Next-Generation UF Membrane Supporting Advanced LSI Manufacturing

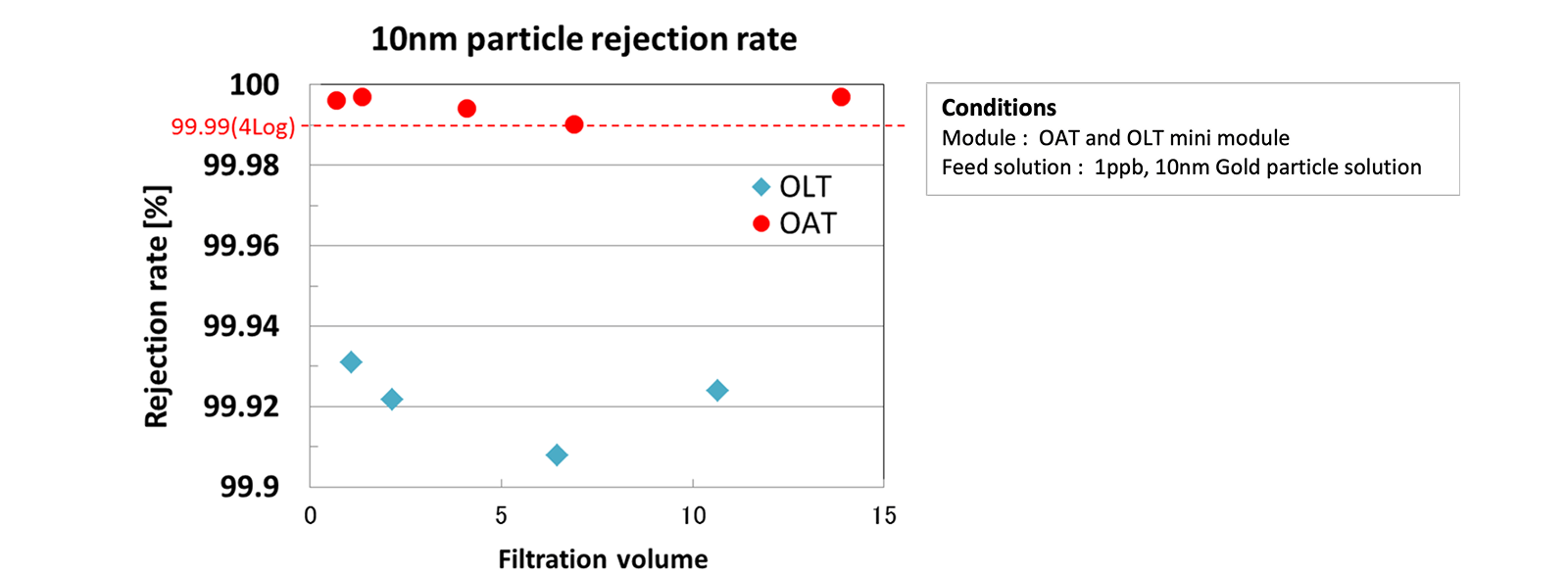

The OAT Series is a next-generation UF membrane module evolved from the globally proven OLT Series. With high-performance filtration that removes 99.99% of 10 nm particles and thorough cleanliness management, it provides a stable supply of ultrapure water for advanced LSI manufacturing.

Details of the Water Treatment Process OAT Series

Features of the Water Treatment Process OAT Series

Double-skin structure that collects filtered water from both ends of the module to reduce pressure loss and achieves high water quality with dense membrane structure on both inner and outer surfaces (Learn More Here).

Achieves 99.99% removal rate of 10 nm particles, providing maximum effectiveness in reducing particles in filtered water.

Long-term storage under specified conditions* is possible by filling with heat-sterilized pure water. *In a cool, dark place away from direct sunlight.

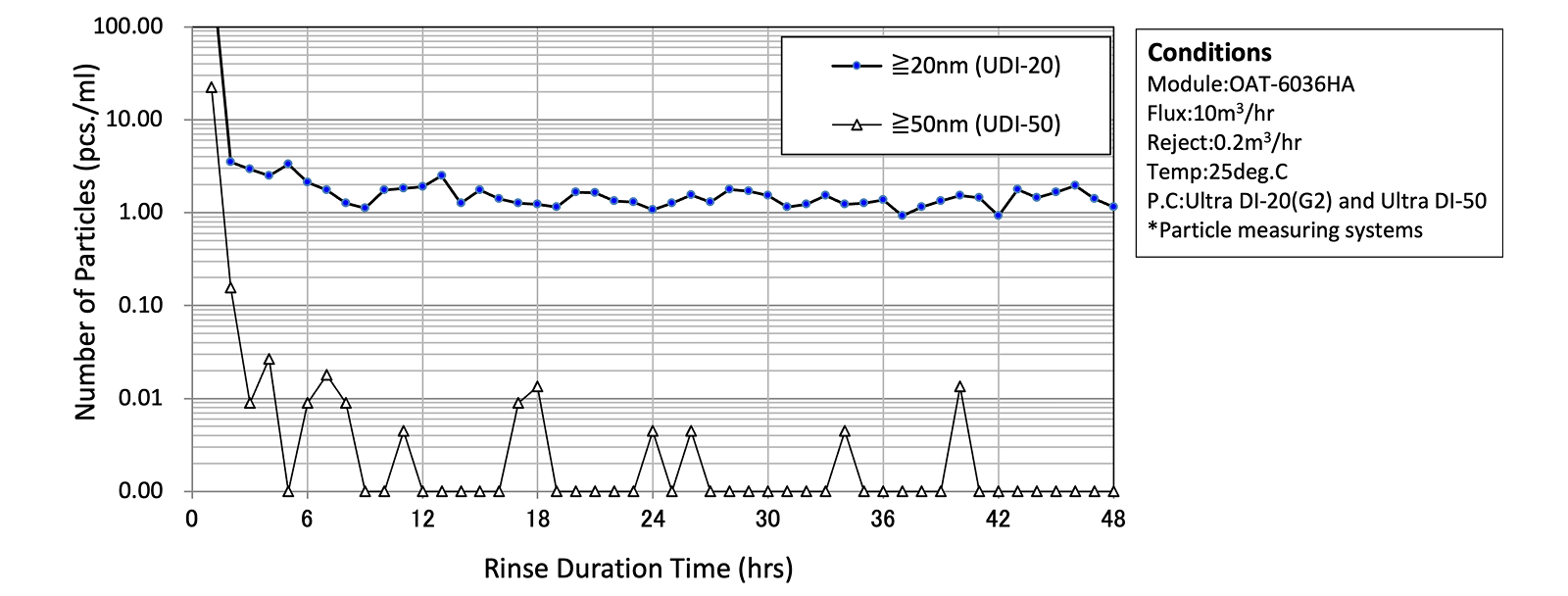

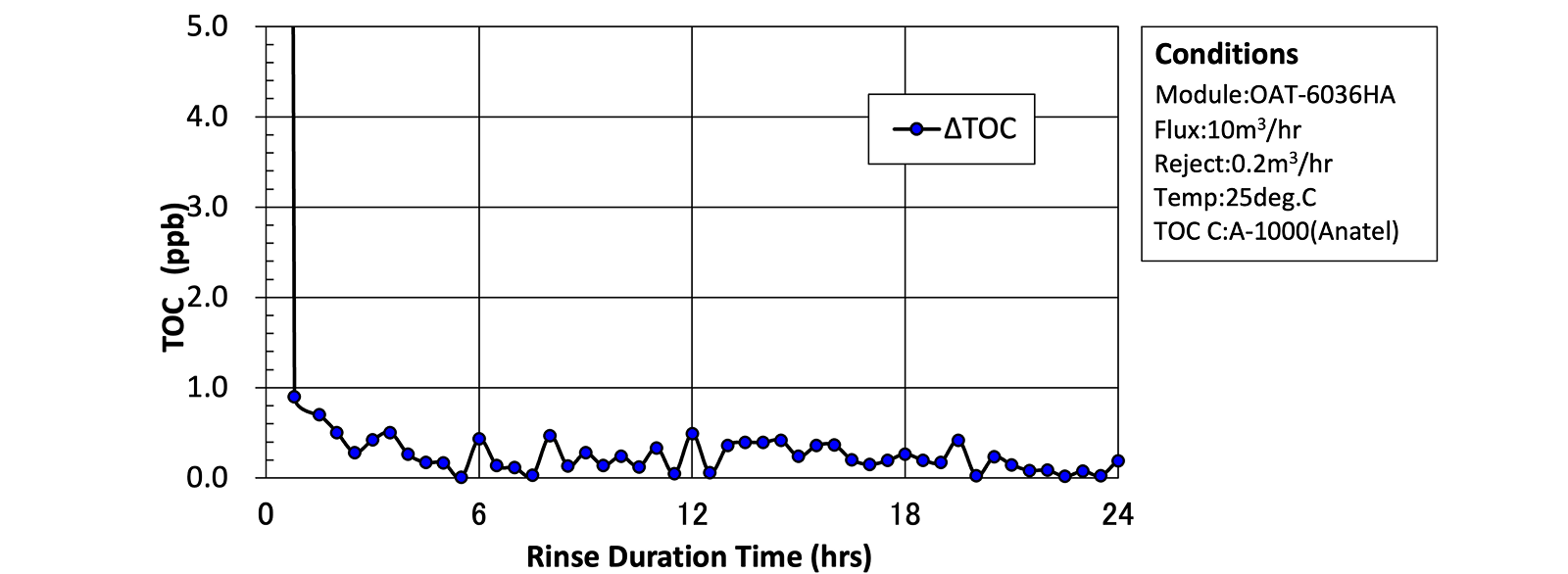

High cleanliness enables rapid stabilization of particles, TOC, and specific resistance.

A wide lineup is available, including a pressure-resistant type rated at 1,200 kPa (40°C) and a heat- and pressure-resistant type rated at 800 kPa (80°C).

Solutions for the Water Treatment Process OAT Series

Application Fields by Industry

Electronics Industry: Improves the quality of ultrapure water used in semiconductor and LCD manufacturing through advanced impurity removal performance and stable operation (Learn More Here).

Application Fields by Use

Ultrapure Water Production Process in Advanced LSI Factories (Learn More Here).

Product Specifications of the Water Treatment Process OAT Series

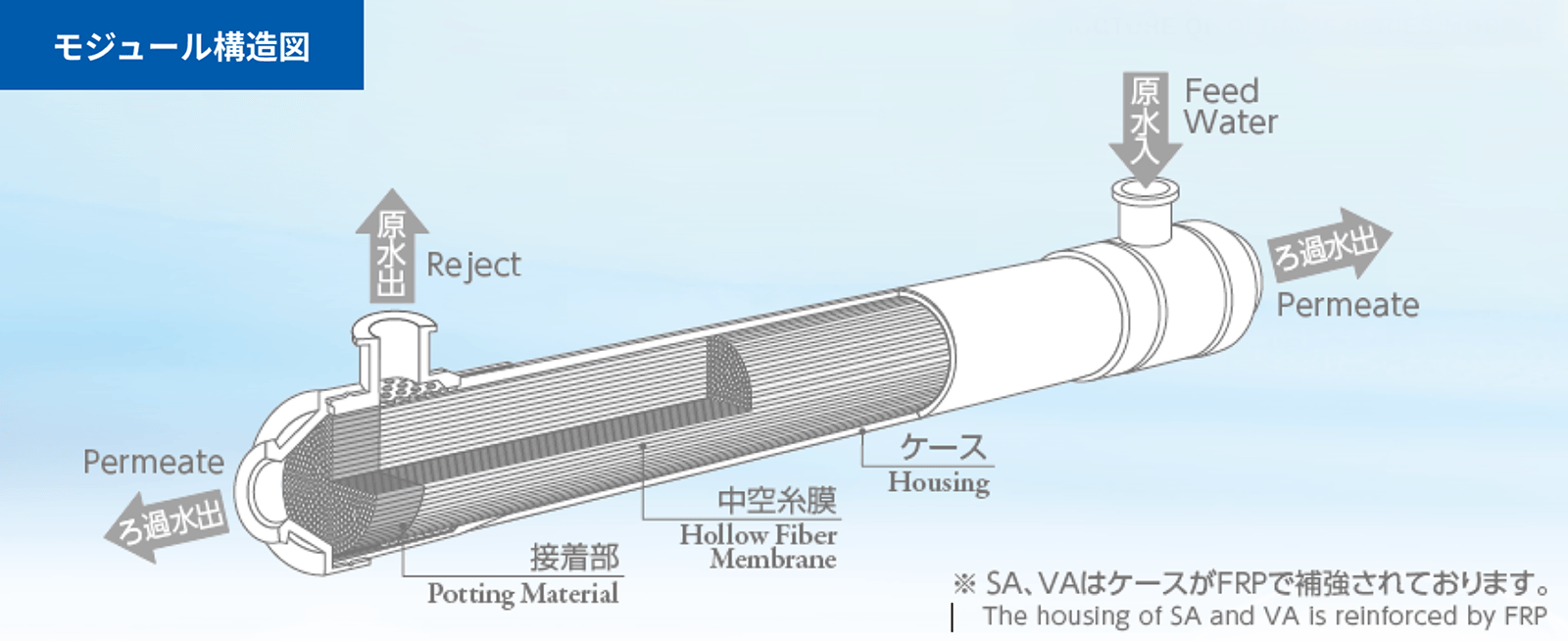

Module Structure

Datasheet

| Model | OAT-6036 Series | |||||||

|---|---|---|---|---|---|---|---|---|

| OAT-6036HA | OAT-6036SA | OAT-6036VA | ||||||

| Specification | Effective Membrane Area | 34 m2 | ||||||

| Module Length | 1,177 mm | |||||||

| Module Diameter | 172 mm | 179 mm | ||||||

| Performance | Nominal Molecular Weight Cut-Off | 4,000 | ||||||

| Nominal Pore Size | 2 nm | |||||||

| Recommended Design Filtrate Volume | ≦12 m3/h (*1) | |||||||

| Operating Conditions | UF Feed Water Temperature | 25°C (*2) | 25°C (*2) | 40–69°C | 70–80°C | |||

| Max. Transmembrane Pressure | 300 kPa | 300 kPa | 200 kPa | 100 kPa | ||||

| Max. Feed Water Pressure | 900 kPa | 1,200 kPa | 900 kPa | 800 kPa | ||||

| Max. Filtrate Side Pressure | 900 kPa | 1,200 kPa | 900 kPa | 800 kPa | ||||

| Main Materials | Hollow Fiber Membrane | Polysulfone-based | ||||||

| Module Case | Polysulfone-based | Polysulfone-based with FRP Reinforcement | ||||||

| Adhesive | Epoxy Resin | |||||||

| Gasket | Fluororubber | |||||||

| *1: For information on the relationship between filtrate pressure and volume, and between water temperature and filtrate pressure, please refer to the module’s instruction manual. *2: Up to 90°C for hot water sterilization. | ||||||||