Optimizing Ultrapure Water Production and Water Reuse

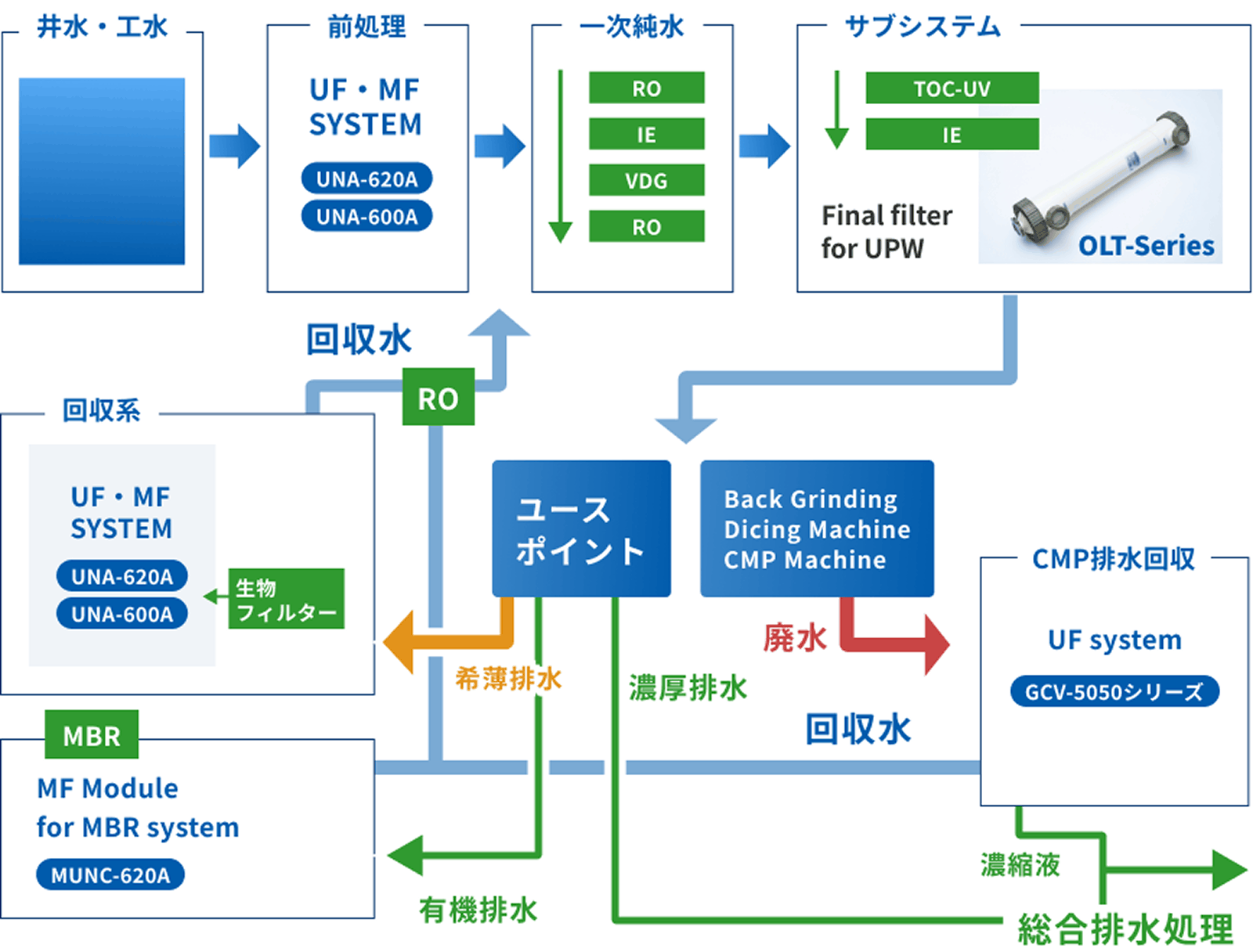

Microza® contributes to the electronics industry by supplying high-purity ultrapure water and enabling water recycling. Microza® for ultrapure water production features a double-skin structure and dual-end collection structure, achieving both water purification and cost reduction. It is also used for wastewater recycling, supporting effective use of water resources.

High Particle Removal Performance Essential for Ultrapure Water Production

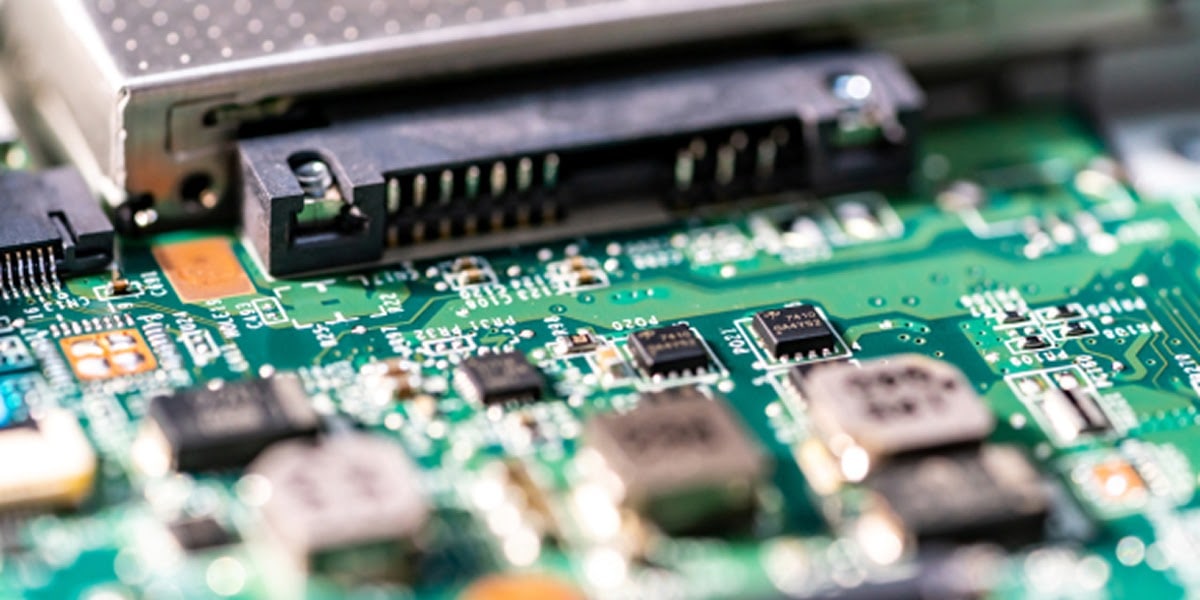

Ultrapure water used in semiconductor manufacturing processes requires extremely high purity. However, contamination by particles and other impurities can reduce semiconductor yield and affect product quality. Similarly, strictly controlled ultrapure water is essential in LCD manufacturing processes.

To address these challenges, Microza® employs a unique double-skin structure that delivers robust particle removal performance. This enables efficient filtration of fine particles and unwanted substances, reducing impurities in ultrapure water.

Learn More About Microza® Technologies Such as the Double-Skin StructureReducing Module Pressure Loss and Ultrapure Water Production Costs

Microza® adopts a dual-end collection structure. By optimizing water flow within the module, it significantly reduces pressure loss, enabling stable operation and energy-efficient performance.

In addition, reduced internal differential pressure allows water to be distributed more evenly, minimizing dead space and achieving high cleanliness inside the module.

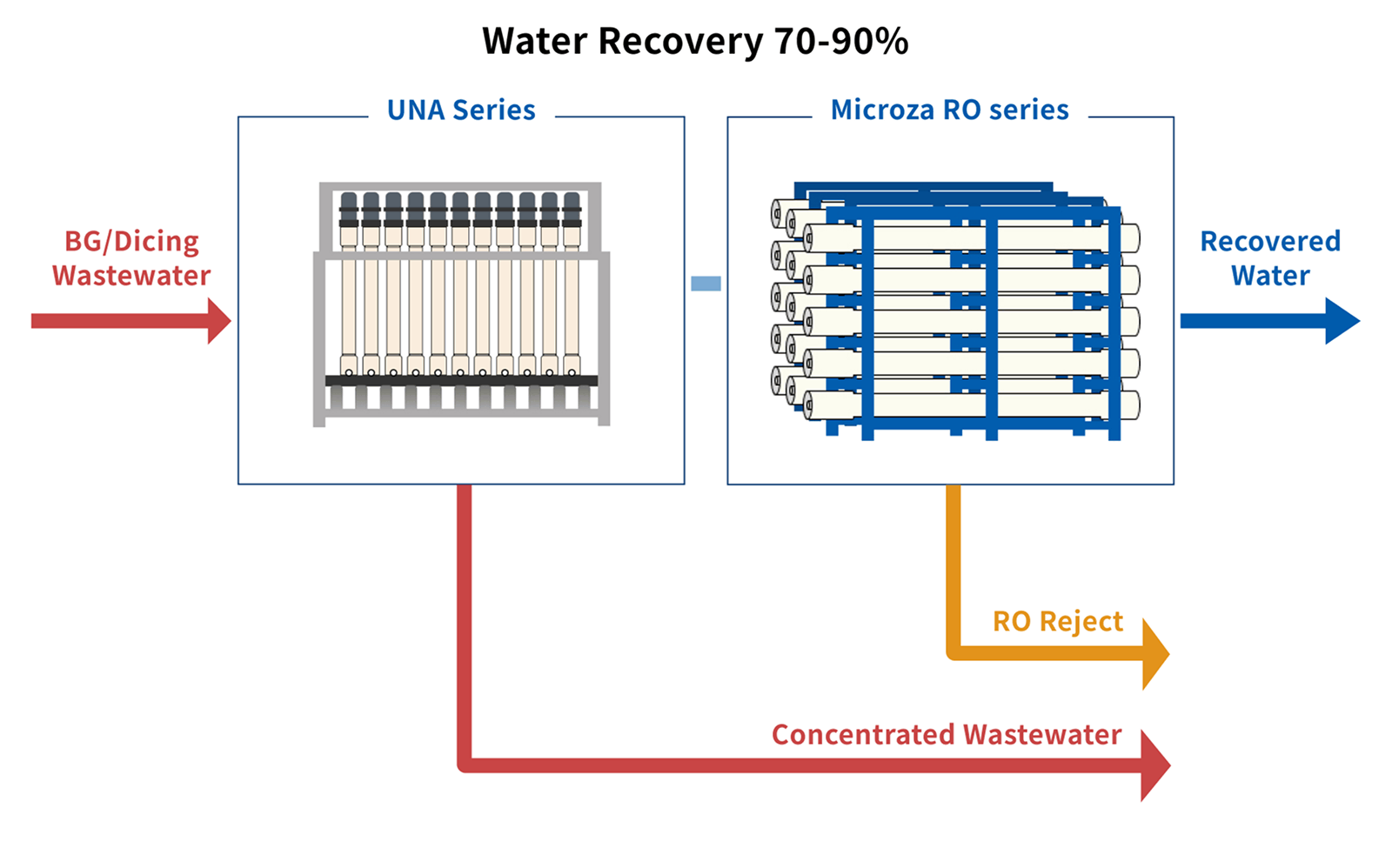

Reuse of Wastewater from Semiconductor Manufacturing to Reduce Water Consumption

Effective use of water resources is a critical issue in the semiconductor industry, where reduction of wastewater is increasingly required. Microza® enables wastewater reuse in semiconductor manufacturing by leveraging its high-performance removal capabilities. For example, a semiconductor manufacturer in China introduced the UNA-620A into its production line to reuse wastewater generated during backgrinding (BG) and dicing processes. Even wastewater with turbidity exceeding 1,000 NTU can be reused through simple UF filtration.