purging compound itself remains after cleaning, it can negatively impact the quality of the next molded product, making low residuals an essential feature for reducing defects.

Furthermore, since purging compounds are consumables used repeatedly, it is necessary to consider the total cost, including cleaning efficiency, rather than just pursuing low cost. Superior purging compounds can lead to long-term benefits by reducing material loss and work time, ultimately lowering expenses.

Experience the High-Performance Purging Compound, Asaclean!

Asaclean demonstrates its high cleaning power not only in injection molding but also in extrusion and blown film extrusion, preventing defects such as black spots, burns, and scorching. Additionally, its excellent low residual properties ensure that almost no residue remains after cleaning, allowing for a smooth transition to the next production. Furthermore, the high cleaning efficiency of Asaclean contributes to reducing material usage and work time, thereby lowering costs for materials, electricity, and labor. These benefits have earned Asaclean significant trust in the plastic industry, making it a key player in supporting high-quality and efficient production.