Transition from Diatomaceous Earth Filtration to Membrane Method

Conventional diatomaceous earth filtration presents many challenges, such as high costs and large amounts of industrial waste. Here, we present a case where the clarification process was renewed using Microza®, achieving both economic and environmental benefits.

Switching to Microza® Reduces Filtration Aid Costs and Waste

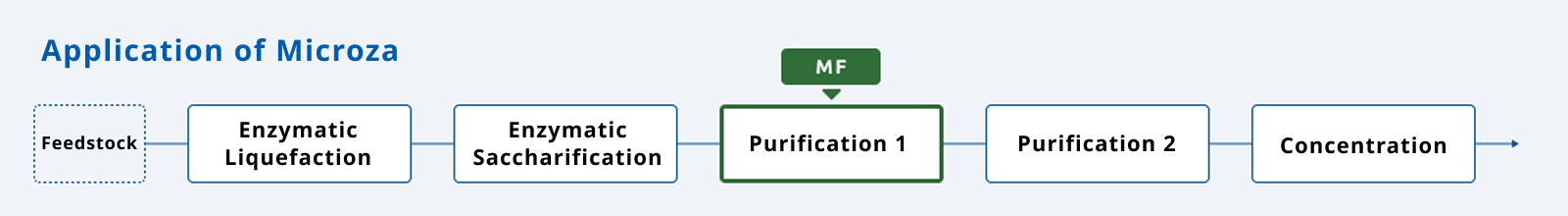

In the clarification process for sugars, it is essential to remove suspended solids and coloring components generated after saccharification to improve product purity. While conventional diatomaceous earth filtration is effective for clarification, it incurs high filtration aid costs, generates large amounts of industrial waste after use, and faces issues such as aging drum filters.

Company A implemented Asahi Kasei's hollow fiber membrane product, Microza® MF membrane, to achieve a clarification process independent of diatomaceous earth filtration. Microza® MF membrane eliminates the need for filtration aids, ensures high purity and clarity, and reduces both costs and waste, balancing economic and environmental considerations.

Successful Transition with Asahi Kasei's Accompanied Support

The clarification process is a critical step in a company's production process, and switching from conventional manufacturing methods requires significant consideration. Issues such as necessary capital investment, compatibility with existing lines, and impacts on operation tests and quality control are not easily resolved.

In this case, we carefully listened to the customer's existing equipment and production conditions, developed the optimal introduction scenario together, and provided consistent support from trial introduction to operational follow-up. We accurately identified and addressed each challenge related to the equipment transition, helping the customer achieve their desired manufacturing goals.