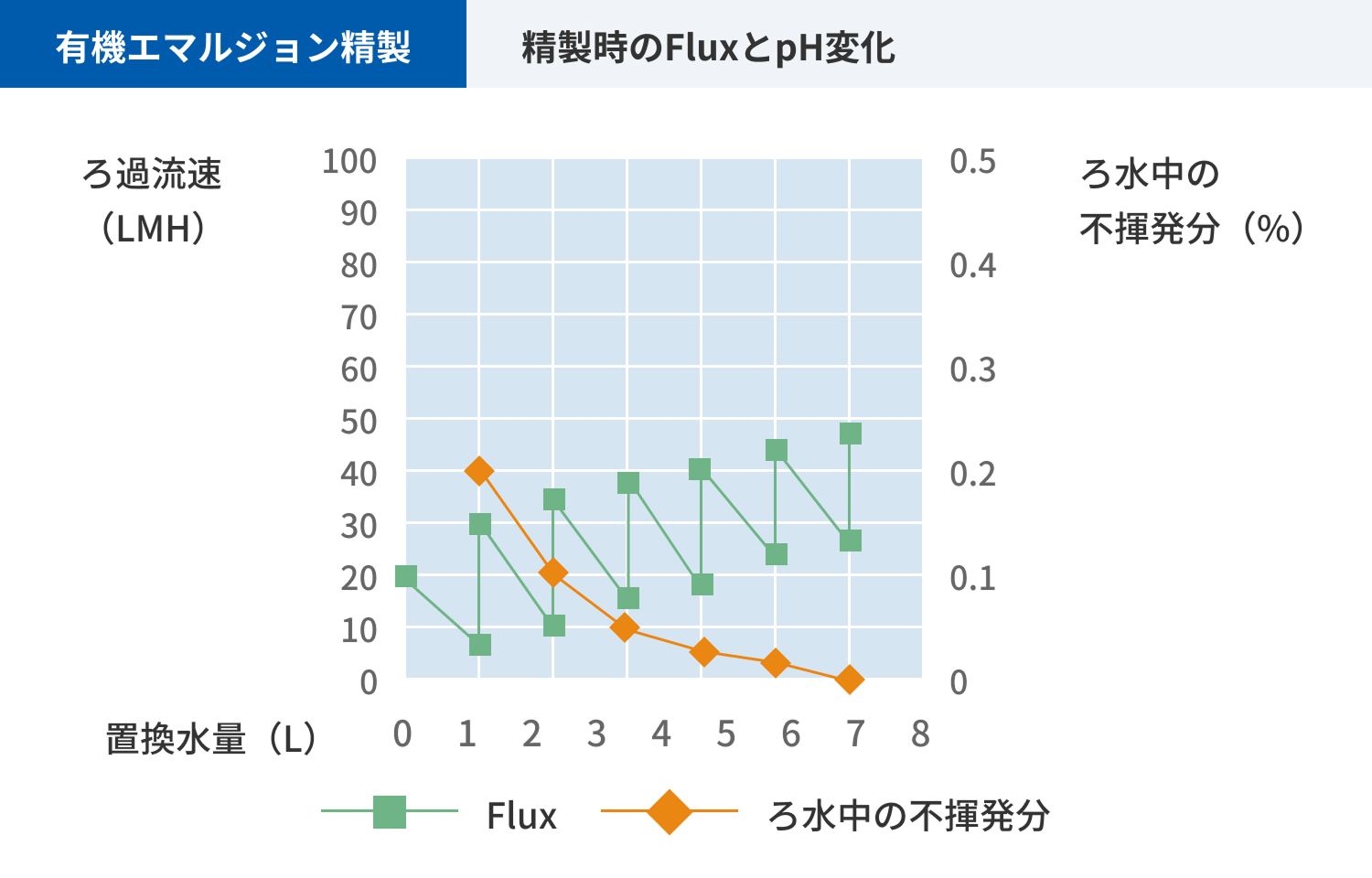

Achieving Both Improved Separation Accuracy and Process Efficiency in Purification

Microza® renewed the process for removing low molecular weight components from Company D's organic emulsion. This case introduces process improvement using filtration technology that combines accuracy and efficiency.

Improved purification efficiency of low molecular weight components.

Company D was seeking a new membrane separation technology to remove low molecular weight components from organic emulsion. Asahi Kasei proposed an efficient and high-precision filtration system using Microza®, resulting in improved purification efficiency of low molecular weight components.

-

Properties of the Target LiquidpH: 3, concentration: 10%, salt concentration: NH4CL=3%, viscosity: 100 mPa·s, conductivity: 40 mS/cm

-

Purpose of Membrane UseRemoval of Low Molecular Weight Substances

-

Purification Method2-fold dilution and 2-fold concentration × 7 cycles

-

Test ConditionTest solution volume: 10 L, pressure: Pi/Po=120/80 kPa, backwash pressure: 140 kPa, backwash cycle: 20 min/20 sec, filtration temperature: 25°C