High-Performance UF Membranes for Pharmaceutical and Food Industries

The Industrial Process UF AP/SP Series has a proven track record in the concentration and purification of enzymes, proteins, and food ingredients. Asahi Kasei's proprietary double-skin structure achieves both high strength and filtration performance. The use of highly hydrophilic and chemically resistant membrane materials ensures reliable quality for pharmaceutical and food applications requiring strict hygiene standards.

Details of Industrial Process UF AP/SP Series

Features of Industrial Process UF AP/SP Series

A double skin structure with separation-function skin layers on both inner and outer surfaces ensures high filtration reliability and strength (Learn More Here).

The AP Series uses highly hydrophilic polyacrylonitrile (PAN) material to prevent contamination by proteins and oils, allowing easy cleaning with low-concentration chemicals.

The SP Series uses polysulfone material with high heat and chemical resistance, maintaining high safety even under demanding conditions.

Solutions for Industrial Process UF AP/SP Series

Application Fields by Industry

Food: Contributes to improved productivity in separation and filtration processes in the food industry through both software and hardware approaches (Learn More Here).

Pharmaceuticals: Improved yield and productivity for target substances (antibodies, proteins, vaccines, enzymes, etc.) (Learn More Here)

Application Fields by Use

Concentration and Purification of Enzymes and Protein Preparations

Broth Purification (Sterilization/Protein Removal)

Food Purification (Sterilization/Protein Removal) and Concentration

Concentration and Purification of Colloidal Substances

Recovery of Valuable Substances from Other Aqueous Solutions

Product Specifications of Industrial Process UF AP/SP Series

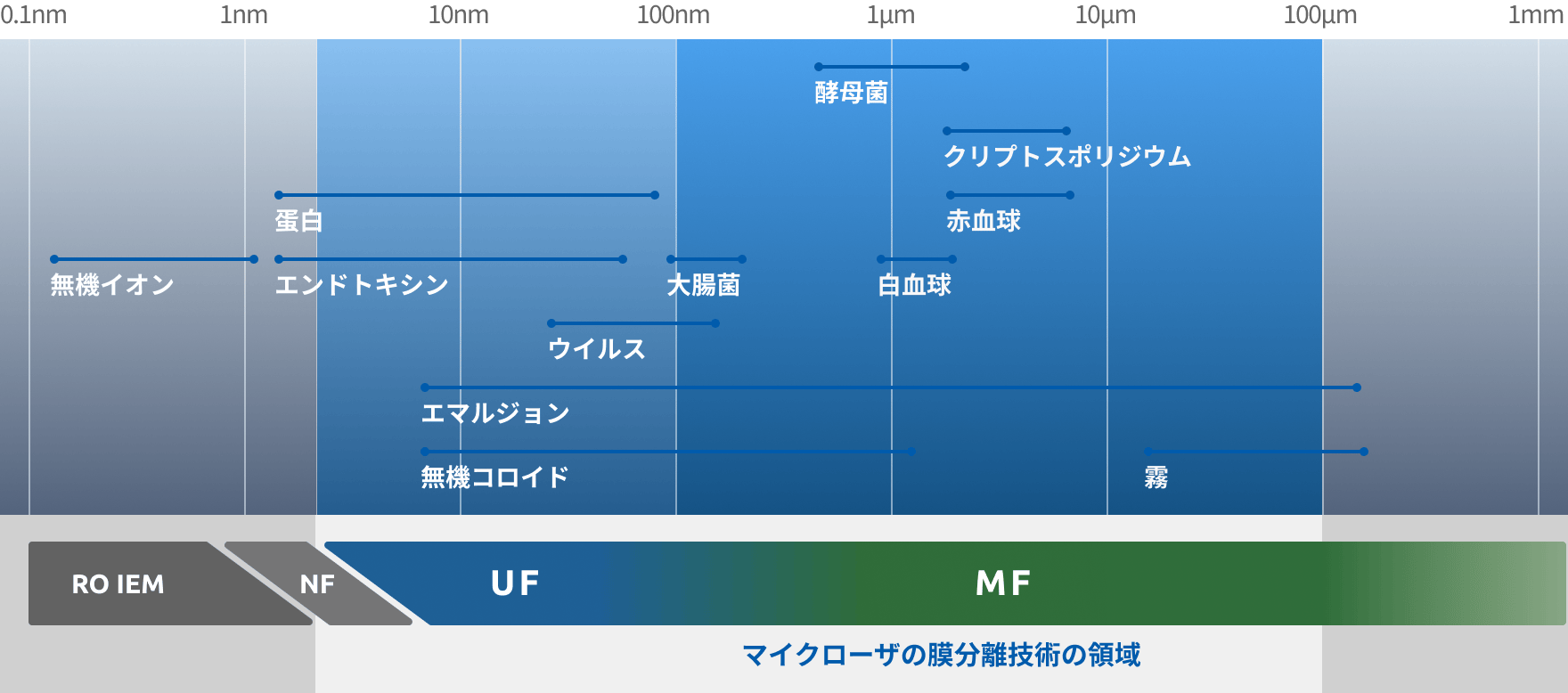

Filtration range of UF membranes capable of removing viruses and macromolecules

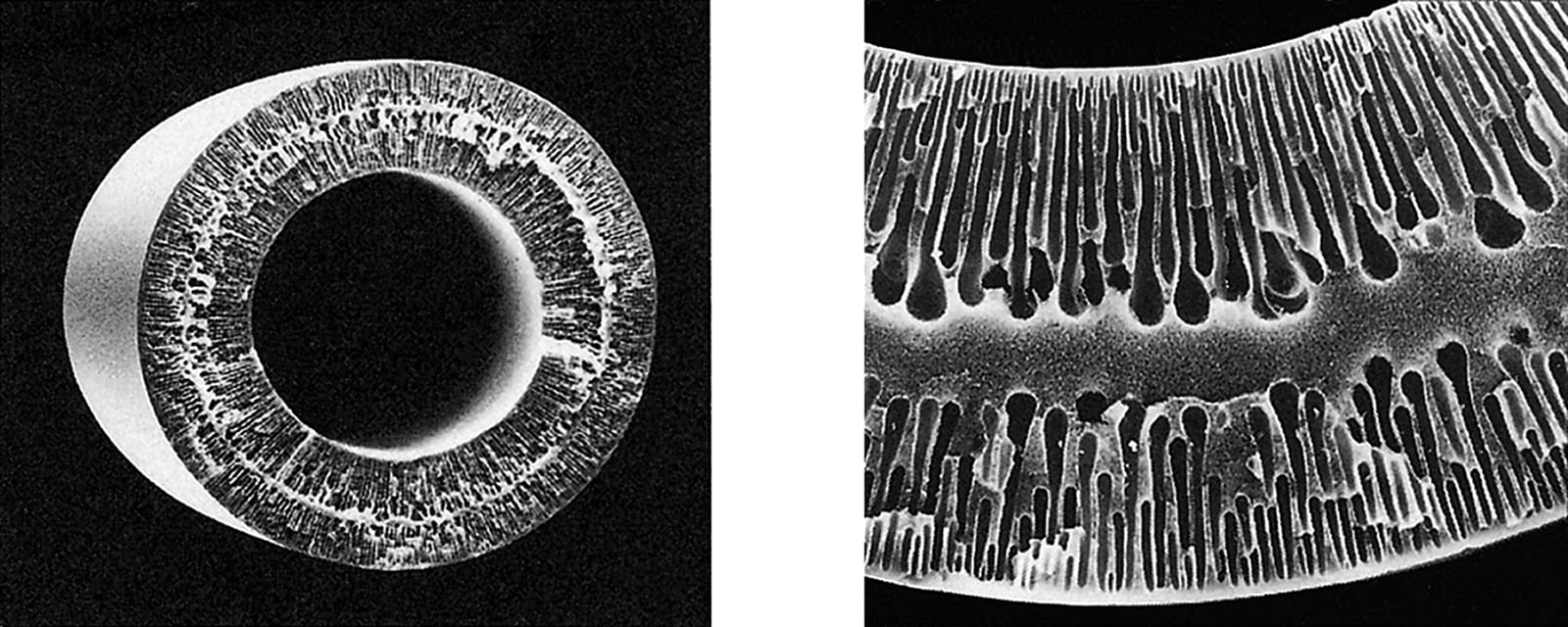

Electron Micrograph of UF Membrane

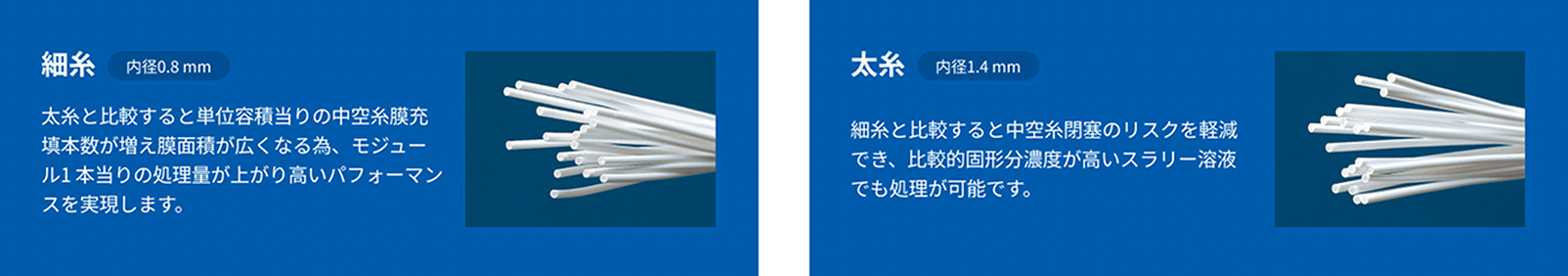

Membrane Inner Diameter

Datasheet - AP Series

| Model | AP Series | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| AIP-3013D | ACP-3013D | ACP-3053D | AHP-3013D | AOP-3013 | AIP-5013 | ACP-5013 | AOP-5013 | ||

| Material | Hollow Fiber Membrane | Polyacrylonitrile | |||||||

| Module Case | Polysulfone | ||||||||

| Specification | Membrane I.D. (mm) | 0.8 | 1.4 | 0.8 | 0.75 | 0.8 | 0.75 | ||

| Effective Membrane Area (m2) | 4.7 | 3.1 | 5.2 | 11.8 | 11.0 | 11.4 | |||

| Performance | Nominal Molecular Weight Cut-Off | 6,000 | 13,000 | 50,000 | 80,000 | 6,000 | 13,000 | 80,000 | |

| Initial Permeate Flow Rate*1 (L/hour at 100 kPa) | 460 | 750 | 360 | 2,250 | 1,800 | 1,050 | 1,750 | 3,500 | |

| Operating Conditions | Max. Feed Pressure (kPa) | 500 | 400 | 500 | 300 | ||||

| Max. Transmembrane Pressure (kPa) | 300 | 200 | 300 | ||||||

| Max. Operating Temperature (°C) | 50 | ||||||||

| Operating pH Range | 2−10 | ||||||||

| Module Dimensions (mm) | 1,129 L x 89 φ | 1,172 L x 140 φ | |||||||

| Size | 3 inch | 5 inch | |||||||

| * Indicates the initial filtrate volume when filtering clarified water at 25 °C and 100 kPa. | |||||||||

Datasheet - SP Series

| Model | SP Series | |||||||

|---|---|---|---|---|---|---|---|---|

| SEP-2013 | SIP-2013 | SLP-2053 | SEP-3013 | SIP-3013 | SLP-3053 | |||

| Material | Hollow Fiber Membrane | Polysulfone | ||||||

| Module Case | ||||||||

| Specification | Membrane Inner Diameter (mm) | 0.8 | 1.4 | 0.8 | 1.4 | |||

| Effective Membrane Area (m2) | 1.0 | 0.6 | 4.7 | 4.5 | ||||

| Performance | Nominal Molecular Weight Cut-Off | 3,000 | 6,000 | 10,000 | 3,000 | 6,000 | 10,000 | |

| Initial Permeate Flow Rate**1 (L/hour at 100 kPa) | 130 | 200 | 150 | 650 | 1,000 | 1,500 | ||

| Operating Conditions | Maximum Feed Pressure (kPa) | (0–50°C) | 500 | 300 | 500 | 300 | ||

| (51–80°C) | 300 | 200 | 300 | 200 | ||||

| (81–90°C) *2 | 200 | 100 | 200 | 100 | ||||

| Maximum Transmembrane Pressure (kPa) | (0–50°C) | 300 | 300 | 300 | 300 | |||

| (51–80°C) | 200 | 200 | 200 | 200 | ||||

| (81–90°C) *2 | 100 | 100 | 100 | 100 | ||||

| Maximum Operating Temperature (°C) | Normal Use | 80 | 80 | 80 | 80 | 80 | 80 | |

| Hot Water Sterilization | 90 | 95 | 90 | 90 | 95 | 90 | ||

| Allowable pH Range | 1-14 | |||||||

| Module Dimensions (mm) | 552L x 60φ | 1,129L x 89φ | ||||||

| Size | 2 inch | 3 inch | ||||||

| *1: Indicates the initial filtrate volume when filtering clarified water at 25 °C and 100 kPa. *2: SIP-3013 and SIP-2013 can be used at temperatures up to 95 °C. | ||||||||