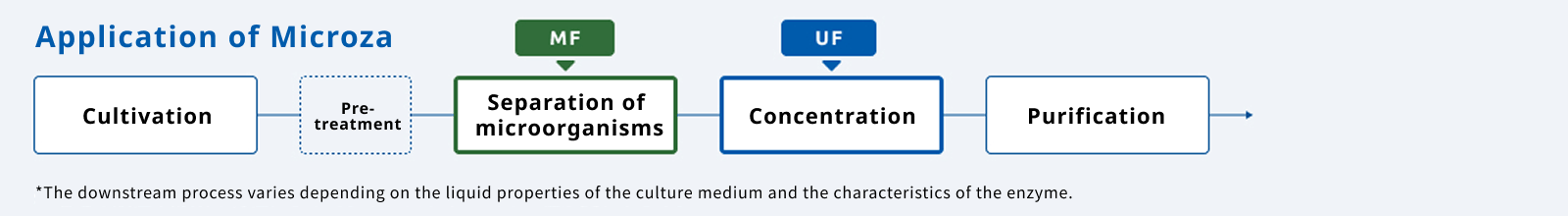

Reduce Labor and Waste Through Membrane-Based Purification

A domestic food ingredient manufacturer, Company B, introduced Microza® into the downstream process of enzyme production. This section introduces the efficiency improvements in enzyme production achieved with Microza®.

Streamlined Cell Collection and Washing: MF Membranes Suitable for High-Solids Media

Various separation technologies are used for cell separation after microbial fermentation, depending on the liquid properties. One typical method is diatomaceous earth filtration using filter aids. Company B, a domestic food ingredient manufacturer, used diatomaceous earth filtration for enzyme purification but faced multiple challenges such as the burden of applying diatomaceous earth, waste disposal, and improving the work environment.

Company B introduced Microza® MF membranes using membrane filtration. Since Microza® does not require filter aids, it enabled significant waste reduction and simplification of work processes, which were difficult with conventional methods. Microza® also offers MF membranes with large inner diameters, allowing smooth filtration even with high-solids content.

After switching to Microza®, Company B still needed to purify multiple enzymes on a single line. With support from Asahi Kasei, they carefully verified that all enzymes could be purified without issues and successfully established an appropriate membrane filtration process.

Enzyme Concentration and Recovery with UF Membranes: Broad Support with Hydrophilic Materials

Membrane methods are also effective in enzyme concentration processes. Selecting the right membrane performance is crucial to achieve high concentration rates while ensuring enzyme stability and quality.

In this case, a highly hydrophilic polyacrylonitrile UF membrane was selected. This enables efficient enzyme recovery and separation of unwanted components, resulting in higher-purity enzymes.

Microza® has a proven track record in processes combining MF and UF for both commercial enzyme production and in-house enzyme manufacturing, supporting a wide range of applications.