With a Simple Process

Improved Productivity in Bacterial Collection and Washing

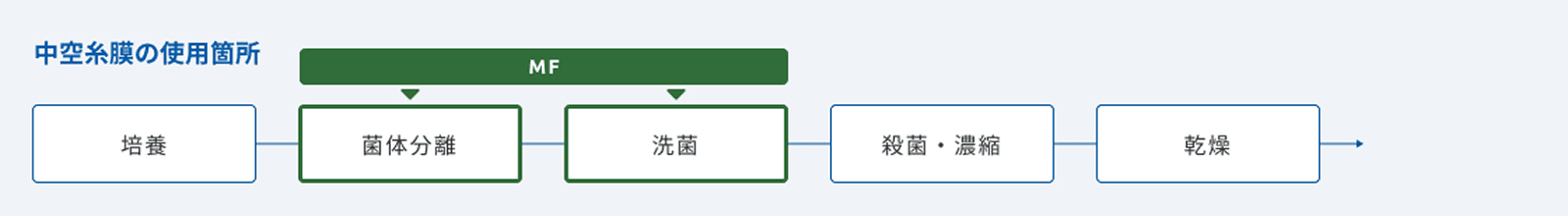

This case introduces food ingredient manufacturer A, which improved productivity by introducing Microza® MF membranes in the collection and washing processes required after lactic acid bacteria cultivation. The ability to efficiently remove low-molecular components from the medium and improve recovery capacity in limited installation space was highly evaluated. Ease of scale-up was also a key factor in adoption.

Improved Cell Recovery Efficiency and Shortened Processing Time

When recovering cells while removing low-molecular components from the medium by adding water, Company A faced the challenge that processing time was long with existing equipment, limiting production volume. By introducing Microza® MF membranes with large membrane area and high recovery rate, Company A succeeded in increasing processing capacity even in limited installation space.

Achieve Scale-Up with Microza® MF Membranes

Initially, food ingredient manufacturer A used a small centrifuge for recovery but needed to scale up. Scaling up with centrifuges would require high equipment costs and securing space for larger machines. By adopting Microza® MF membranes, Company A achieved more cost-effective and space-saving scale-up.