Prevent Defects and Enhance Operational Efficiency with Purging Compound

In the plastic molding facilities, troubles and defects during molding are significant challenges. This article explains the mechanisms by which defects occur in plastic molding and the countermeasures using purging compounds to address these defects.

The Mechanism of Defects

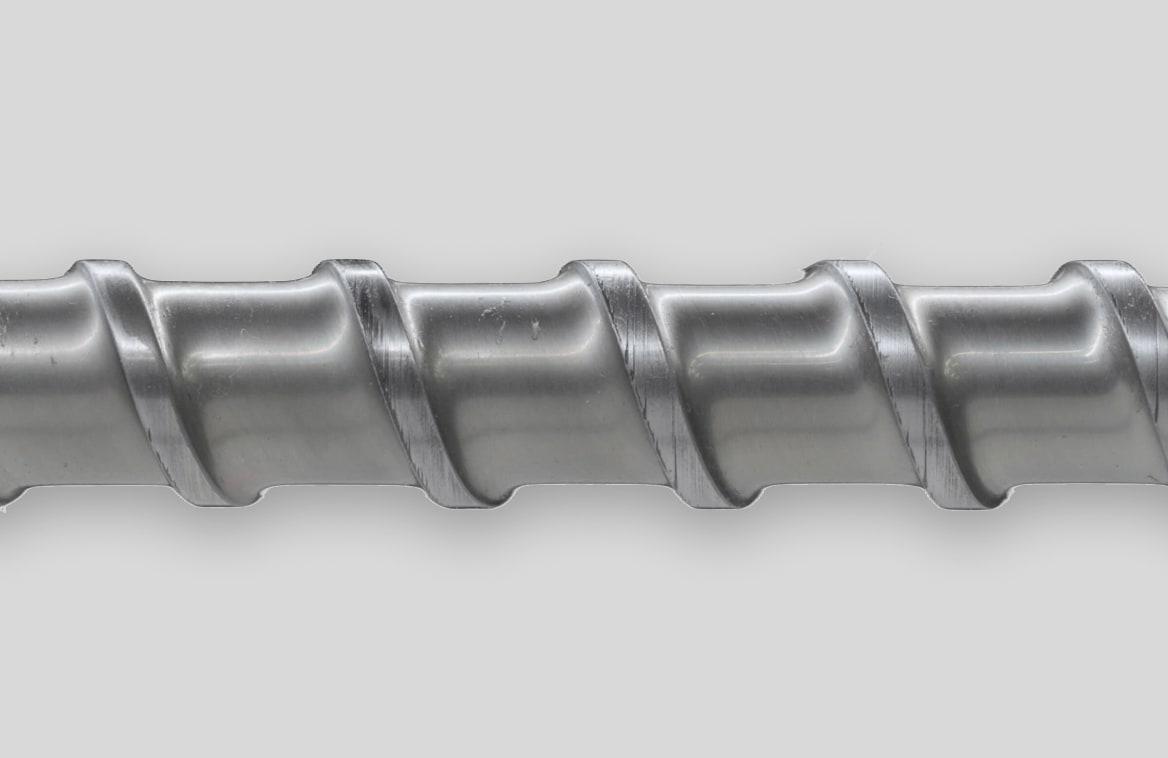

In plastic molding, including injection molding, pelletized resin is heated and melted inside a cylinder, then injected, filled, and extruded into a mold to produce products. It is common to switch between different resins and colors using a single molding machine, which often results in residual resin remaining inside the machine.

This residual resin can mix into the product as black, carbonized contaminants during the next molding process, causing defects such as black spots, contamination, and scorch marks. Additionally, the residual material can mix with the next processing resin, leading to changes in physical properties or color transfer, making it difficult to maintain consistent quality.Cases of Defects

-

Defects Caused by Residual ResinWhen resin used in previous production remains inside the machine, it can mix with the resin used in next processing resin, leading to color inconsistencies and performance degradation. This issue is particularly critical in the facilities where material changes are frequent.

-

Contaminant Defects such as Black Spots, Contamination, and Scorch MarksResidual resin can be carbonized inside the cylinder, and this carbonized resin can mix into the products, appearing as black spots or contaminants on the surface, which are major defects in the product's appearance. Additionally, when such defects occur, not only does it lead to a large number of defective products, but it also increases the workload for subsequent mold cleaning, screw removal for disassembly cleaning, and defect cause analysis, resulting in decreased production efficiency.

Countermeasures Using Purging Compound

One of the most effective methods for preventing defects is to use purging compounds to clean the residual resin inside the screw and barrel. Purging compounds are specially designed pellets developed to efficiently remove previous processing resin, carbonized material, and additives that remain inside the plastic molding machine.

-

Removal of Residual ResinBy using purging compound to remove residual resin, it is possible to prevent the previous processing resin from mixing with the next molded product, thereby suppressing color transfer and degradation of quality.

-

Prevention of Defects such as Black Spots, Contamination and Scorch MarksCarbonized material adhering to the screw can flake off and mix into the molded products, causing black spots and scorch marks. The excellent cleaning power of purging compounds can quickly remove such carbonized material, preventing issues in the injection molding machine.

-

Reduction of Maintenance and DowntimeBy regular cleaning with purging compounds, the frequency of screw removal can be reduced. This not only helps in preventing molding defects but also contributes to reducing maintenance work and downtime.

Experience the High-Performance Purging Compound, Asaclean!

Asaclean demonstrates its high cleaning power not only in injection molding but also in extrusion and blown film extrusion, preventing defects such as black spots, burns, and scorching. Additionally, its excellent low residual properties ensure that almost no residue remains after cleaning, allowing for a smooth transition to the next production. Furthermore, the high cleaning efficiency of Asaclean contributes to reducing material usage and work time, thereby lowering costs for materials, electricity, and labor. These benefits have earned Asaclean significant trust in the plastic industry, making it a key player in supporting high-quality and efficient production.