Achieving Both Highest Water Purity and Energy Savings

WFI (Water For Injection) systems provide a stable supply of high-purity water while reducing CO2 emissions and energy costs. Comprehensive support, including remote monitoring, routine maintenance, and troubleshooting, also contributes to lower overall lifecycle costs.

Achieving Higher Water Purity

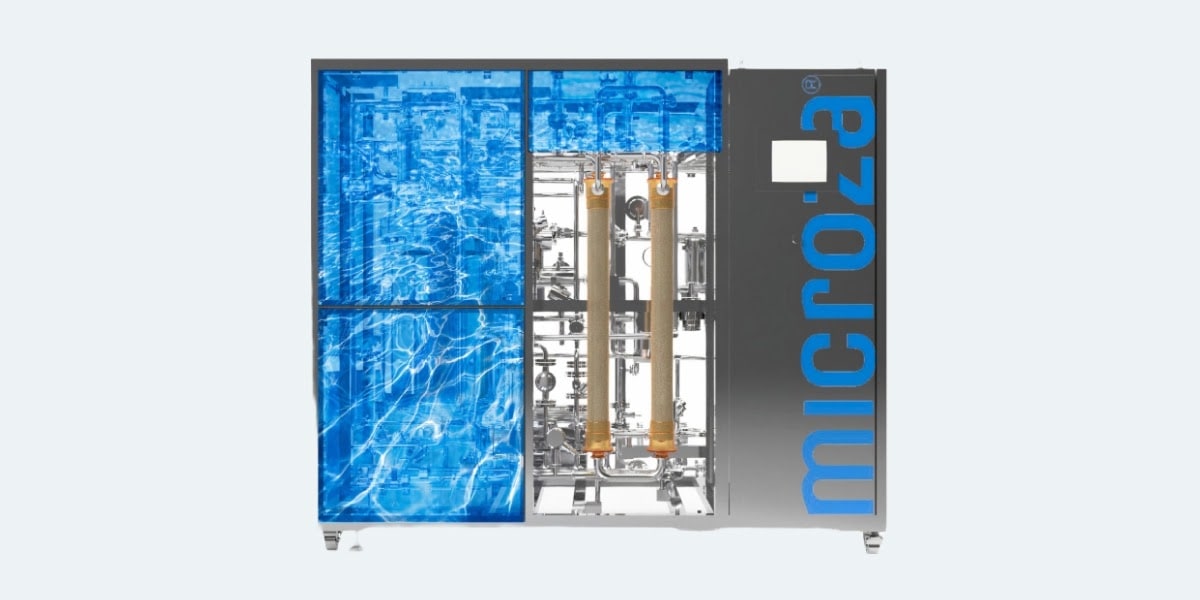

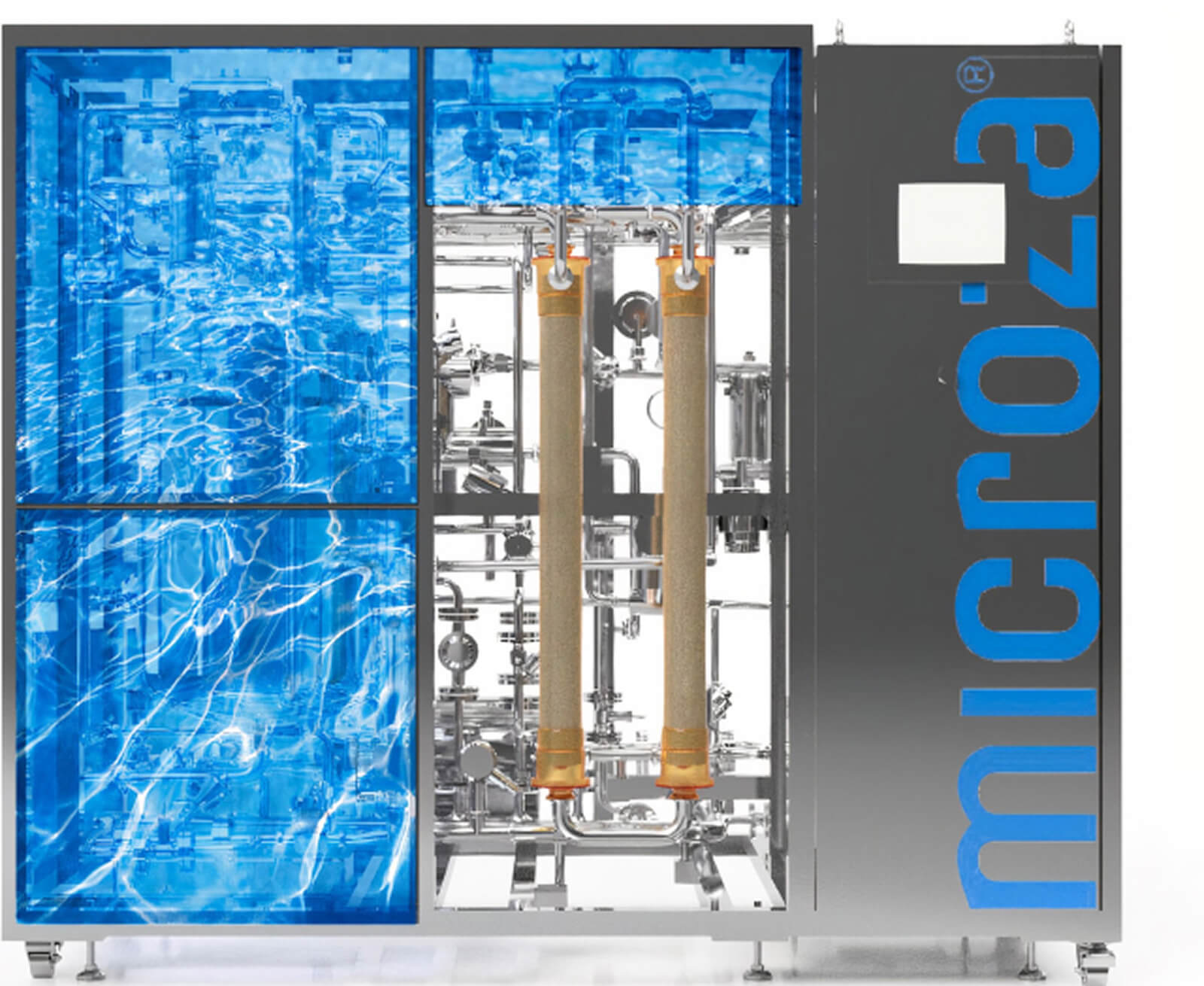

The WFI equipment equipped with Asahi Kasei's high-performance UF membrane directly blocks impurities such as endotoxins, enabling stable production of high-purity water. The absence of the steam cooling process required in conventional distillation methods simplifies the equipment structure and reduces the risk of foreign matter contamination. This combination of physical size exclusion and simple equipment design enables efficient production of higher-purity water.

CO2Contributes to Reduced Emissions and Lower Energy Costs

In conventional distillation methods, large amounts of steam are generated and then cooled to produce water for injection. In contrast, WFI equipment using Microza® hollow fiber membranes eliminates the need for energy-intensive distillation. This significantly reduces CO2 emissions and energy costs compared to conventional methods.

Ensuring High Hygiene Through Steam Sterilization

Generally, membrane-based water for injection production ensures high water purity, but some may be concerned about whether hygiene is equivalent to distilled water. Asahi Kasei addresses this by designing equipment that can be steam sterilized (SIP) in its entirety, unlike other membrane systems, ensuring hygiene equivalent to distilled water. This enables both high water quality and hygiene, providing greater assurance.

Stable Operation Supported by Remote Monitoring and Regular Maintenance

Asahi Kasei provides a service system combining remote monitoring and regular maintenance after WFI equipment installation, supporting continuous optimal operation.

Monitoring of Operating Status by Remote Monitoring (Twice Daily)

Regular checks of data such as pressure, flow rate, temperature, tank water level, and bio-particles enable early detection of abnormalities. Prompt response helps prevent problems before they occur.

Comprehensive Inspection Every Six Months to Maintain Normal Operation

Air leak inspections, replacement of consumables, and steam sterilization as needed are performed to maintain high levels of hygiene and performance.

Membrane Replacement Every Two Years

By regularly replacing the membranes and preventing performance degradation due to aging, stable production of high-purity water can be achieved.

This comprehensive service structure not only ensures long-term, reliable use of WFI equipment, but also contributes to cost reduction throughout the entire lifecycle. Asahi Kasei provides consistent support from pre-installation to post-installation, strongly supporting improvements in customers' production systems and stable operation.

WFI Equipment Product Specifications

| Membrane Type | VIP-3017 |

| Membrane Material | Polysulfone |

| Nominal Molecular Weight Cut-Off | 6,000 |

| Standard Design Filtration Flow Rate | 0.5 m3/h (per module) |

| Standard Hot Water Sterilization Temperature | Up to 85°C |

| Standard Steam Sterilization Temperature | 121–125°C |

| External Dimensions (Based on 2 Modules) | 1,200 x 2,200 x 1,900 mmH |