Reducing Waste in the Production Process by Streamlining Lees Treatment

Optimizing the filtration process in soy sauce production not only reduces costs but also contributes to labor savings and shorter production times. This case study introduces the challenges addressed by Company A using Microza®.

Reducing Losses Associated with Conventional Lees Treatment and Improving Production Efficiency

In soy sauce production, the generation and treatment of lees are unavoidable, and many manufacturers face challenges with product loss and labor. Company A addressed the following issues by introducing Microza®.

-

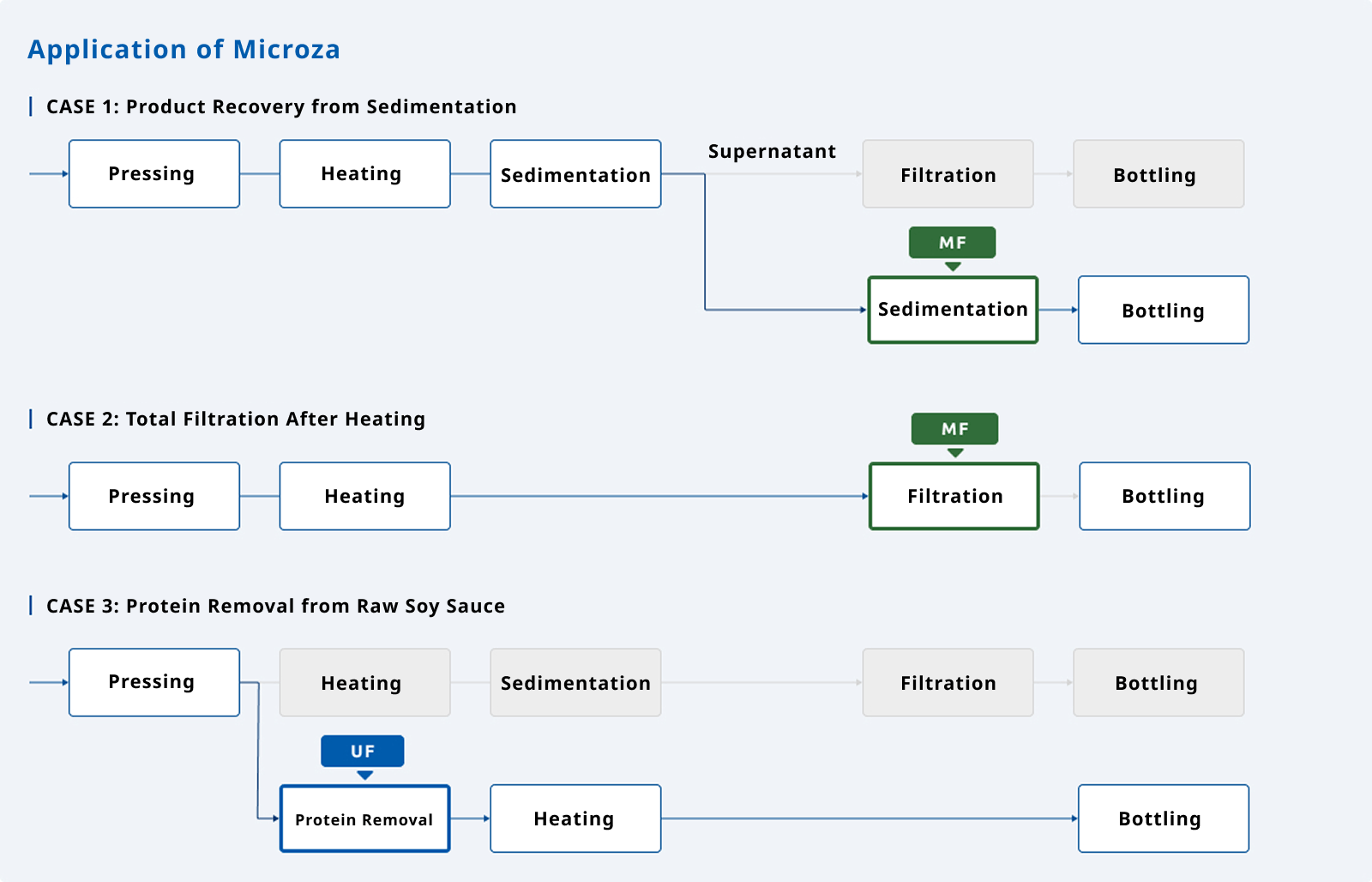

Product Recovery by Filtering Remaining Lees After Lees RemovalSoy sauce previously discarded with remaining lees can now be recovered as product through filtration.

-

Production of Raw Soy Sauce Filtration After PressingBy removing proteins and other precursor components of lees using Microza®, it is possible to produce raw soy sauce with reduced lees generation.

These initiatives have minimized product loss in conventional lees treatment processes and significantly improved production efficiency.

Streamlining Conventional Processes and Reducing Purchase and Disposal Costs to Optimize Total Cost

Many soy sauce manufacturers have used filter aids such as diatomaceous earth in the filtration process. However, the labor and costs for purchasing and disposal have become a significant burden.

Company A introduced Microza® for full-volume filtration of soy sauce after heat treatment. By utilizing Microza®, the conventional lees removal process was eliminated, reducing production time. In addition, since Microza® does not use filter aids such as diatomaceous earth, both purchase and disposal costs were reduced. The reduction in process steps also enabled more efficient use of human resources through labor savings. As a result, waste of raw materials and costs and labor for waste disposal were significantly reduced, greatly optimizing total cost.