For where you require extreme efficiency

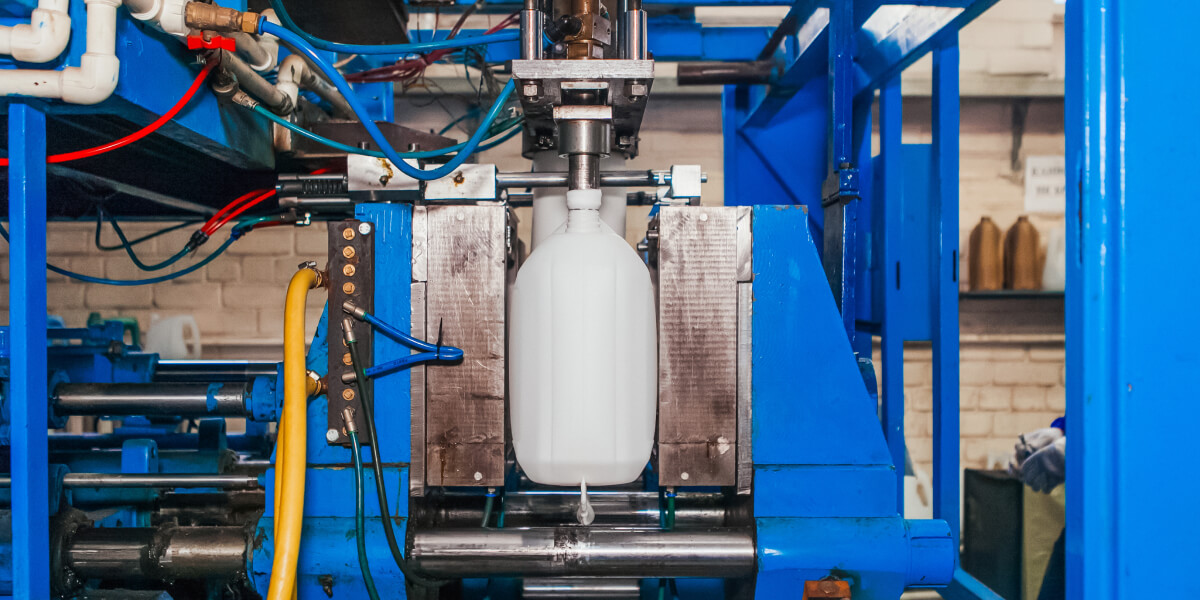

In extrusion blow moulding, it's necessary to minimize the inefficiency of resin and downtime as much as possible. In many cases, you require frequent material and colour changeovers. Asaclean™ can perform such material changes with high efficiency, speed, and low cost.

Asaclean™ solves unique problems with extrusion blow moulding.

In many extrusion blow mouldings, maximizing production efficiency is extremely important. Even though you should minimize downtime as much as possible, cleaning the accumulator's head and removing contamination takes 8 to 24 hours.

It is also a site where headaches abound, such as the time it takes to switch from dark to light colours and the contamination by easily burnt PE.

With its high cleaning capability, Asaclean™ efficiently solves these challenges in extrusion blow moulding. Users of extrusion blow moulding machines highly regard customers of extrusion blow moulding machines. In particular, it is indispensable for blow moulders who often work with small lots of products and short delivery times.

Significantly Reduced Material and Color Change Times in Extrusion Blow Molding

Material and color changes in the extrusion blow molding process can be greatly streamlined by using Asaclean™™. By using Asaclean™™, the time required for complete color removal is significantly reduced, minimizing production line downtime and enhancing the efficiency of continuous production.

Until now, we have used regrind materials, but we have had to spend an entire day pouring out the next material to change the colour from black to white. After testing 20 kg of UP Grade, the colour changeover was completed in just one hour, significantly reducing loss and time.

Blown moulding user | UP Grade

Usually, we require 5 to 10 kg, but with Asaclean™, we could complete its cleaning in about 2 kilograms.

Blown moulding user | UF2 Grade