Innovative Desalting Purification System for Improved Processing Efficiency

Company A, a domestic chemical manufacturer, significantly shortened the time to reach the target conductivity with a groundbreaking process replacing gravity separation. This introduces a process made more efficient by Microza®.

Improved Processing Efficiency with a New Separation Process

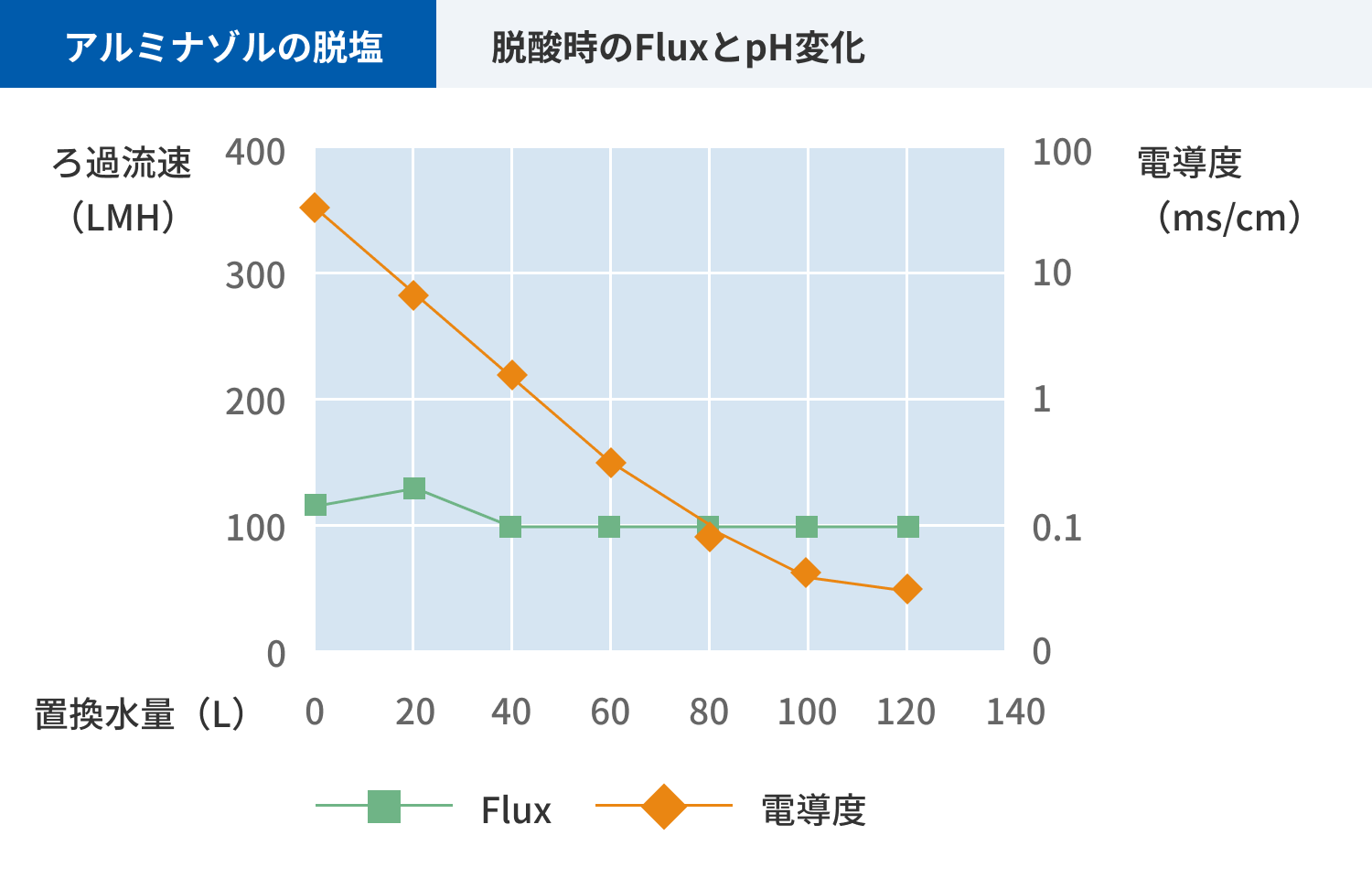

Company A, a domestic chemical manufacturer, previously used gravity separation for alumina sol desalting, but due to low processing efficiency, considered a new separation process. Asahi Kasei proposed an efficient desalting purification system using Microza® UF membrane, which shortened the time required for desalting. The results are shown in the figure below.

-

Properties of the Target LiquidpH: 9, concentration: 6%, salt concentration: NH4Cl = 3%, viscosity: 100 mPa·s, conductivity: 40 mS/cm.

-

Target conductivityTest solution volume: 10 L, pressure: Pi/Po = 130/70 kPa, backwash pressure: 150 kPa, backwash cycle: 20 min/20 sec, filtration temperature: 30–35°C.