Main Materials Used for Organic Membranes

Organic membranes are generally made from high-polymer materials such as polyethylene (PE), polyvinylidene fluoride (PVDF), polytetrafluoroethylene (PTFE), polypropylene (PP), cellulose acetate (CA), polyacrylonitrile (PAN), polyimide (PI), polysulfone (PS), and polyethersulfone (PES). The choice of material depends on the required pore size and membrane manufacturing method.

Membrane properties such as hydrophilicity, hydrophobicity, heat resistance, chemical resistance, mechanical strength, and service life vary depending on the material and manufacturing method.

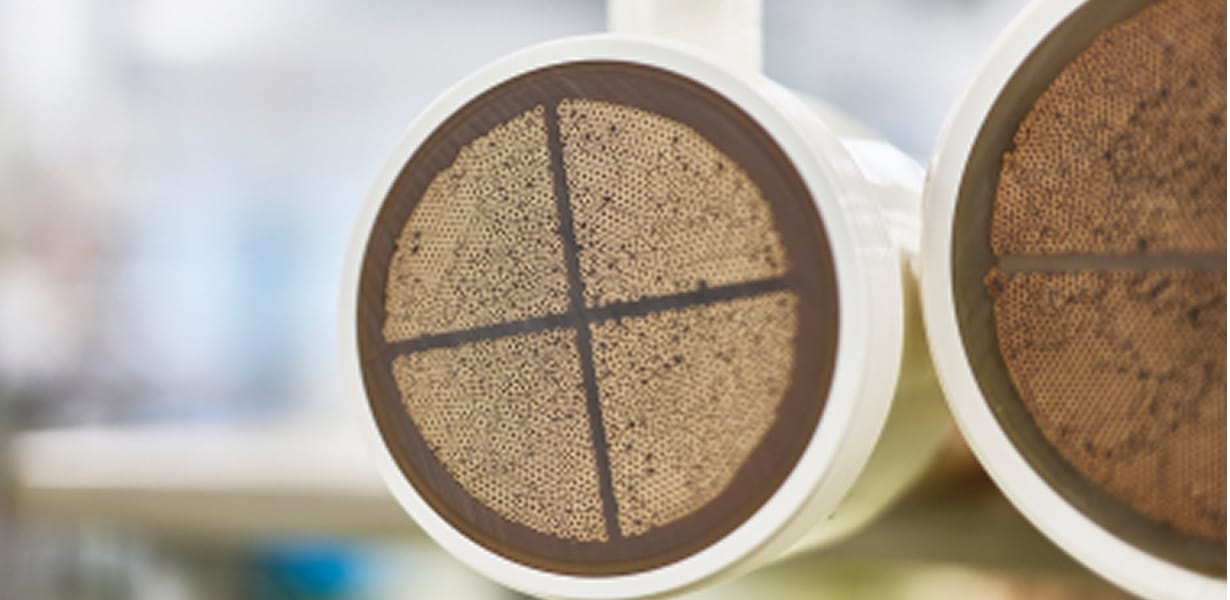

Main Materials Used for Inorganic Membranes

Inorganic membranes are generally made from materials such as ceramic, glass, and metal. Main materials include aluminum oxide (alumina Al2O3), zirconium oxide (zirconia ZrO2), titanium oxide (titania TiO2), stainless steel (SUS), and glass (SPG). As with organic membranes, membrane properties depend on the material and manufacturing method.

Check Out the High-Performance Hollow Fiber Membrane Lineup Now

Asahi Kasei's Microza® hollow fiber membranes for filtration and separation offer a diverse product lineup to suit various applications. The range includes high-precision MF (microfiltration) and UF (ultrafiltration) membrane modules in various materials, providing solutions for a wide range of filtration needs.