Streamlining the Colloidal Silica Concentration Process

Microza® from Asahi Kasei provided a solution to the concentration challenges faced by chemical manufacturer E in Japan. This case demonstrates how the system enabled an efficient process and high concentration ratio.

Achieving High Concentration of Colloidal Silica

Company E had been exploring methods to increase the concentration level of colloidal silica. Asahi Kasei proposed a Microza®-based filtration system, which successfully achieved a high concentration ratio.

-

Properties of the Target LiquidpH: 10, Concentration: 4%, Viscosity: 1 mPa·s

-

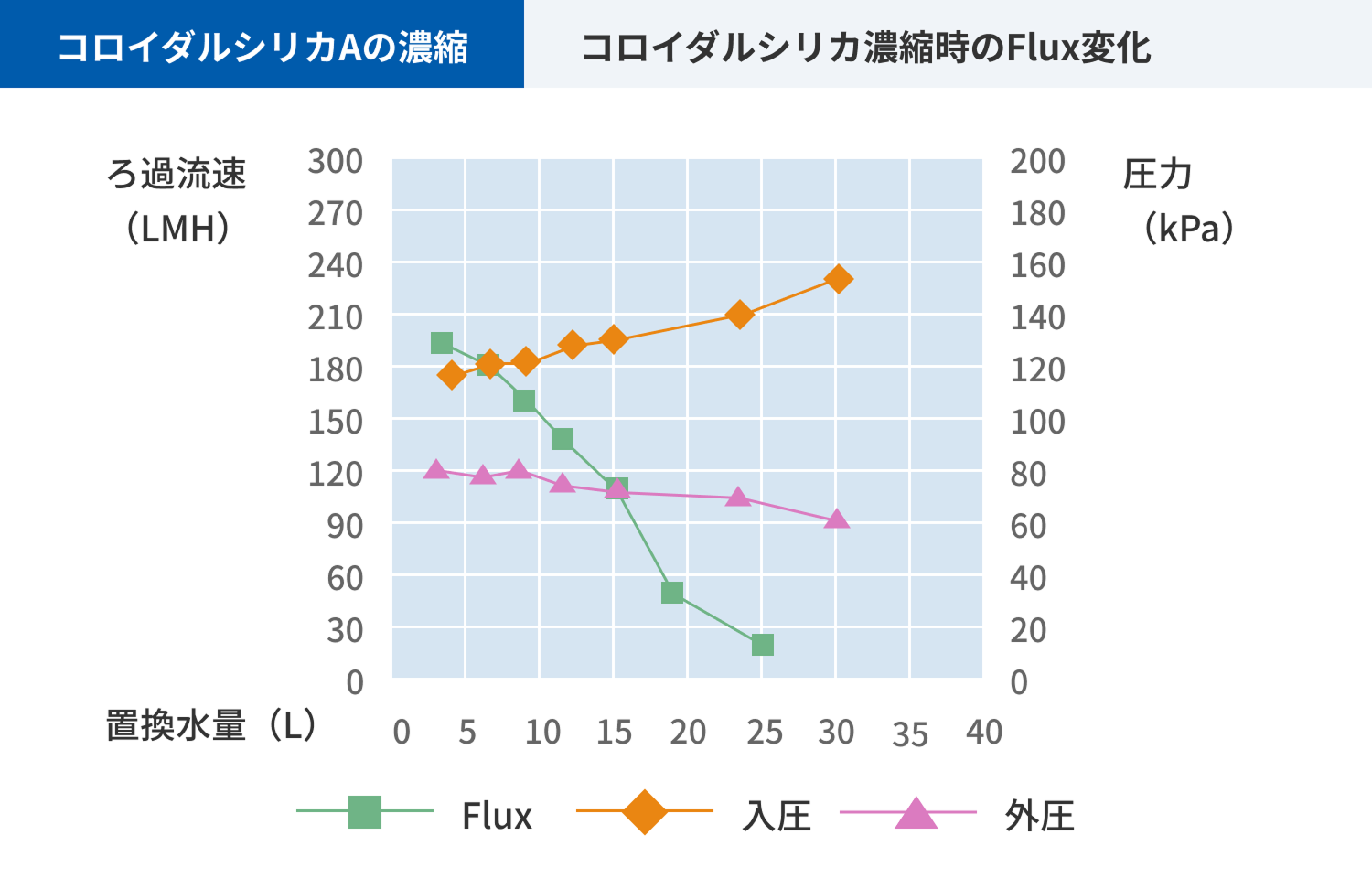

Target Concentration10× (3% → 30%)

-

Test ConditionsTest liquid volume: 40 kg, Pressure: Pi/Po = 120/80 kPa, Backwash pressure: 140 kPa, Backwash cycle: 20 min / 20 sec, Filtration temperature: 70°C