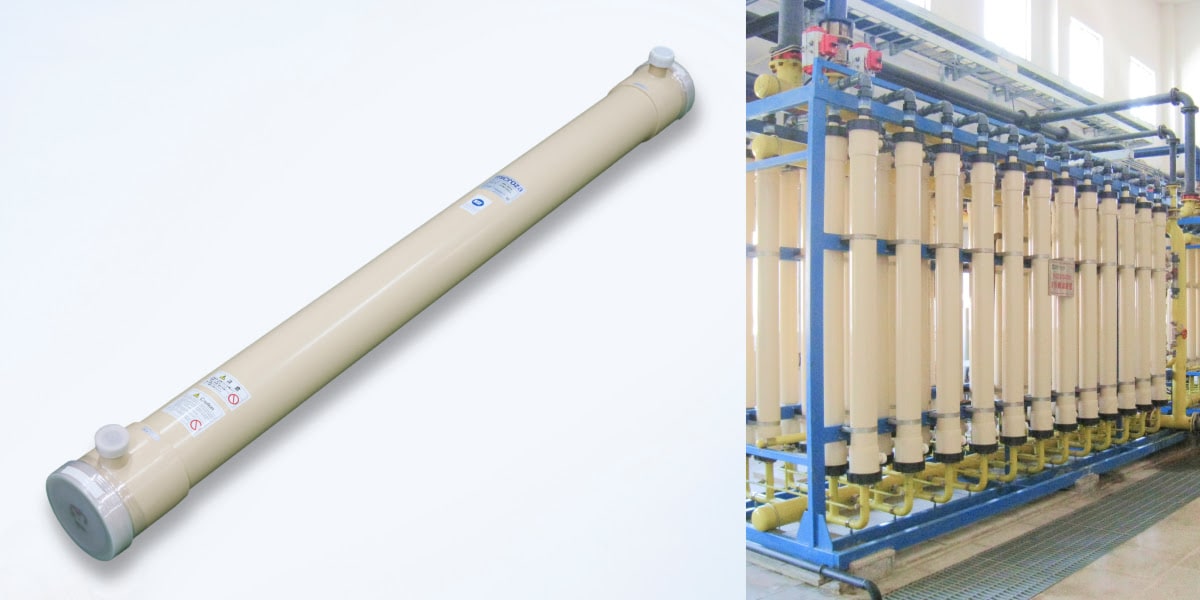

Durable Hollow Fiber Membranes for Diverse Water Treatment Needs

The UNA Series is a PVDF hollow fiber membrane module that meets a wide range of water treatment needs, from waterworks to industrial wastewater recycling. Asahi Kasei's manufacturing technology using the TIPS method provides high mechanical strength and chemical resistance. Stable operation is possible even under harsh conditions, contributing to reduced operating and investment costs.

Details of Water Treatment Process UNA Series

Features of Water Treatment Process UNA Series

High mechanical strength and chemical resistance achieved through manufacturing technology using the TIPS method.

Compatible with various conditions, including sodium hypochlorite (up to 5,000 mg/L), sodium hydroxide (up to 4%), hydrochloric acid, sulfuric acid, and oxalic acid (up to 10%).

High durability and long service life reduce replacement frequency and contribute to lower operating costs.

Stable operation enables efficient water treatment and reduces capital investment costs.

Equipment Installation Example

Solutions for Water Treatment Process UNA Series

Application Fields by Industry

Water Supply and Sewerage

Industrial Water

Industrial Wastewater

Water Recycling

Application Fields by Use

Water Supply for Industrial Complexes

Reuse of Effluent at Sewage Treatment Plants

Industrial wastewater from power plants, steel, paper, food, oil and gas, and pharmaceutical industries

Main Product Specifications of Water Treatment Process UNA Series

| Model | Type | Surface Area (m2/ft2) | Length mm/in |

|---|---|---|---|

| UNA-600A | Pressurized Type | 23 / 247 | 1314 / 51.7 |

| UNA-620A | Pressurized Type | 50 / 538 | 2418 / 95.2 |

| UNA-620AB | Pressurized Type | 65 / 699 | 2418 / 95.2 |

| UNA-620C | Pressurized Type | 50 / 538 | 2418 / 95.2 |

| UNA620A-ADA | Pressurized Type | 50 / 538 | 2418 / 95.2 |

| UNA620A-DCA | Pressurized Type | 99 / 1065 | 2300 / 90.5 |

| UHS-620A2 | Submerged Type | 50 / 538 | 2209 / 87.0 |