Membrane Filtration Methods

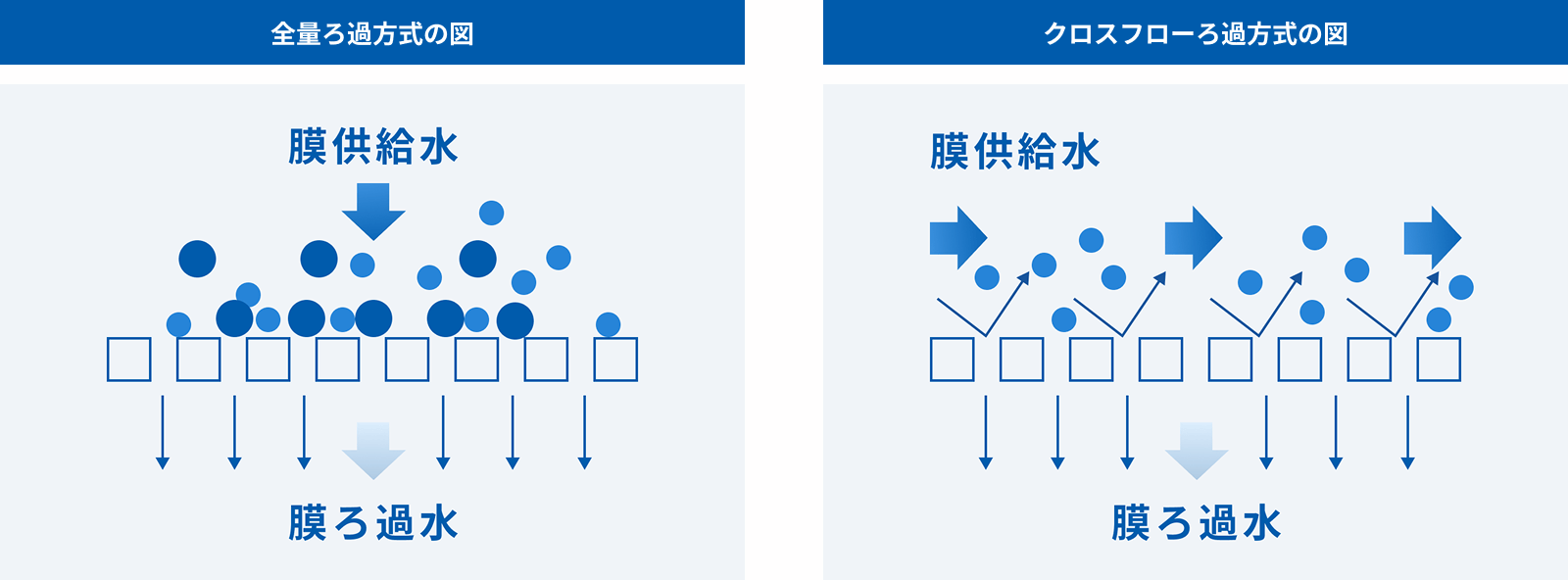

Generally used membrane filtration methods are total filtration and cross-flow (also called tangential flow) filtration methods.

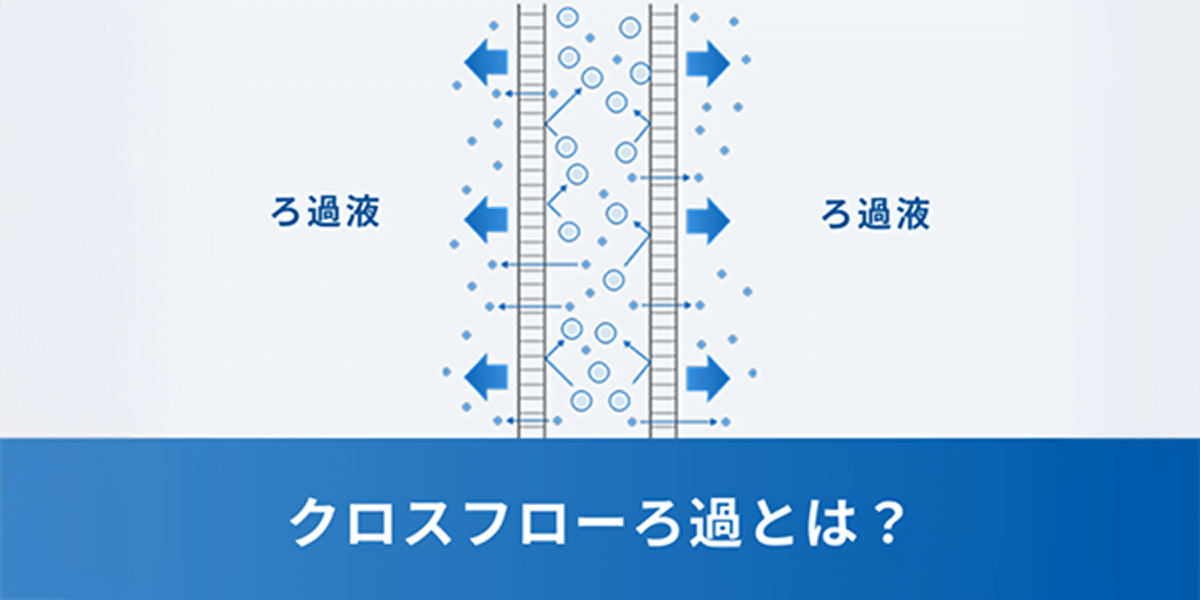

The total filtration method filters all of the feed water, similar to conventional sand or paper filtration. Because separated substances accumulate on the membrane surface, periodic cleaning or membrane replacement is required. In contrast, the cross-flow filtration method creates a flow parallel to the membrane surface, suppressing the accumulation of suspended solids and colloids on the membrane during filtration.

The filtration method is closely related to raw water quality, membrane material and separation performance, module structure, and cleaning method. It is necessary to select a method suitable for the treatment conditions.

From a cost perspective, the total filtration method does not require parallel flow like cross-flow filtration, resulting in lower power costs, but cleaning or membrane replacement is needed at relatively short intervals. In cross-flow filtration, higher membrane surface velocity generally suppresses the accumulation of substances on the membrane, resulting in higher filtration flux. High membrane surface velocity is preferable for preventing membrane fouling. However, higher membrane surface velocity increases power costs, so it is necessary to design an economical membrane surface velocity based on the relationship between treated water volume and cleaning effectiveness.

Source: Japan Water Works Association "Q&A on Membrane Filtration Methods in Waterworks with Glossary of Water Filtration Terms" (partially modified)

Click here for tips on solving issues related to filtration and separation.

Asahi Kasei's hollow fiber membrane Microza® for filtration and separation is used in a wide range of fields, including pharmaceuticals, pharmaceutical water, food, chemicals, semiconductors, as well as power, water supply, and industrial water. Please see here for Microza® applications, solutions by industry, and case studies.