Simplifying Processes to Streamline Food Manufacturing

Conventional filtration technologies present significant barriers to productivity and quality improvement due to complex separation, purification, and concentration processes. Microza® simplifies these processes, providing an innovative solution that enables anyone to achieve stable quality and efficiency. It also helps reduce energy costs and waste.

Simplifying Processes to Improve Productivity

In conventional filtration technologies, separation, purification, and concentration are divided into multiple steps, requiring significant effort for preparation, cleaning, and maintenance of each filtration process. In addition, operator-dependent variability in purity and yield has been a major challenge.

With Microza®, separation, purification, and concentration can be completed in a single process. As there is no need for separate operations at each stage, night-time operation is possible, allowing high productivity even in facilities with limited personnel. In addition, by eliminating the need for filter aids that require skilled adjustment, consistent filtration performance can be achieved regardless of the operator, reducing operator dependency.

Reducing Stress on Microorganisms and Target Substances to Improve Production Efficiency

In food production utilizing microorganisms, there is a challenge where physical stress during purification processes reduces the survival rate of cells and live microorganisms, resulting in decreased production efficiency and yield. In particular, processes such as cross-flow membrane separation can cause damage to live cells and enzymes due to high circulation flow rates, hindering efficiency improvements.

Microza® provides effective cross-flow performance even at low linear velocities, enabling separation and concentration with minimal stress on target substances. Physical damage to cells and enzymes can be minimized. Additionally, operation at low linear velocity contributes to energy cost reduction. Introducing Microza® reduces stress on microorganisms and target substances while significantly improving yield and maintaining product quality.

Reduce Impurity Risk and Improve Quality with High Separation Precision

In the food sector, where quality standards are becoming increasingly stringent each year, existing equipment alone cannot completely prevent the inclusion of unwanted substances, making it difficult to improve final product quality.

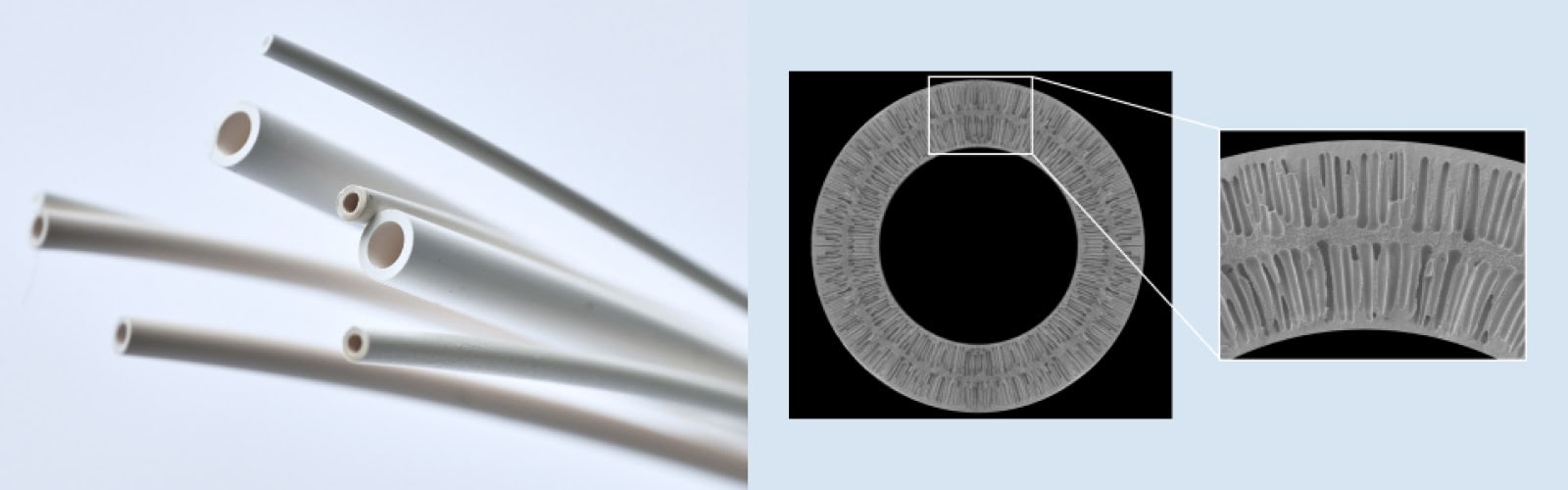

Microza® UF membranes (ultrafiltration membranes) effectively address this issue. Featuring a double-skin structure with separation layers on both the inside and outside of the hollow fiber, they prevent impurity intrusion while minimizing the risk of target substance leakage. In addition, Microza® supports backpressure cleaning, which reverses liquid flow from the permeate side (secondary side) to the feed side (primary side), helping maintain consistent filtration performance.

Learn More About Microza® Technologies Such as the Double-Skin StructureReduce Waste and Energy Costs for a Sustainable Process

Many food manufacturers face increasing costs and energy consumption in separation processes, as well as challenges in handling large volumes of waste generated during filtration. In particular, conventional methods using filter aids result in rising purchase and disposal costs, and the environmental impact of industrial waste disposal is a significant concern. Furthermore, many companies are considering not only disposal but also the possibility of resource recovery from these materials.

Microza® offers a solution that requires no filter aids and enables efficient separation at low linear velocity. Eliminating the need to purchase and dispose of filter aids significantly reduces waste and disposal costs while lowering energy consumption. This not only reduces overall process costs but also facilitates resource recovery efforts, enhancing environmental performance.

Solve Challenges Across All Food Sectors with a Diverse Product Lineup

In food manufacturing, it is not uncommon for companies to be unsure which separation technology is best suited to their products and production conditions when introducing new equipment.

To address this challenge, Microza® offers a wide range of membrane materials, separation precision levels, and hollow fiber inner diameters to support various food applications including sweeteners, alternative proteins, honey, amino acids, sake, health food ingredients, enzymes, soy sauce, lactic acid bacteria, algae, cultured meat, and a wide variety of extracts.

Achieve Smooth Scale-Up

When considering new equipment investment or replacement of aging facilities, it is challenging to assess commercial-scale adaptability based solely on laboratory-scale performance using centrifuges or similar devices.

Microza® adopts a scalable design based on membrane module units. This allows smooth scale-up from small-scale testing to commercial-scale production based on verified test results.

Maximize Efficiency in Limited Space

Compared to other filtration technologies such as tubular and ceramic membrane modules, hollow fiber membrane modules feature a larger membrane area per unit volume. This design enables installation in limited spaces and allows for much more compact system construction compared to conventional modules. Additionally, efficient membrane configuration helps reduce power consumption during operation, enabling energy-efficient system performance.