Enabling Mass Production of High-Purity Products

To address the challenges faced by major domestic chemical manufacturers B and C in deacidification and dealkalization of ground slurry, Asahi Kasei proposed an efficient desalination and purification system using Microza® UF membrane. Here is a specific case study.

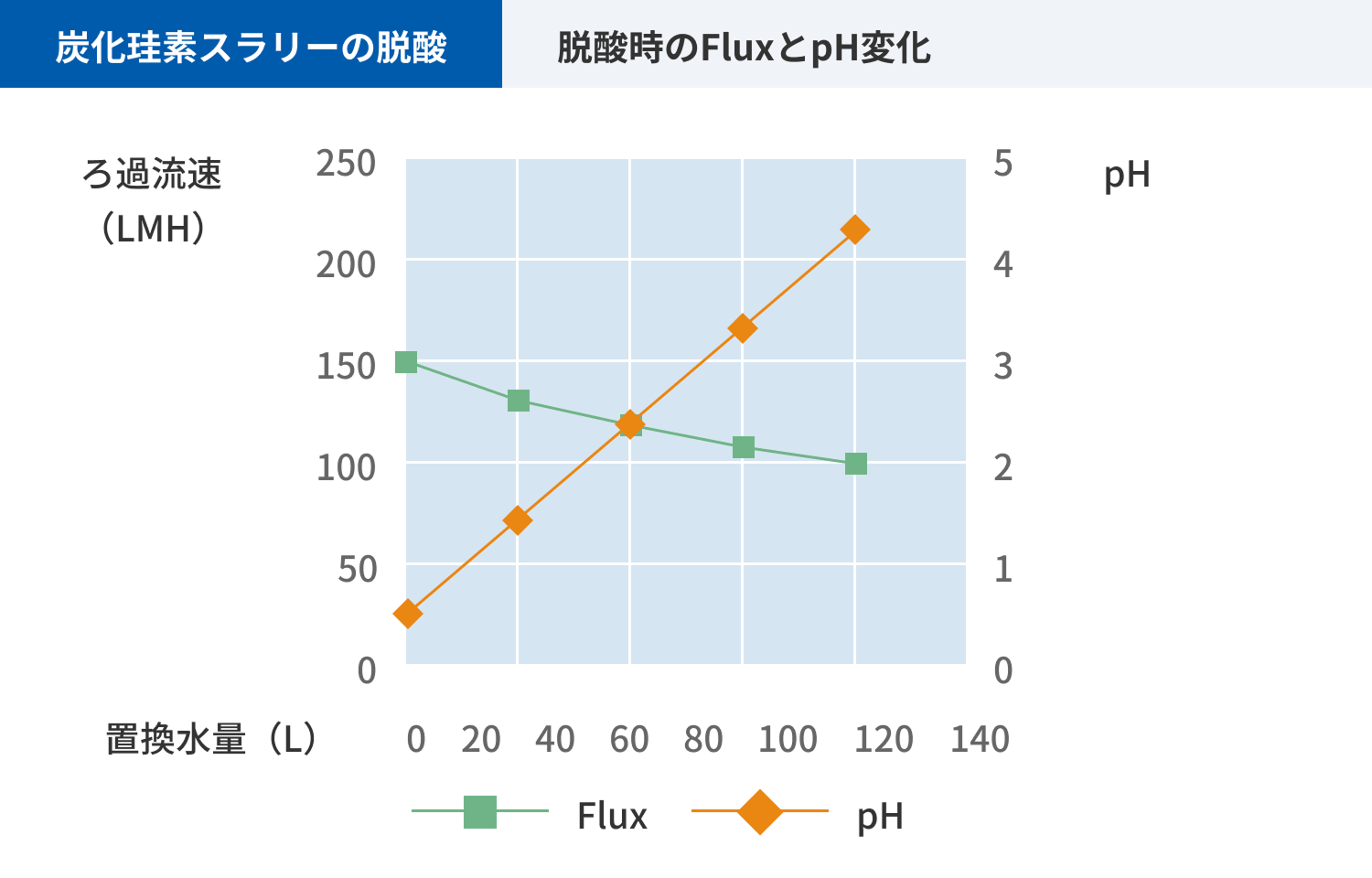

Case Study 1: Achieving Deacidification of Ground Slurry

At domestic chemical manufacturer B, a new product was developed that could not be sufficiently desalinated and purified by conventional methods, requiring advanced desalination. Asahi Kasei proposed an efficient and high-yield desalination and purification system using Microza® UF membrane, enabling mass production of high-purity products that was previously difficult.

-

Properties of the Target LiquidpH: 0.1, concentration: 20%, acid concentration: 3.6% (HCl), viscosity: 14 mPa·s, conductivity: 200 mS/cm.

-

Target ConditionpH 0.1 → pH 4

-

Test ConditionsTest solution volume: 10 L, pressure: Pi/Po = 120/80 kPa, backwash pressure: 140 kPa, backwash cycle: 20 min/20 sec, temperature: 30–35°C.

Case Study 2: Achieving Dealkalization of Ground Slurry

Domestic chemical manufacturer C introduced Microza® for dealkalization (desalination) of ground slurry. By implementing an efficient and high-yield desalination and purification system using Microza® UF membrane, mass production of high-purity products was achieved.

-

Properties of the Target LiquidpH: 13, concentration: 24%, alkali concentration: 1.6% (KOH), viscosity: 14 mPa·s, conductivity: 28 mS/cm.

-

Target ConditionpH 13→pH 10

-

Test ConditionsTest solution volume: 10 L, pressure: Pi/Po = 120/80 kPa, backwash pressure: 140 kPa, backwash cycle: 20 min/20 sec, filtration temperature: 20–25°C.