High-Performance UF Membrane Trusted in the Chemical Industry

The Industrial Process UF AV/SW Series is a high-performance ultrafiltration membrane module that supports purification and concentration processes in the chemical industry and contributes to environmental protection. It has a proven track record in the purification and concentration of fine powder products, including nanomaterials, fine ceramics, metal oxides, and general-purpose inorganic materials. Asahi Kasei's unique "double skin structure" provides high strength and reliability. In addition, the backwashable design and high chemical resistance enable stable long-term operation.

Details of Industrial Process UF AV/SW Series

Features of Industrial Process UF AV/SW Series

Adopts a cross-flow system to suppress the accumulation of filtered substances on the membrane surface and maintain high water permeability.

Backwashable, with skin layers on both inner and outer surfaces for high compressive strength, reducing the risk of membrane damage.

A lineup with large hollow fiber inner diameters is available, providing a structure that is less prone to slurry clogging.

High chemical resistance allows membrane cleaning with oxidizing agents and supports a wide pH range.

A simple module structure reduces the number of components and dead space, improving liquid quality stability.

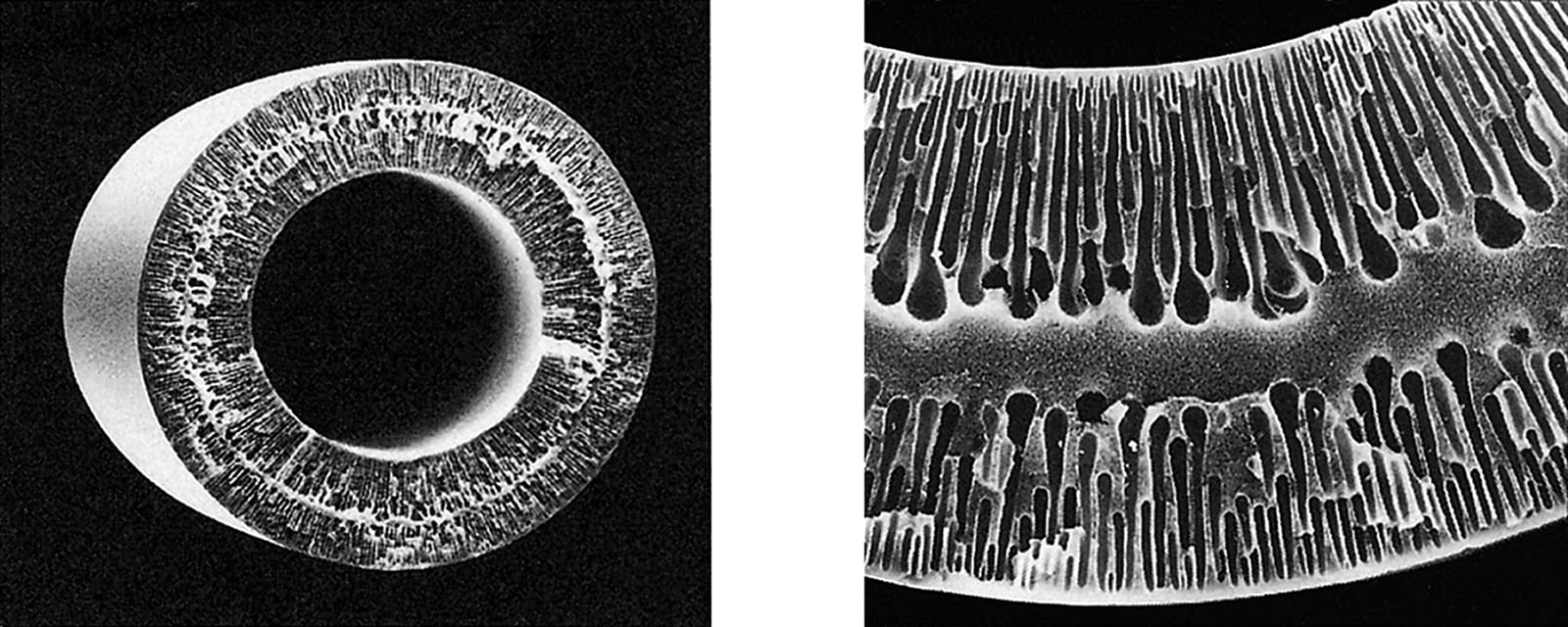

A double skin structure with separation-function skin layers on both inner and outer surfaces ensures high filtration reliability and strength (Learn More Here).

Solutions for Industrial Process UF AV/SW Series

Application Fields by Industry

Chemical Industry: Effective for automation, labor saving, and cleanliness in separation, concentration, and purification processes in chemical manufacturing (Learn More Here)

Application Fields by Use

Purification and concentration of various functional product raw materials (pigments, nanomaterials, rare metal powders, etc.)

Purification and concentration of various fine ceramics raw materials (zirconia, silicon carbide, alumina, etc.)

Purification and concentration of various general-purpose inorganic materials (such as general-purpose colloidal silica)

Purification and concentration of various metal oxides

Purification and concentration of various organic emulsions (Learn More Here)

Recovery of valuable materials and water from process wastewater

Concentration and recovery of proteins and enzymes

Product Specifications of Industrial Process UF AV/SW Series

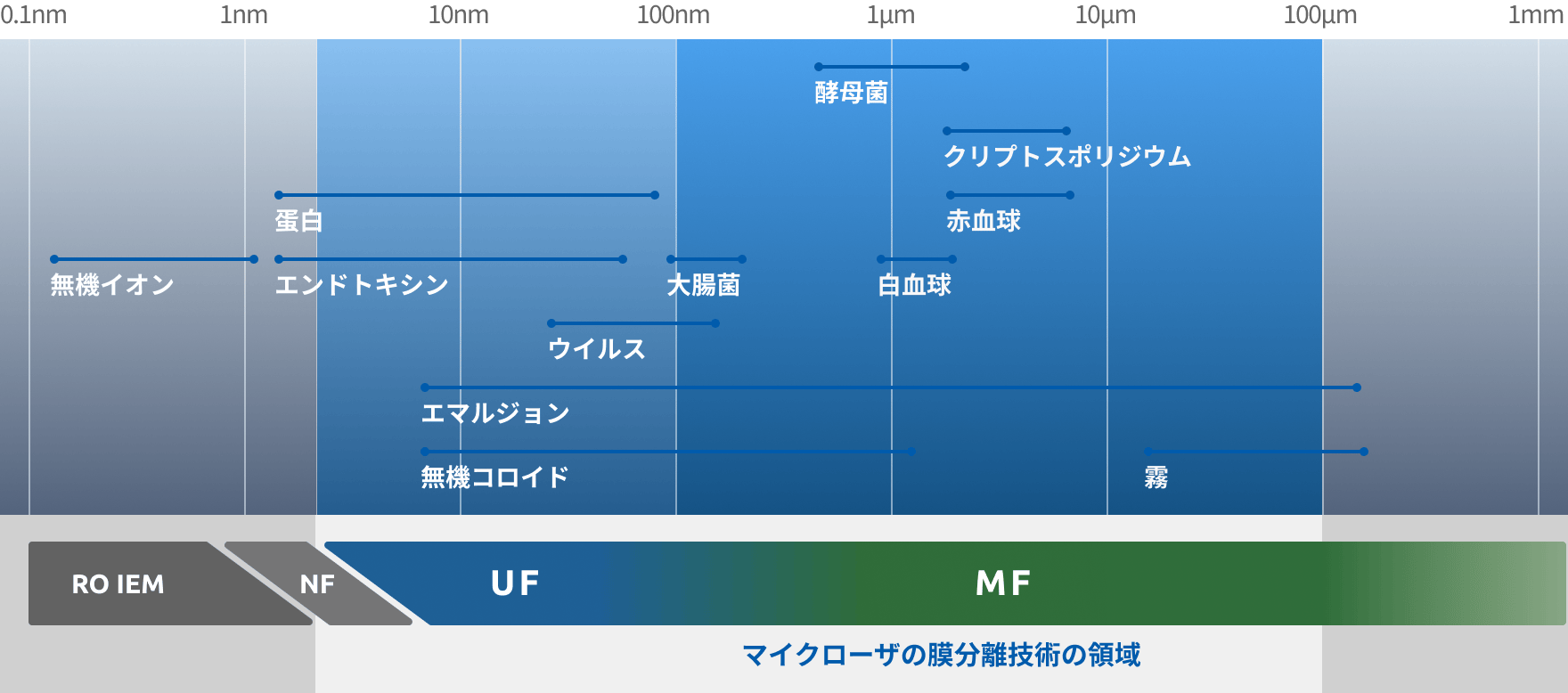

Filtration range of UF membranes capable of removing viruses and macromolecules

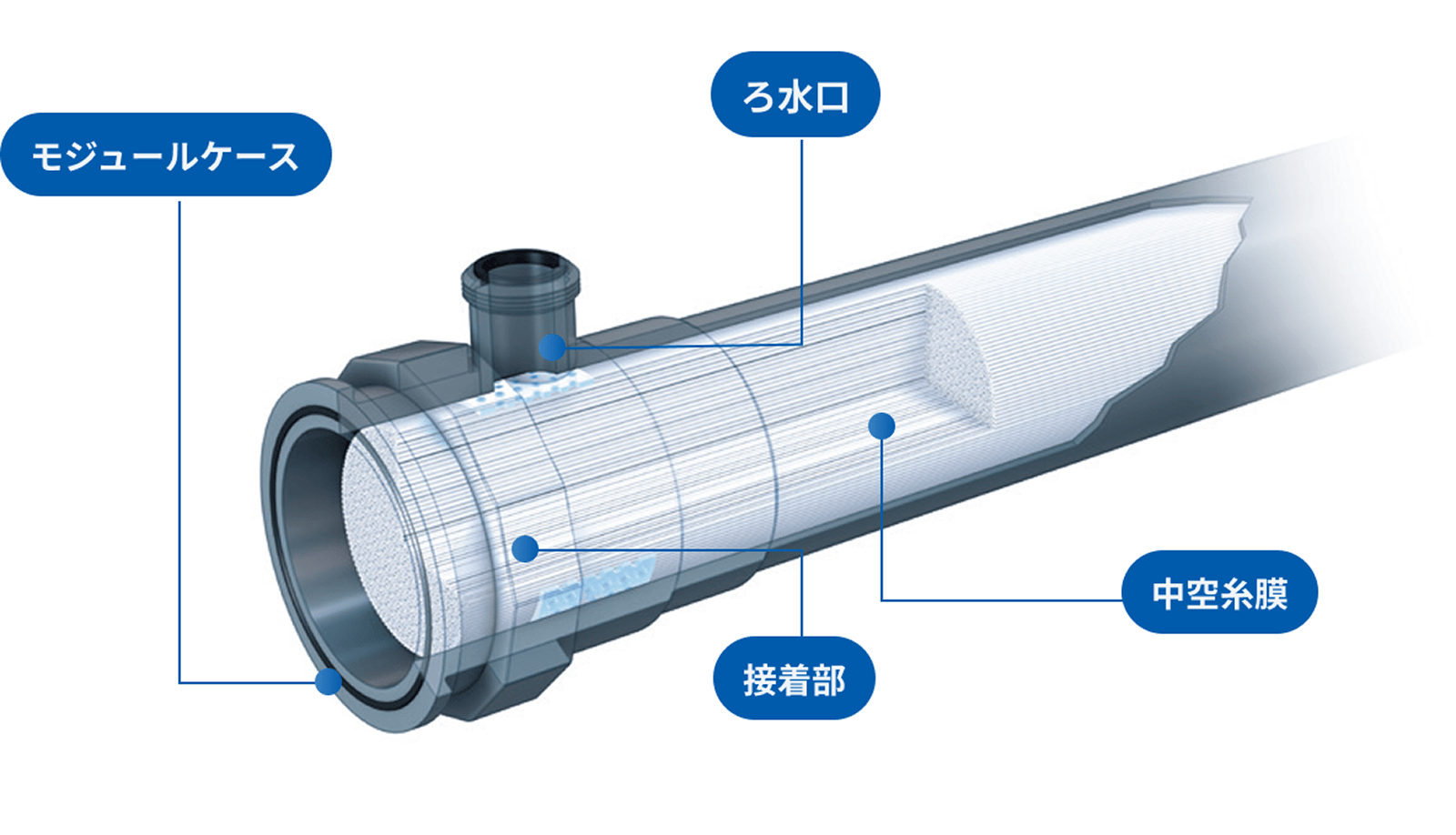

Module Structure

Electron Micrograph of UF Membrane

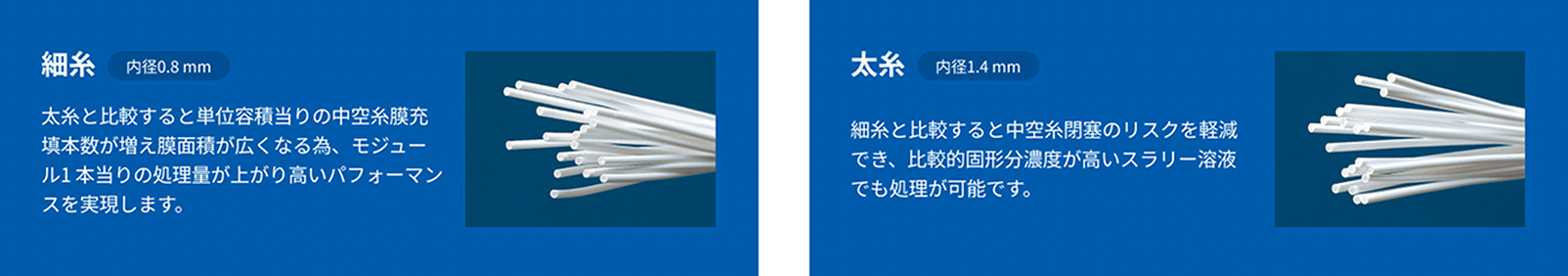

Membrane Inner Diameter

Datasheet

| Model | AV Series | SW Series | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AIV-3013D | ACV-3010D | ACV-3050D | AHV-3010D | ACV-5010D | ACV-5050D | AIV-5010D | SIW-3014 | SIW-3054 | ||

| Material | Hollow Fiber Membrane | Polyacrylonitrile | Polysulfone | |||||||

| Module Case | Polyvinyl chloride | Polysulfone | ||||||||

| Specification | Membrane I.D. (mm) | 0.8 | 1.4 | 0.8 | 1.4 | 0.8 | 0.8 | 1.4 | ||

| Effective Membrane Area (m2) | 4.7 | 3.1 | 4.7 | 12.3 | 7.8 | 12.3 | 5.6 | 4.5 | ||

| Performance | Nominal Molecular Weight Cut-Off | 6,000 | 13,000 | 50,000 | 13,000 | 6,000 | 6,000 | |||

| Initial Permeate Flow Rate* (L/hour at 100 kPa) | 460 | 830 | 420 | 2,500 | 2,200 | 1,100 | 1,050 | 1,200 | 800 | |

| Operating Conditions | Max. Feed Pressure (kPa) | 300 | 200 | 300 | 300 (0-50°C) 200 (51-80°C) |

|||||

| Max. Operating Temperature (°C) | 50 | 80 | ||||||||

| Operating pH Range | 2-10 | 1-14 | ||||||||

| Module Dimensions (mm) | 1,126 L x 89 φ | 1,126 L x 140 φ | 1,126 L x 89 φ | |||||||

| Size | 3 inch | 5 inch | 3 inch | |||||||

| * Initial permeate flow rate is measured using clarified water at 25°C and 100 kPa. | ||||||||||