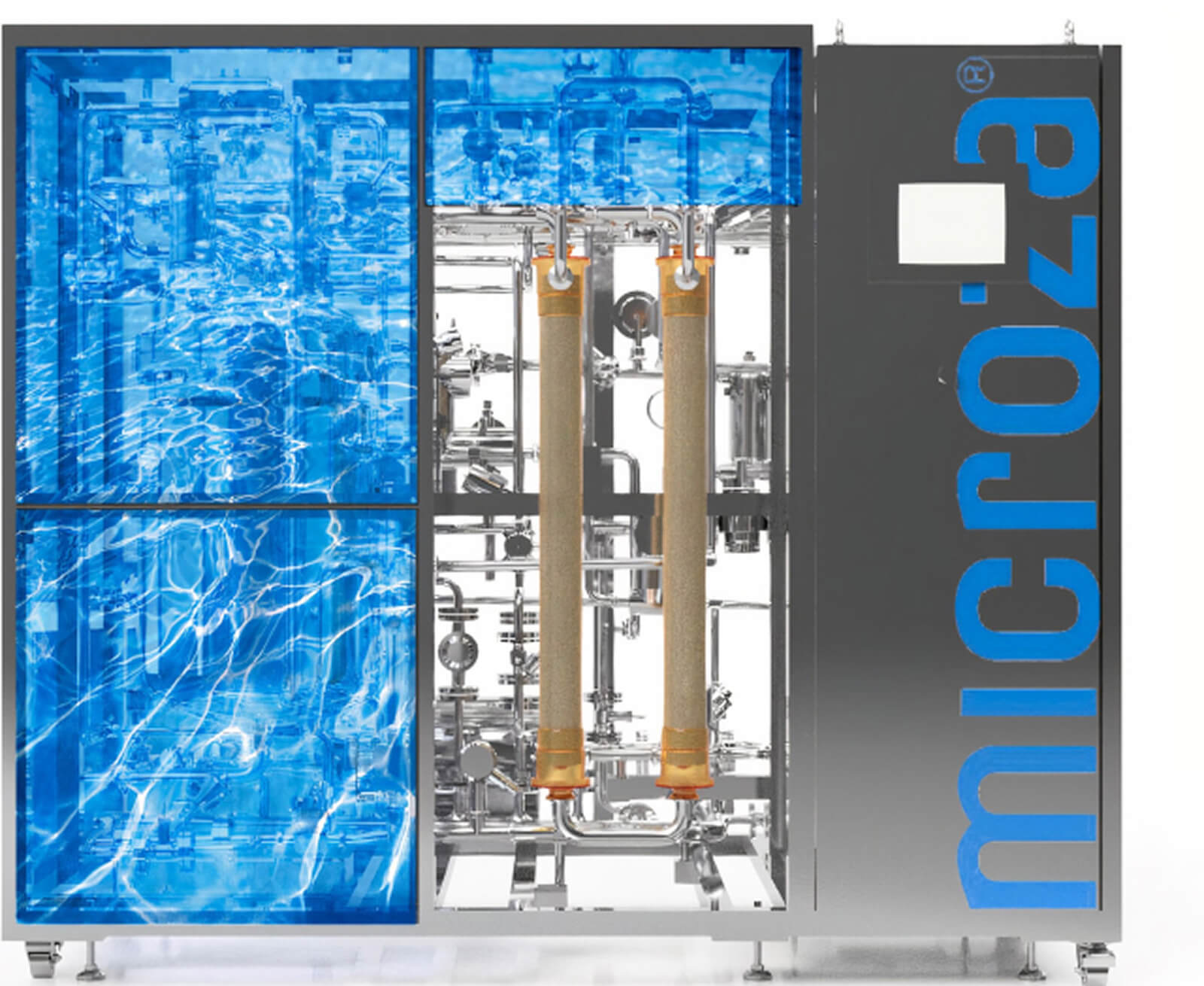

The Membrane and Water Treatment Division has launched the sale of a standard unit for the production of Water for Injection (WFI).

The method of producing Water for Injection (WFI) using distillation, which is commonly used in Japan, CO2has issues such as high emissions, risk of foreign matter contamination, and high initial and running costs. By introducing our standard WFI equipment, it is possible to reduce energy consumption in the manufacturing process compared to the distillation method, as well as lower the risk of foreign matter contamination and improve economic efficiency.

Features of Our Water for Injection (WFI) Production Equipment

-

CO2Reduction of Emissions and Energy Costs PossibleCompared to the distillation method, steam usage can be reduced, resulting in CO2It is possible to reduce emissions and energy costs.

-

Process simplification is possible.Because the process of condensing steam into liquid, which is required in distillation, is unnecessary, the process can be simplified.

-

Higher water quality.Compared to distillation, it offers higher endotoxin removal performance and a lower risk of foreign matter contamination, enabling higher water quality.

-

High level of hygiene through steam sterilization.Unlike other membrane systems, our equipment can be steam sterilized, ensuring hygiene equivalent to distilled water.

Product Overview

Product name: WFI Standard System

Membrane type (material): VIP-3017 (polysulfone) *Steam sterilizable

Nominal Molecular Weight Cut-Off: 6,000

Standard design filtration water volume: 0.5 m3/h (per module)