Achieving Both Improved Separation Accuracy and Streamlined Concentration Process

Chemical manufacturer F faced challenges in impurity removal and concentration processes for pigment dispersions. Microza® streamlined the entire concentration process, achieving targets without compromising accuracy.

Streamlining the Pigment Concentration Process

Company F was seeking a system to remove impurities from pigment dispersions and concentrate them to a specific level. Asahi Kasei proposed an efficient and precise filtration system using Microza®, streamlining the pigment concentration process.

-

Properties of the Target LiquidpH: 9, concentration: 10%, viscosity: 2 mPa·s.

-

Targeted Condition10-fold increase (3%→30%)

-

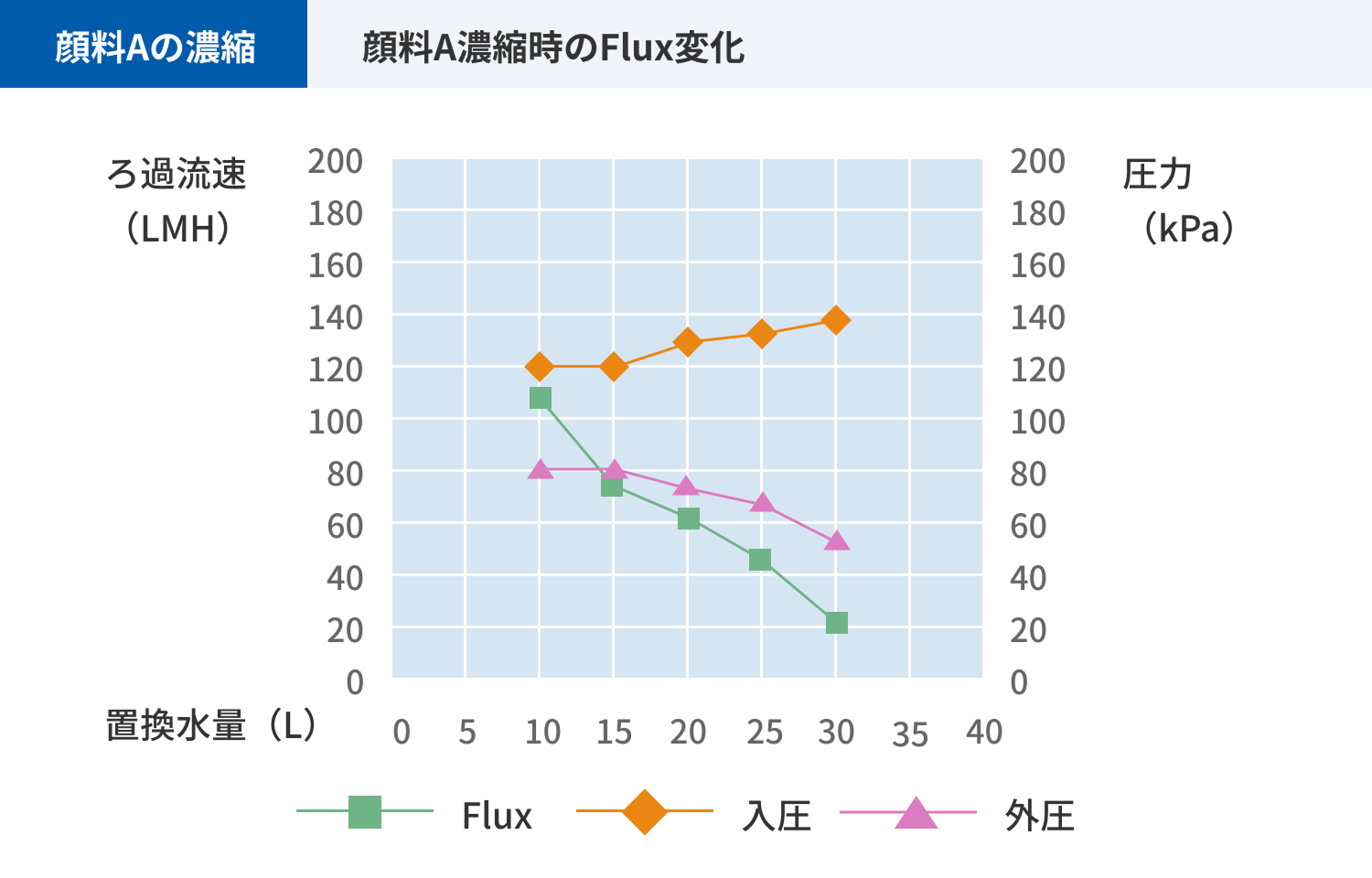

Test ConditionTest solution volume: 18 kg, pressure: Pi/Po = 120/80 kPa, backwash pressure: 140 kPa, backwash cycle: 20 min/10 sec, filtration temperature: 25°C.