We can save money while being sustainable

Today, we are required to be environmentally friendly. Many people are aware of its importance but face the increased costs of doing it. With Asaclean™, you can reduce the total cost of product manufacturing while reducing CO2 emissions.

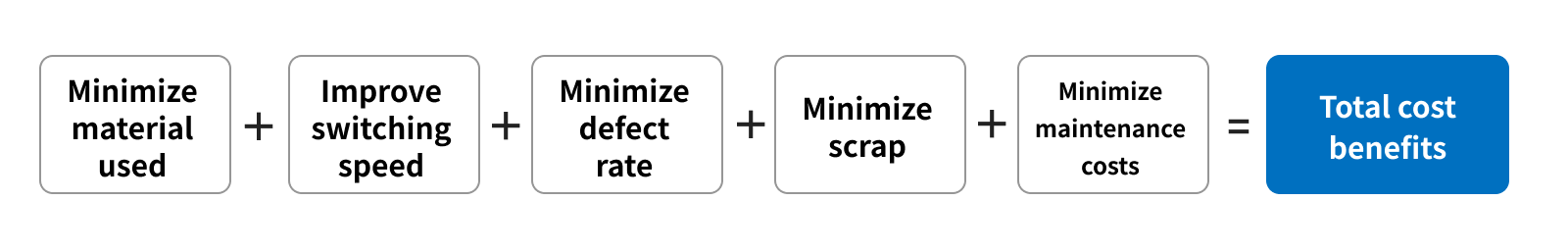

Asaclean™ improves the overall cost structure

Some customers new to Asaclean™ as a means of cleaning their moulding machines might think that an expensive purging compound may be outside our budget. However, many customers worldwide have realized significant cost savings and efficiency improvements with Asaclean™.

For example, you can reduce material losses during colour and resin changes by up to 90% with the high cleaning power of Asaclean™, thereby significantly reducing material costs. Also, we can minimize your time and moulding defects by selecting the appropriate grade. Less purging compound is used, which reduces waste and saves maintenance costs and time.

We could significant improvements in efficiency and reduction of material loss in the colour changeover of large interior parts.

Automotive industry customer | Injection moulding | UR / HR Grade

Asaclean™ can achieve reducing CO2 emissions

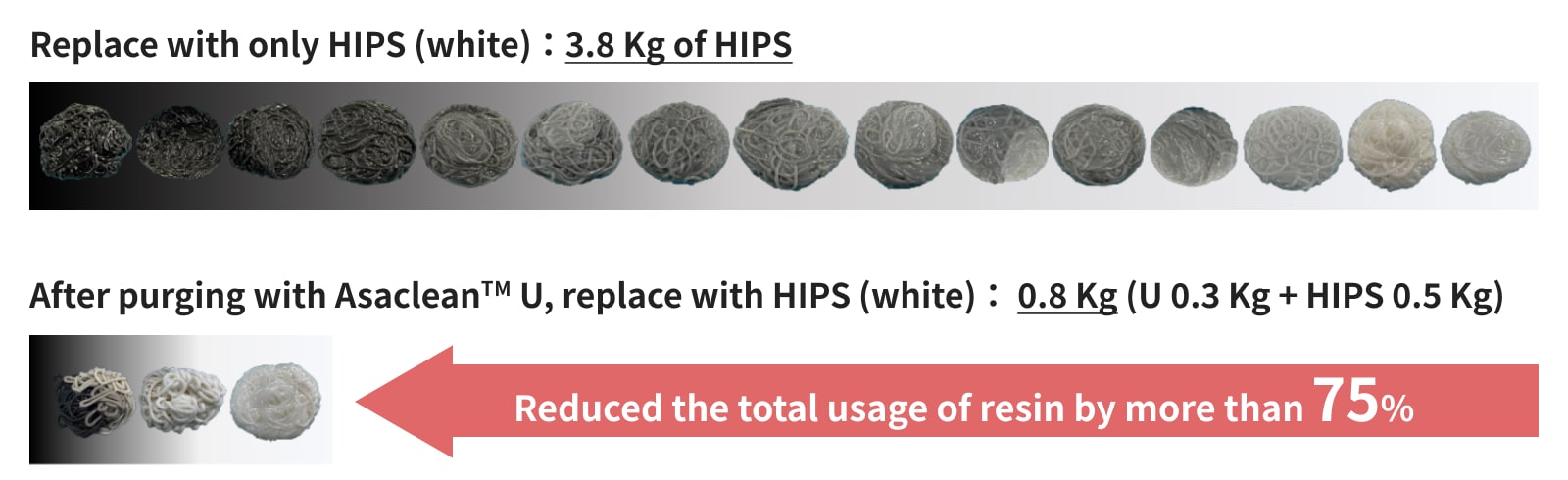

Asaclean™'s high cleaning power reduces the resin used and time lost during the material changeover. Saving operation time and resin used contributes to reducing CO2 emissions.

For example, when switching from black ABS to white HIPS, the amount of resin used is 3.8 kg when replacing HIPS alone, whereas the amount used drops to 0.8 kg when cleaned with U Grade. This change represents a more than 75% reduction in resin use.

Asaclean™ breaks the preconception, ‘Being sustainable can be expensive.’ while saving money.

Learn more about the effect of reducing CO2 emissions with Asaclean™.

The company contributed considerably to reducing the loss of primary materials due to insert moulding products. We could lower the defect rate from 13% to 0.3%.

Automotive industry user | Injection moulding | newEX / SL Grade