Supporting Semiconductor Quality at Its Core

Microza® provides high-quality ultrapure water solutions required for semiconductor manufacturing. Its double-skin structure enables precise removal of particles and other impurities, while the dual-end collection structure reduces pressure loss for energy savings.

High-Quality Ultrapure Water Required for Semiconductor Manufacturing

In semiconductor manufacturing processes, the purity of ultrapure water determines product quality. The presence of impurities increases the risk of defects, so it is necessary to remove particles and other contaminants.

Microza® is a hollow fiber membrane product that integrates advanced technologies to address these ultrapure water production challenges. It is used in numerous semiconductor plants around the world.

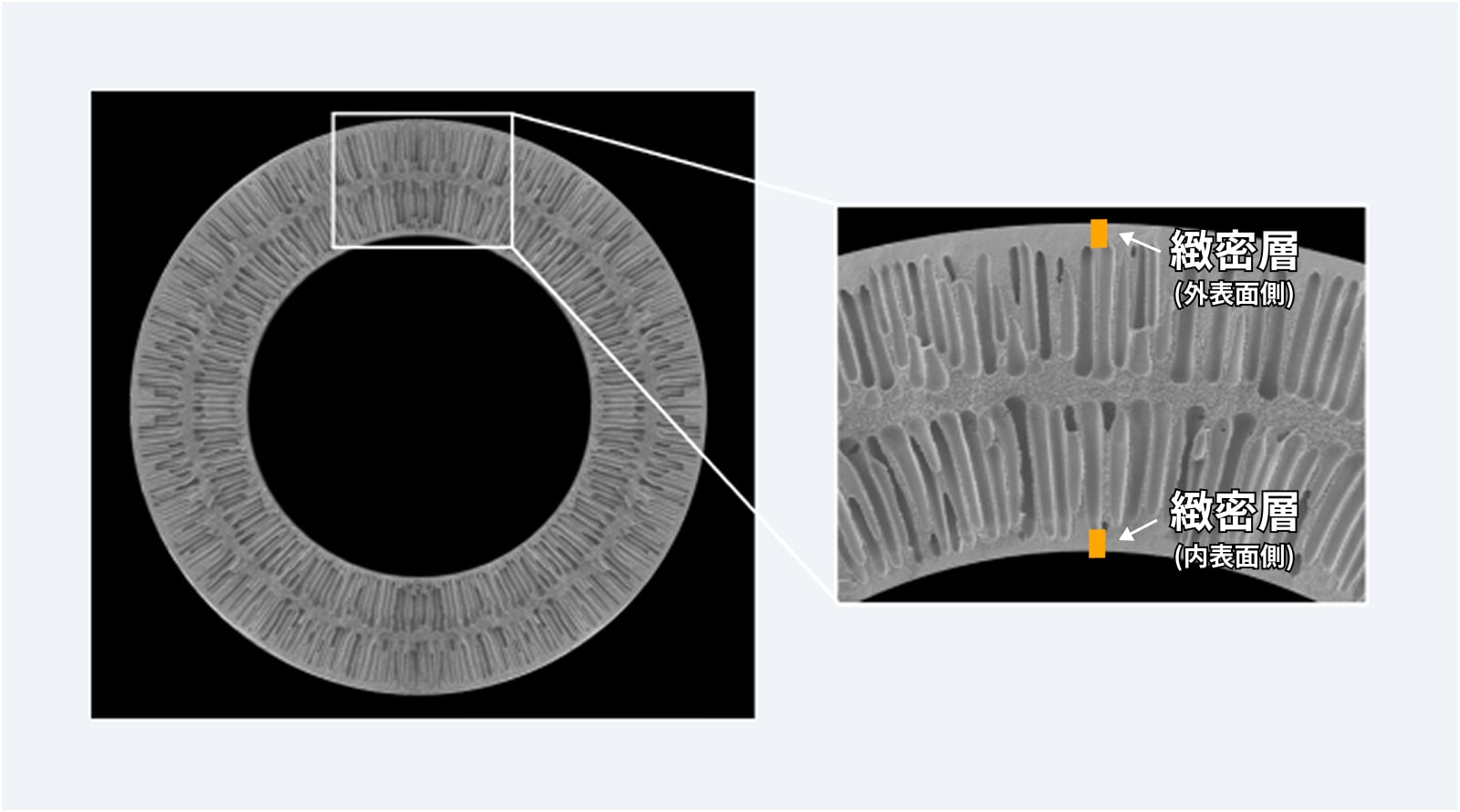

Robust Fine Particle Removal Performance (Double-Skin Structure)

Microza® uses a unique "double-skin structure." This structure forms dense layers on both the inner and outer surfaces of the hollow fiber membrane, achieving high separation performance and excellent durability.

Learn More About Microza® Technologies Such as the Double-Skin StructureReduced Internal Module Pressure Loss (Dual-End Collection Structure)

Microza® employs a proprietary dual-end collection structure. This design significantly reduces internal pressure loss within the module.

In addition, reduced internal differential pressure allows water to be distributed more evenly, minimizing dead space and achieving high cleanliness inside the module.