High-Performance MF Membrane for a Wide Range of Applications

Industrial Process MF is a hollow fiber membrane product that provides highly efficient separation technology for concentration and purification processes. With a wide range of membranes, it enables automation, labor saving, and cleanliness in separation and purification processes across pharmaceuticals, food, chemical industries, and more.

Details of Industrial Process MF

Features of Industrial Process MF

The U Series uses high-strength PVDF membranes, providing excellent chemical resistance and long-term stable operation.

With a proven track record, it is used for purification and concentration in various fields such as food, pharmaceuticals, and chemical industries.

The extensive lineup allows users to select the optimal membrane for their application, including pore size, membrane area, material, and inner diameter.

Backwash capability (reverse pressure cleaning) enables backwashing of filtered water due to the robust membrane structure.

Compared to ceramic membranes, it saves space and reduces energy consumption and power costs.

Industrial Process MF Solutions

Application Fields by Industry

Food: Contributes to improved productivity in separation and filtration processes in the food industry through both software and hardware approaches (Learn More Here)

Pharmaceuticals: Achieves increased yield and productivity of target substances (antibodies, proteins, vaccines, enzymes, etc.) (Learn More Here)

Chemical Industry: Effective for automation, labor saving, and cleanliness in separation, concentration, and purification processes in chemical manufacturing (Learn More Here)

Application Fields by Use

Replacement for diatomaceous earth filters (Learn More Here)

Replacement for centrifuges

Sterilization and purification of broth

Concentration and purification of microbial cells (cell collection and washing)

Sterilization and clarification of food ingredients

Concentration and purification of colloidal substances

Recovery of valuable substances from other aqueous solutions

Product Specifications of Industrial Process MF

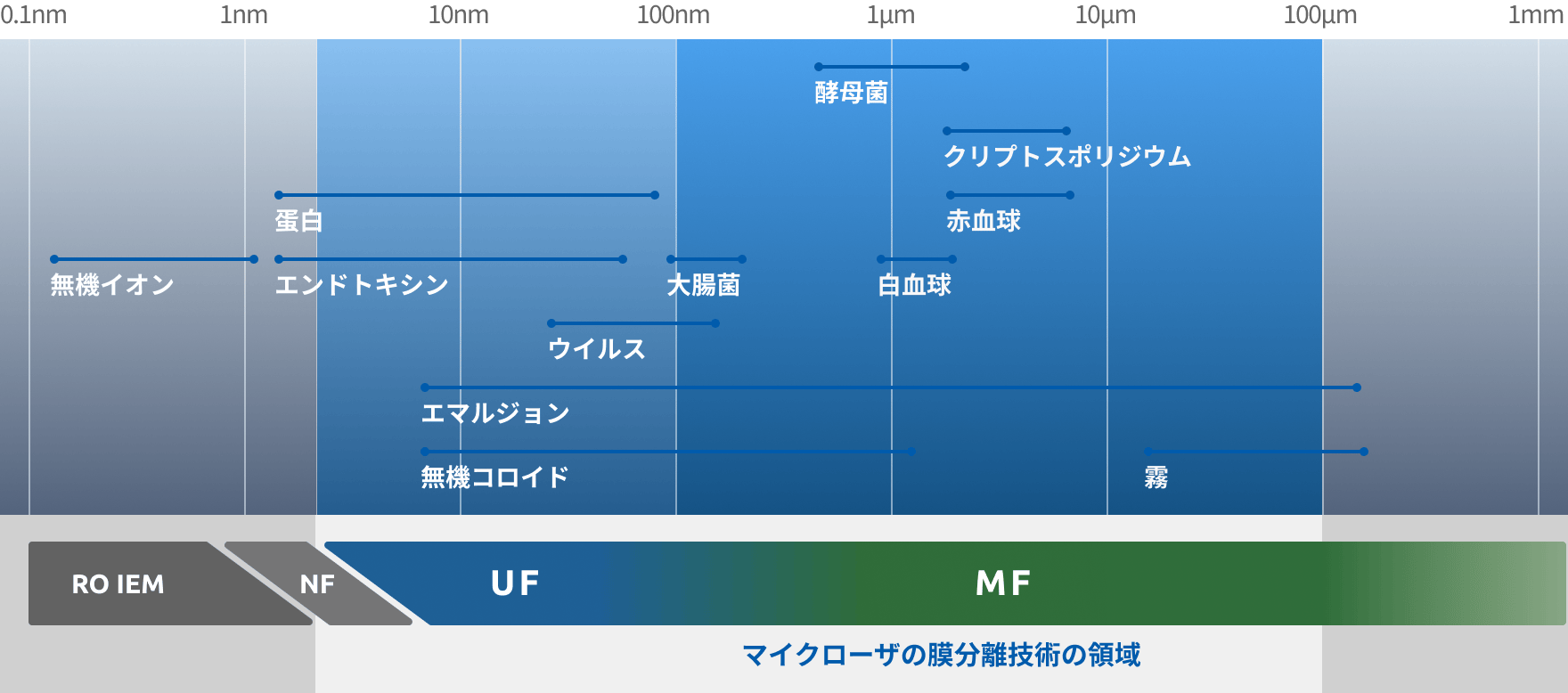

Filtration Range of MF Membranes Capable of Handling Fine Particles to Microorganisms

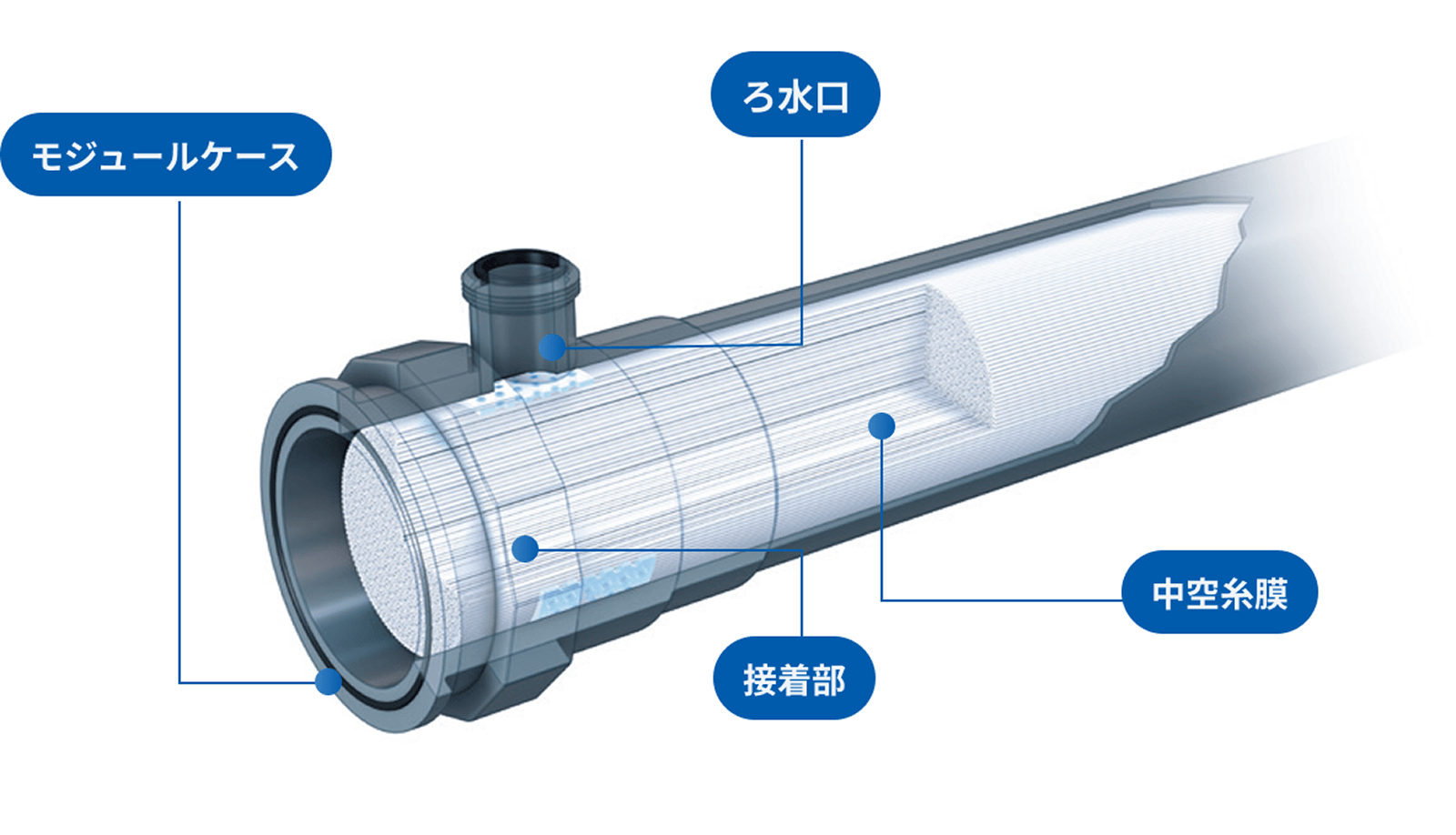

Module Structure

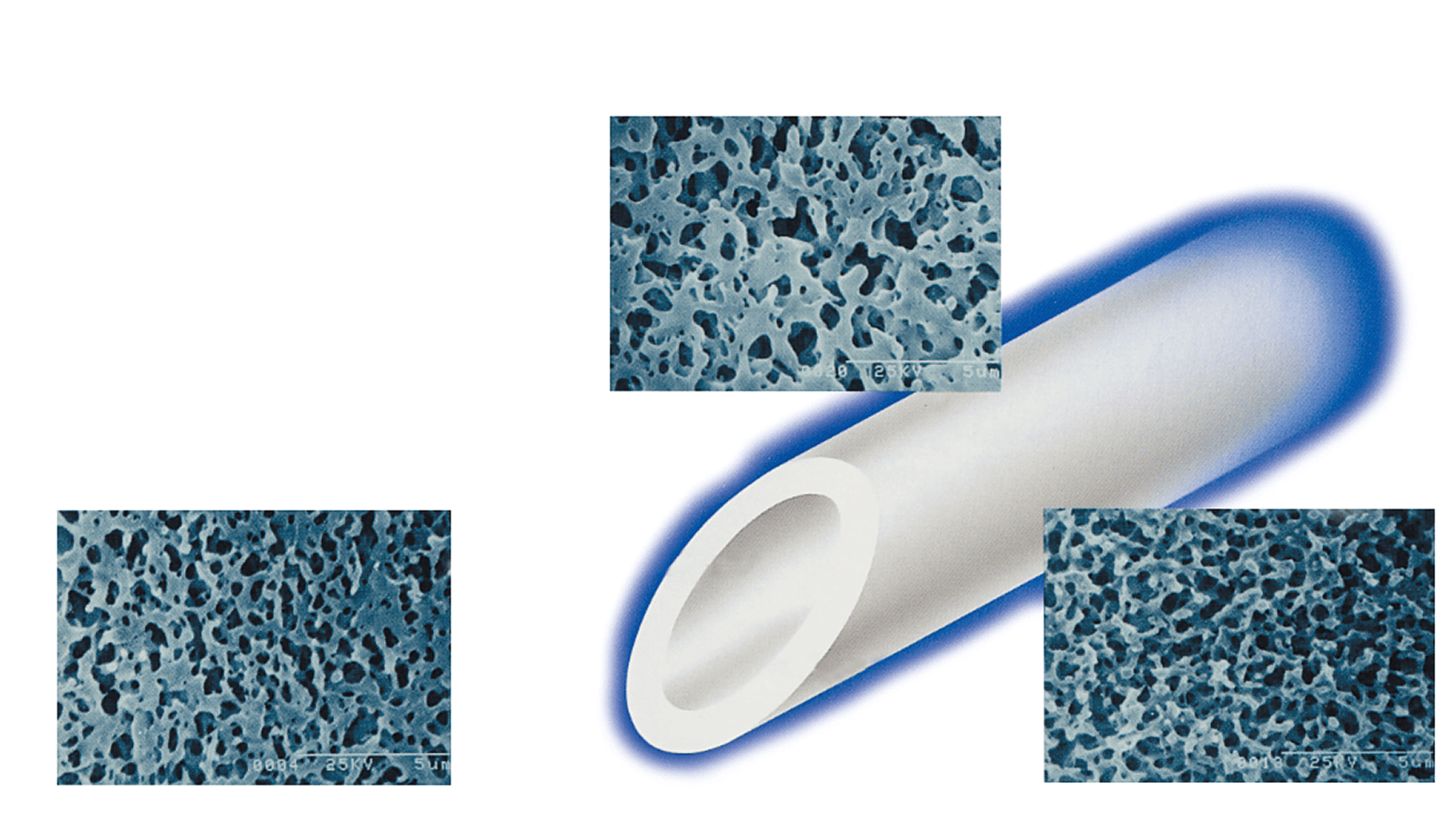

Electron Micrograph of MF Membrane

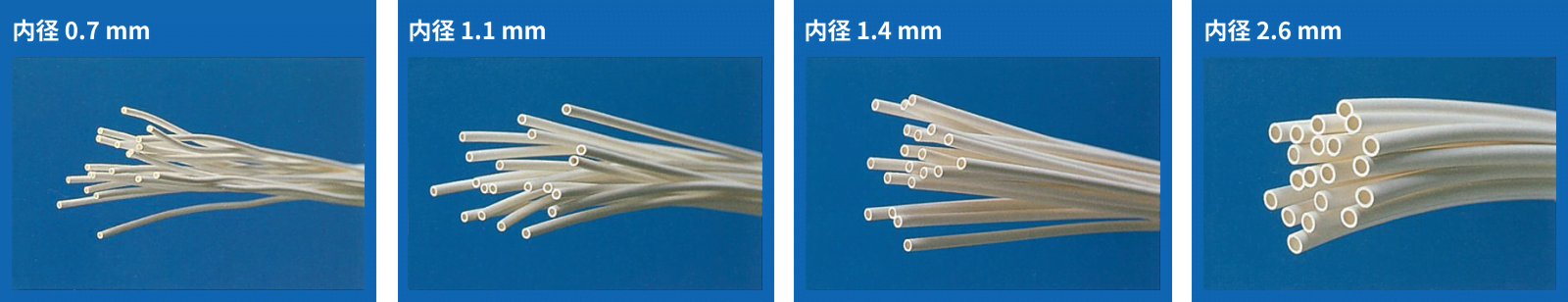

Membrane Inner Diameter

Datasheet - U Series

| Model | U Series | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| USP-343 | UMP-353 | ULP-343 | USW-543 | UMW-553 | USP-6443 | UTP-6443 | |||

| Material | Hollow Fiber Membrane | Polyvinylidene fluoride | |||||||

| Module Case | Polysulfone (transparent) |

Polysulfone (white) |

Polysulfone (transparent) |

||||||

| Specification | Membrane I.D. (mm) | 1.4 | 2.6 | 1.1 | 1.4 | 2.6 | 1.4 | 1.4 | |

| Effective Membrane Area (m2) | 3.7 | 2.2 | 3.8 | 8.8 | 5.0 | 17.4 | 21.5 | ||

| Performance | Nominal Pore Size (µm) | 0.1 | 0.2 | 0.45 | 0.1 | 0.2 | 0.1 | 0.2 | |

| Initial Permeate Flow Rate* (L/hour) | 440 | 200 | 1,200 | 1,050 | 500 | 1,500 | - | ||

| Operating Conditions | Max. transmembrane pressure (kPa) | (0–80°C) | 300 | 300 | 300 (0–70°C) | 300 (0–70°C) | |||

| (81–95°C) | 100 | 100 | - | - | |||||

| Max. Operating Temperature (°C) | Normal Use | 80 | 70 | 70 | |||||

| Hot Water Sterilization | 95 | ||||||||

| Operating pH Range | 1–10 | ||||||||

| Module Dimensions (mm) | 1,129 L x 89 φ | 1,172 L x 140 φ | 1,512 L x 165 φ | 1,512 L x 165 φ | |||||

| Size | 3 inch | 5 inch | 6 inch | ||||||

| * Indicates the initial filtrate volume when filtering clarified water at 25°C and 100 kPa. | |||||||||

Datasheet - P Series

| Model | P Series | |||||||

|---|---|---|---|---|---|---|---|---|

| PSP-303 | PSV-303 | PMP-302 | ||||||

| Material | Hollow Fiber Membrane | Polyethylene | ||||||

| Module Case | Polysulfone (transparent) | Polyvinyl chloride | Polysulfone (transparent) | |||||

| Specification | Membrane Inner Diameter (mm) | 0.7 | 0.7 | |||||

| Effective Membrane Area (m2) | 6.0 | 5.0 | ||||||

| Performance | Nominal Pore Size (µm) | 0.1 | 0.25 | |||||

| Initial Permeate Flow Rate*Initial Permeate Flow Rate* (L/hour) | 700 | 1,000 | ||||||

| Operating Conditions | Maximum Differential Pressure Across Membrane (kPa) | (0~80°C) | 220 | 220 | 200 | |||

| (81~95°C) | 130 | 130 | - | |||||

| (81~95°C) | 70 | - | - | |||||

| Maximum Operating Temperature (°C) | Normal Use | 60 | 50 | 30 | ||||

| Allowable pH Range | 1-14 | |||||||

| Module Dimensions (mm) | 1,129 L x 89 φ | 1,126 L x 89 φ | 1,129 L x 80 φ | |||||

| Size | 3 inch | |||||||

| * Indicates the initial filtrate volume when filtering clarified water at 25 °C and 100 kPa. | ||||||||